Parquet block with woodwork joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

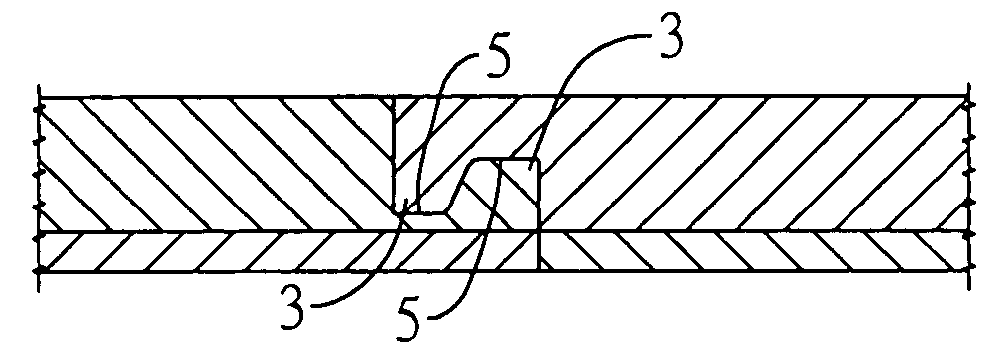

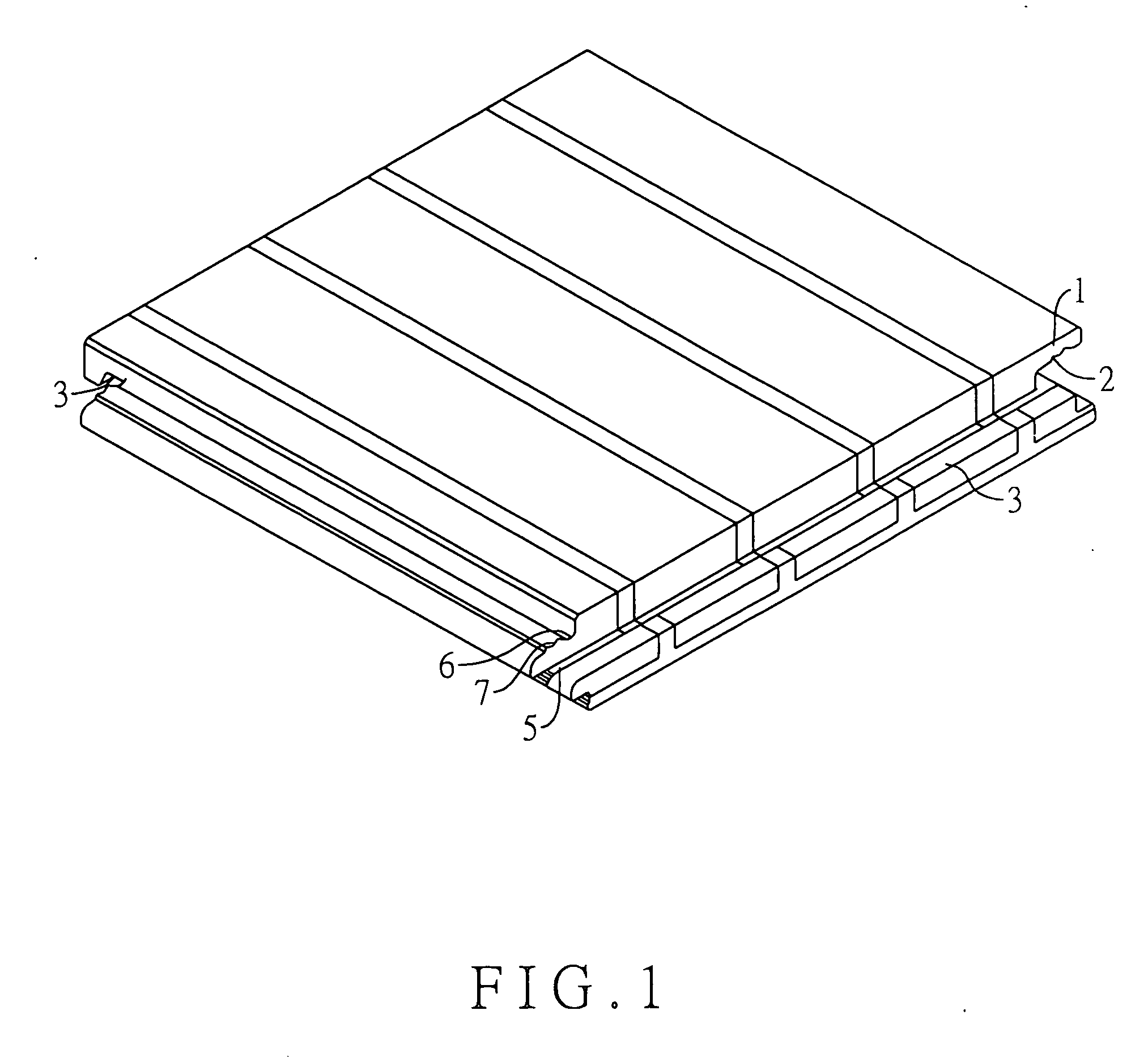

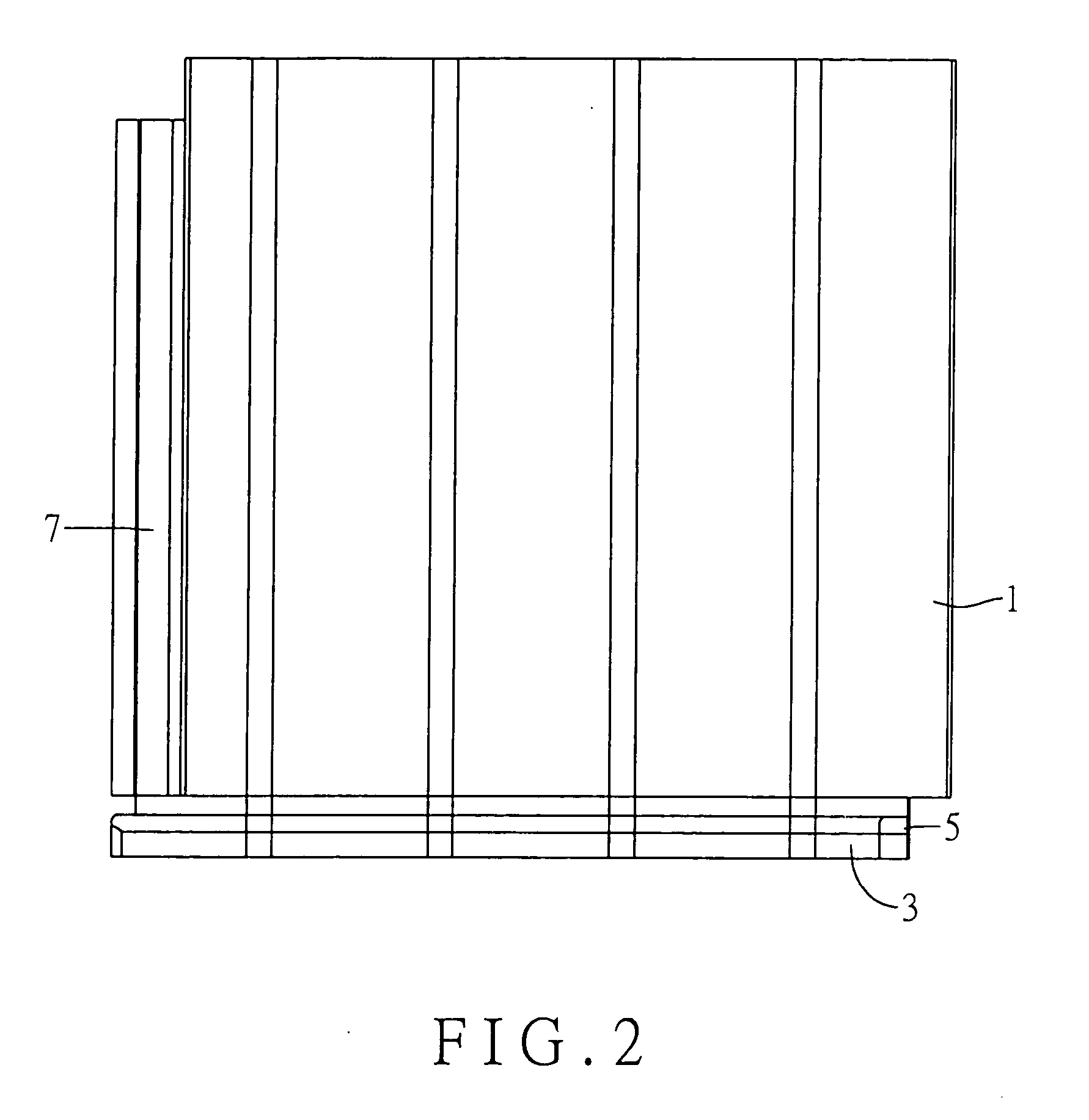

[0017] With reference to FIGS. 1 to 4, a parquet block in accordance with the present invention has woodwork joints to connect firmly to adjacent parquet blocks in each direction. The parquet block in accordance with the present invention has a front side (not numbered), a rear side (not numbered), a right side (not numbered), a left side (not numbered), an upper edge (not numbered), a lower edge (not numbered), a longitudinal tongue (1), a longitudinal notch (6), two transverse grooves (5) and two transverse tongues (3).

[0018] With further reference to FIG. 3, the longitudinal tongue (1) and the notch (6) are formed respectively on the right side and left side of the parquet block opposite to each other. The longitudinal tongue (1) has a short upper side (not numbered) and a long lower side (not numbered). The long lower side has a proximal edge (not numbered) and a longitudinal detent (2). The longitudinal detent (2) is formed at the proximal edge of the long lower side of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com