Optical system with particular optical distortion

a technology of optical distortion and optical system, which is applied in the field of optical system with particular optical distortion, can solve the problems of difficult to achieve nearly ideal performance, difficult to adequately correct all aberrations over the entire field of view, and viewed on a monitor screen is also subject to tv distortion, etc., and achieves hardly noticeable distortion of an actual image, high optical performance, and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments 1 and 2

of the present invention will now be individually described with further reference to the drawings. In the following descriptions, references will be frequently made to a “lens element.” However, as set forth above, it is understood that lens elements described below are also lens components and may variously be replaced by lens components that include more than one lens element.

embodiment 1

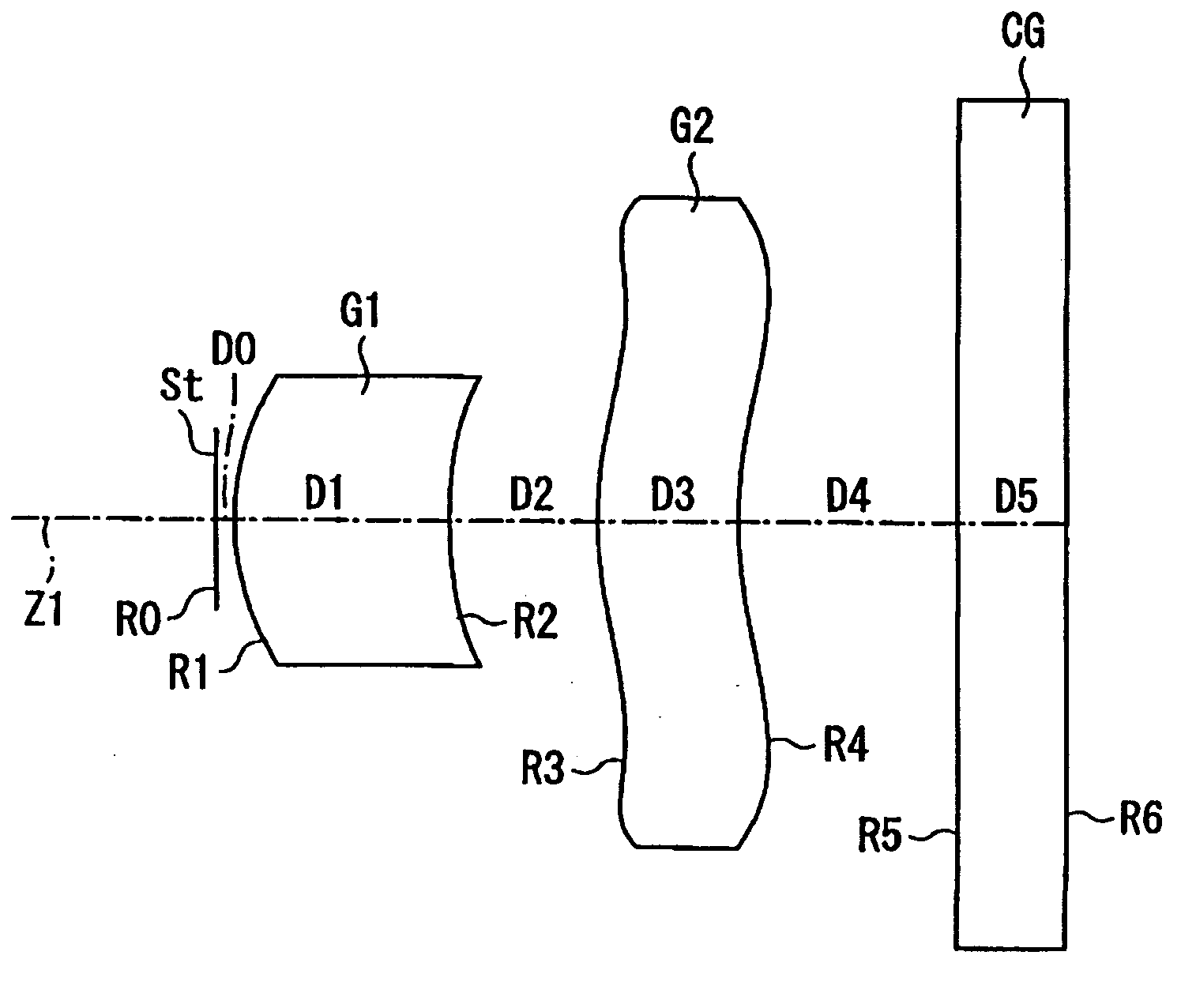

FIG. 1 shows Embodiment 1 of the present invention. Table 1 below lists the surface number #, in order from the object side, the radius of curvature R (in mm) of each surface near the optical axis, the on-axis surface spacing D (in mm), as well as the refractive index Nd and the Abbe number νd (both at the d-line of 587.6 nm) of each optical element for Embodiment 1. Listed in the bottom portion of Table 1 are the focal length f on the optical axis of the entire single focus lens, the f-number FNO, and the maximum field angle 2ω.

