Rapid deployment flood control system

a flood control and rapid technology, applied in the field of rapid deployment flood control system, can solve the problems of large amount of land, high cost of engineering and construction, and destruction of valuable historic and ecologic treasures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

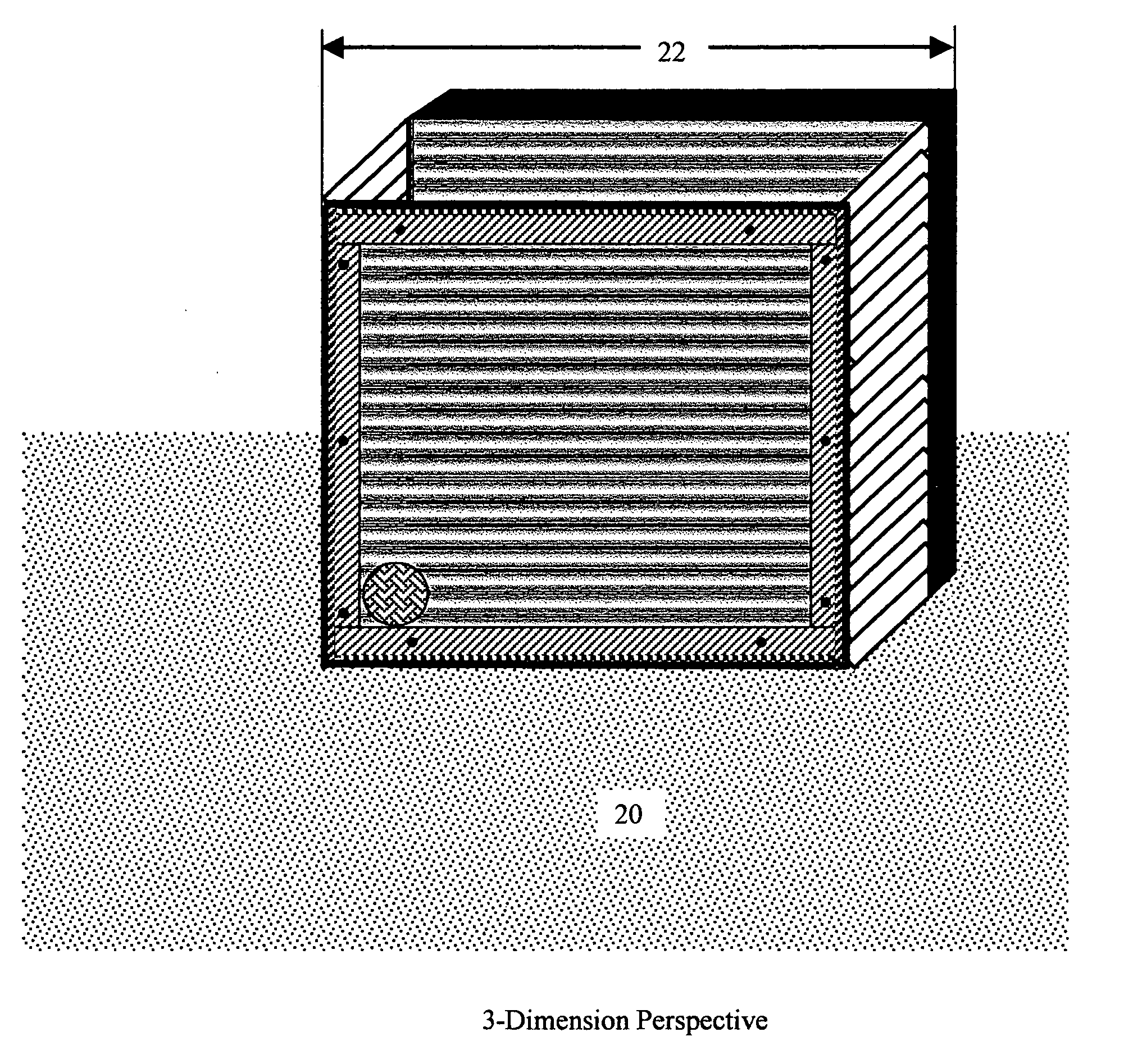

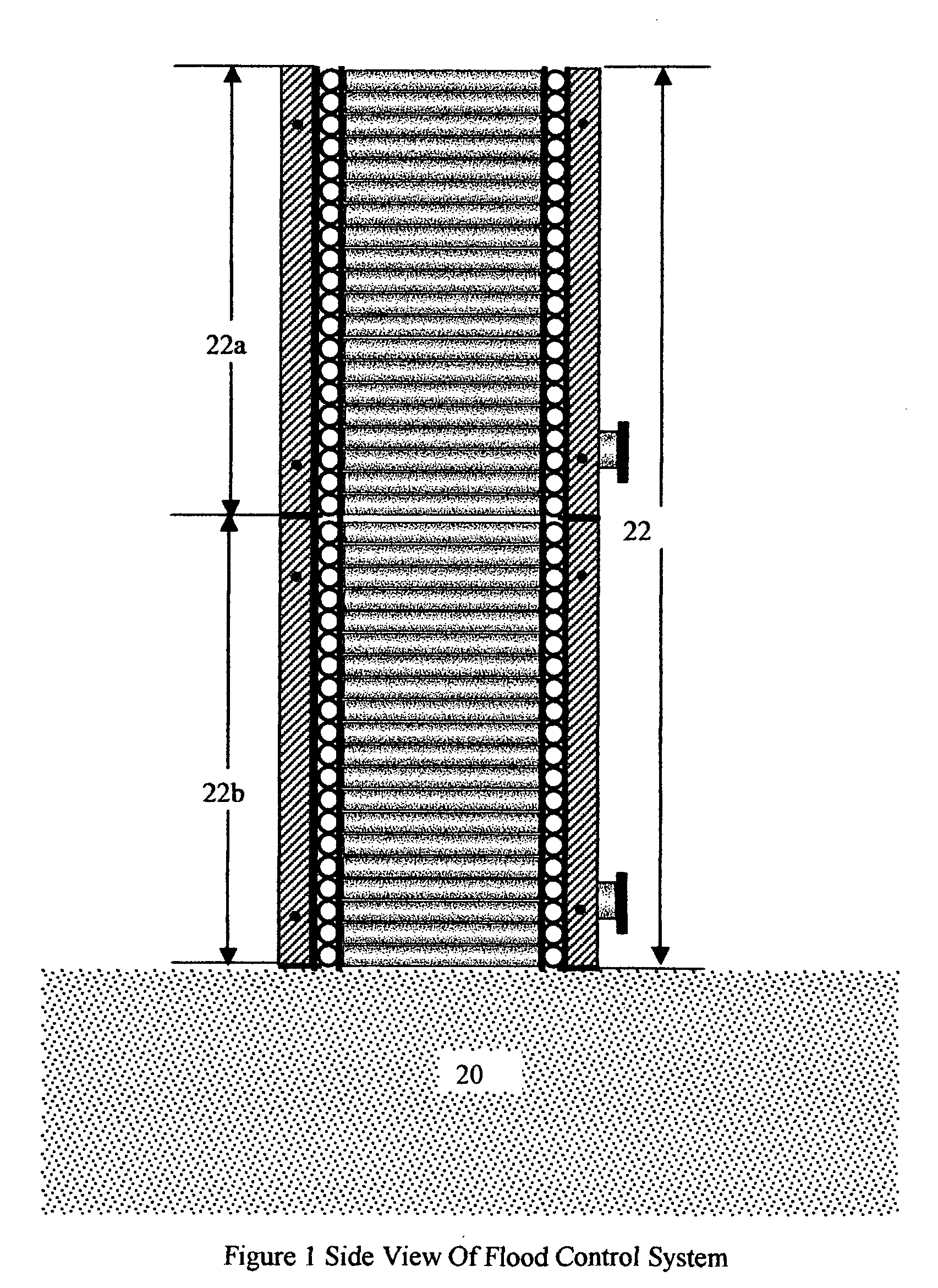

[0044] As mentioned above, the invention is preferably directed to flood control systems. Both methods and apparatus for flood control are within the scope of the invention. We wil now describe specific embodiments, examples and versions of the invention, for the purpose of enabling others skilled in the art to make and use our invention. It is understood, however, that the invention is not limited to these specific embodiments, examples and versions. Nor is the invention restricted to flood control as such, but may be used in other applications involving the forming of a barrier to prevent or restrict the flow of any liquid.

[0045] A person skilled in the art that has read this patent or seen the invention being used, described, or implemented will recognize many variations of the invention that might not be expressed here. Thus, it is the claims below that should be referred to for purposes of determining the scope of the invention, not only the literal elements therein, but also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com