Sample tube

a technology of sample tube and sample tube, which is applied in the direction of instruments, process and machine control, laboratory glassware, etc., can solve the problems of exact same temperature cycle, error in sample temperature, and lengthen the total time needed to complete the amplification, so as to reduce the reagent cost and reduce the cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

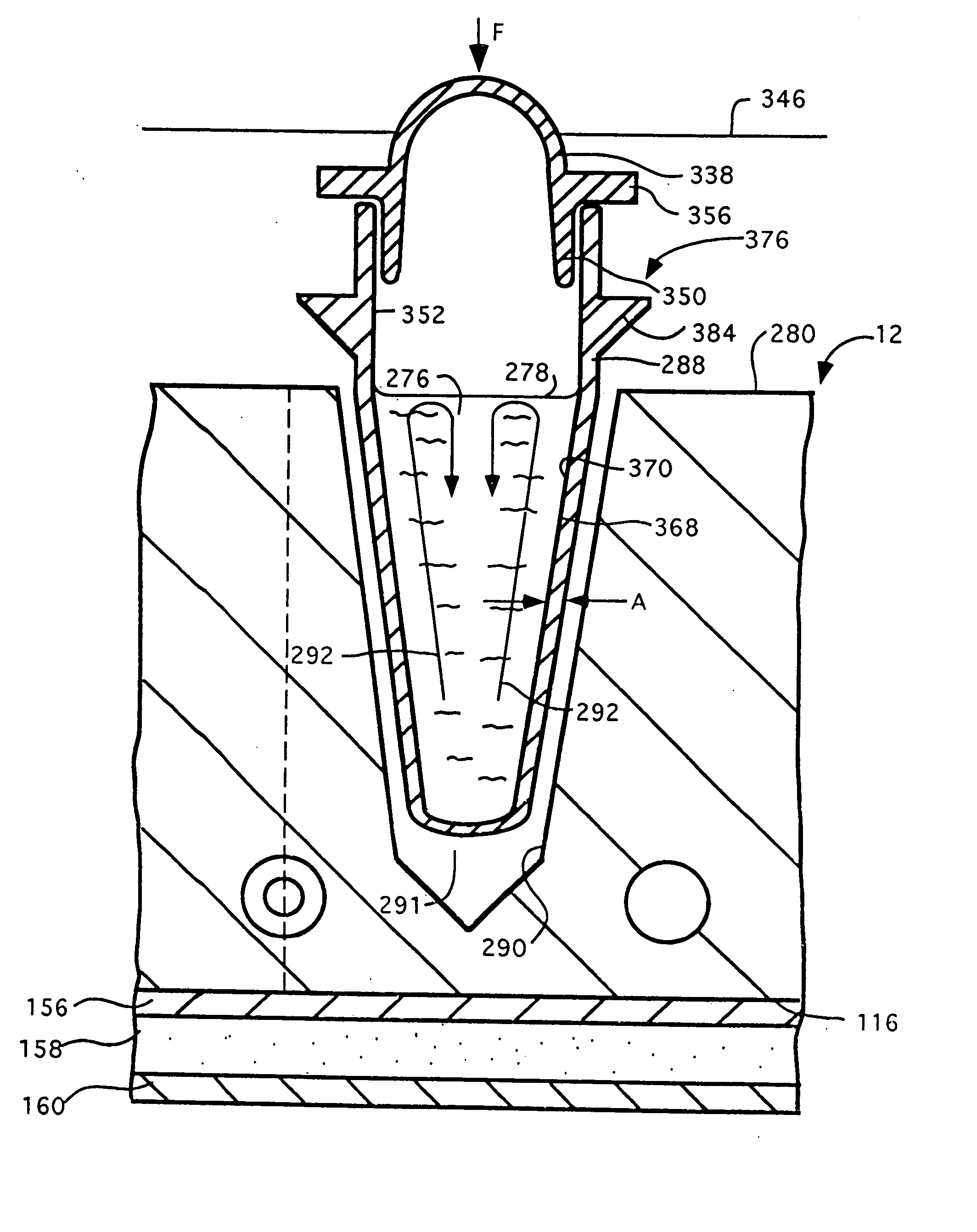

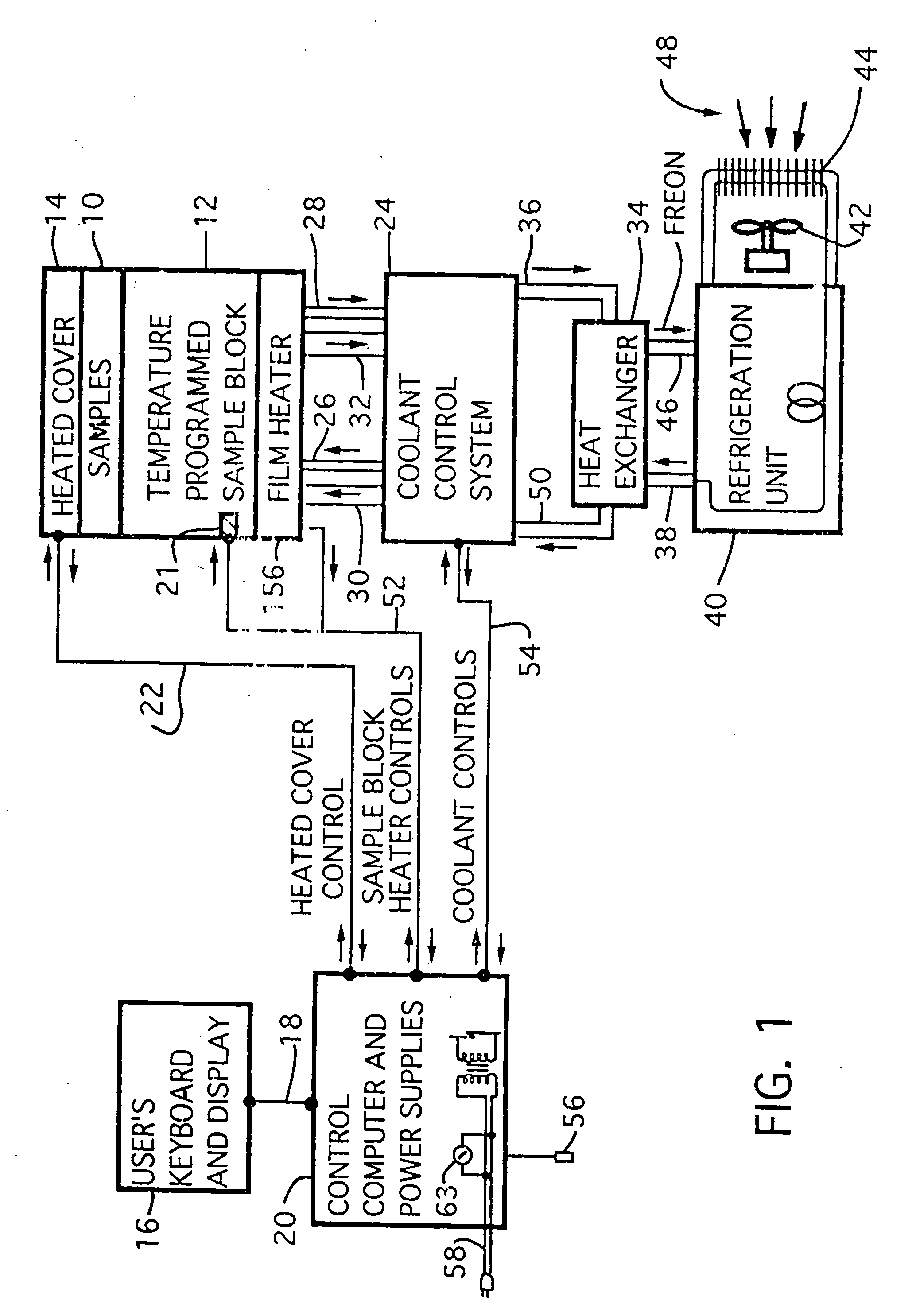

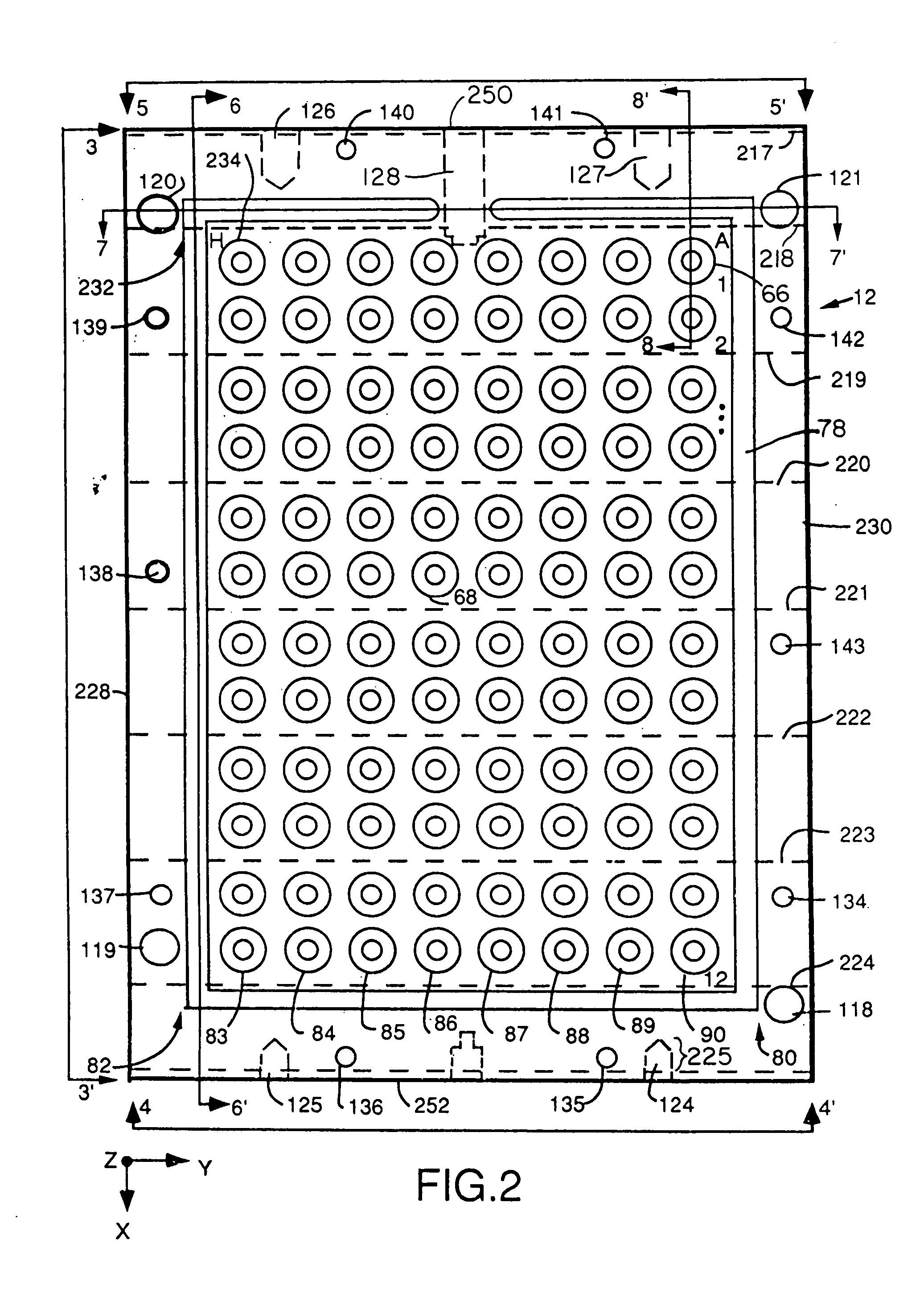

[0096] Referring to FIG. 1 there is shown a block diagram of the major system components of one embodiment of a computer directed instrument for performing PCR according to the teachings of the invention. Sample mixtures including the DNA or RNA to be amplified are placed in the temperature-programmed sample block 12 and are covered by heated cover 14.

[0097] A user supplies data defining time and temperature parameters of the desired PCR protocol via a terminal 16 including a keyboard and display. The keyboard and display are coupled via bus 18 to a control computer 20 (hereafter sometimes referred to as a central processing unit or CPU). This central processing unit 20 includes memory which stores the control program described below, the data defining the desired PCR protocol and certain calibration constants described below. The control program causes the CPU 20 to control temperature cycling of the sample block 12 and implements a user interface which provides certain displays t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com