Monitor for an optical fibre and multi-guide optical fibre circuits and methods of making them

a technology of optical fiber and optical fiber circuit, which is applied in the direction of transmission, photometry, structural/machine measurement, etc., can solve the problems of unsatisfactory methods, high loss and potential mechanical reliability problems, and enhance the possibility of corrupting signals, so as to achieve high yield and better control of exposed length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

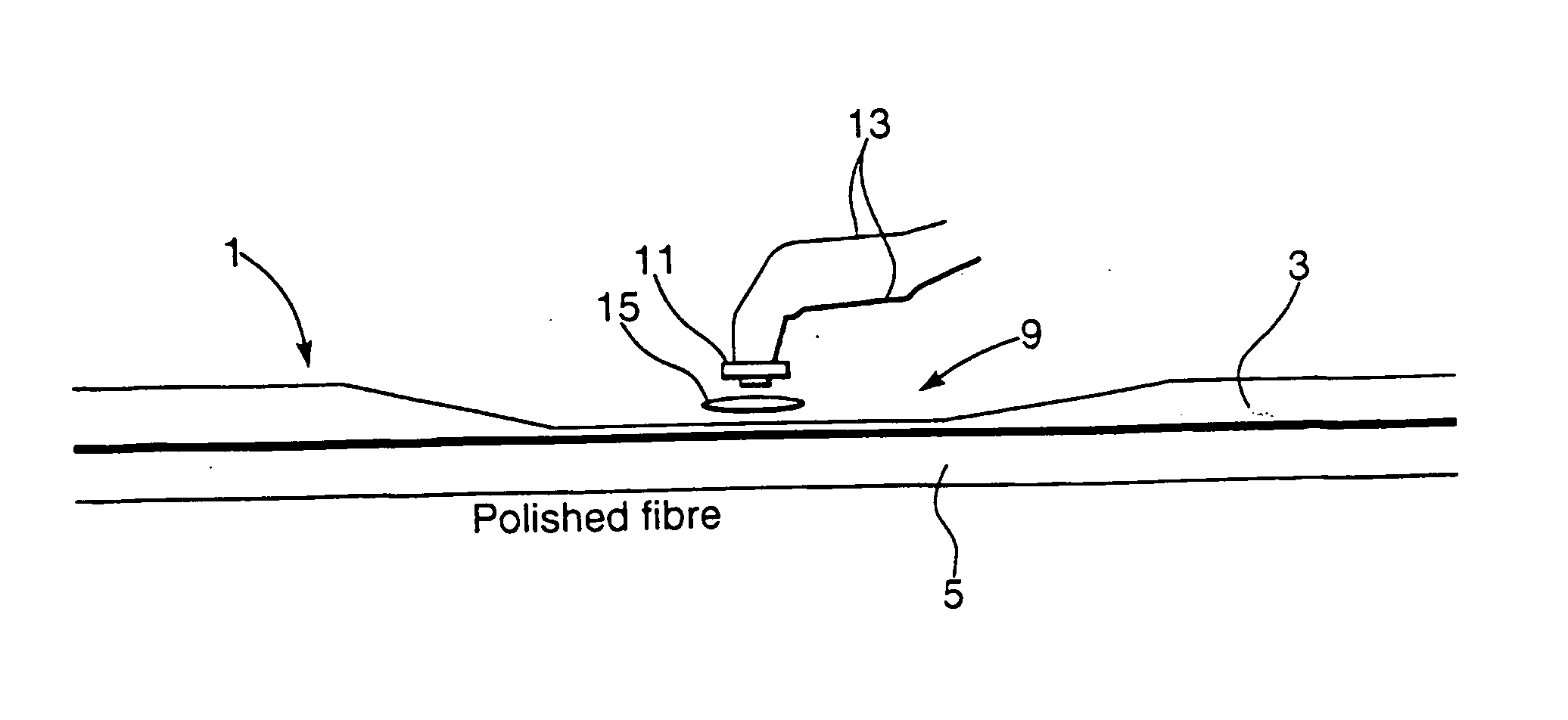

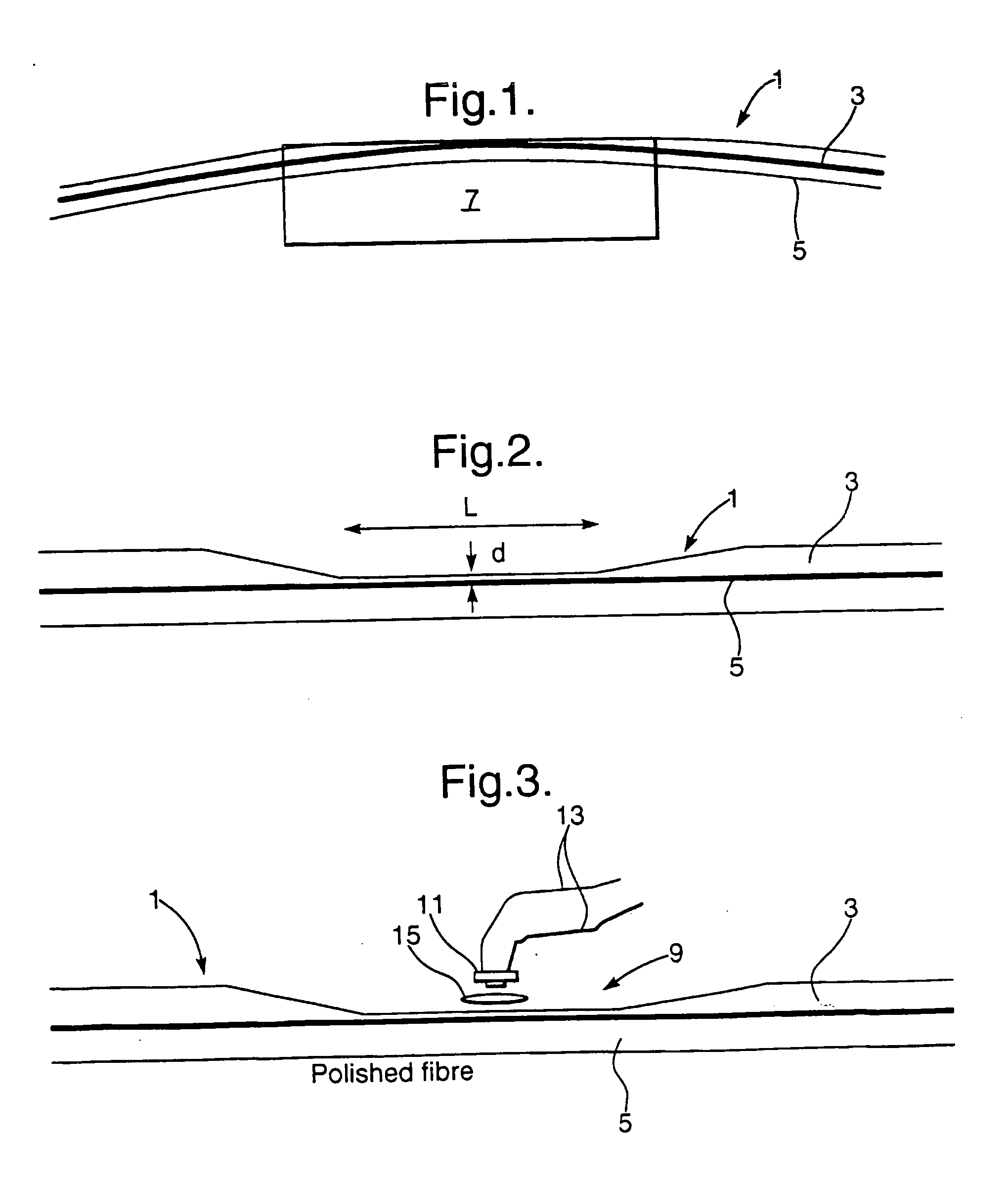

[0077] Referring firstly to FIG. 3, a first embodiment of the invention is shown. The figure shows an optical fibre 1 having a cladding 3 and core 5 with an access region 9 in which the cladding 3 is reduced by the method discussed above in relation to FIG. 2. An optical detector 11 provided with electronic output leads 13 is positioned adjacent to the optical fibre 1 in the region 9 so that it detects the evanescent field and converts this into an electrical signal on the leads 13. A lens 15 may be provided between the fibre 1 and the photo detector 11 if desired.

[0078] In practice, an holding mechanism (not shown) is used for holding the optical fibre with the exposed face vertical, such as a V-groove etched or machined into a suitable mounting material to hold the fibre firmly and allow it to be fixed permanently. The photo detector 11 is likewise mounted in the mounting material with its active area in close proximity to the exposed face of the access region 9 so as to mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com