TABLE 1#RDNdνd0 (stop)∞0.101*1.46381.181.5061456.42*2.34640.823*2.09050.771.5061456.44*2.74661.185∞0.601.5168064.26∞

f = 3.94 mm FNO = 4.0 2ω = 60.7°

The surfaces with a* to the right of the surface number in Table 1 are aspheric lens surfaces, and the aspheric surface shapes are expressed by Equation (A) above.

Table 2 below lists the values of the constant K and the aspheric coefficients A3-A10 used in Equation (A) above for each of the aspheric lens sur...

embodiment 2

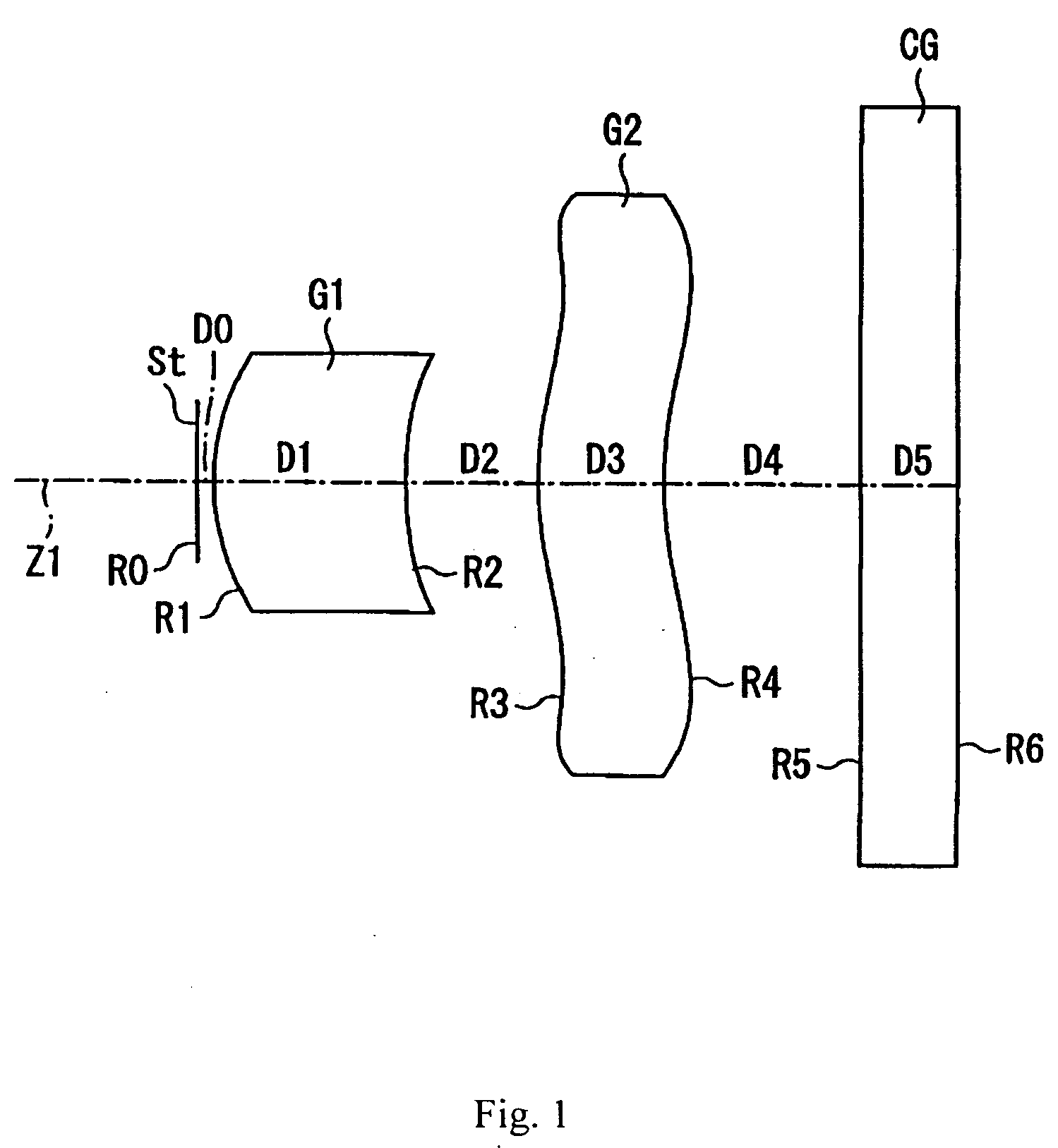

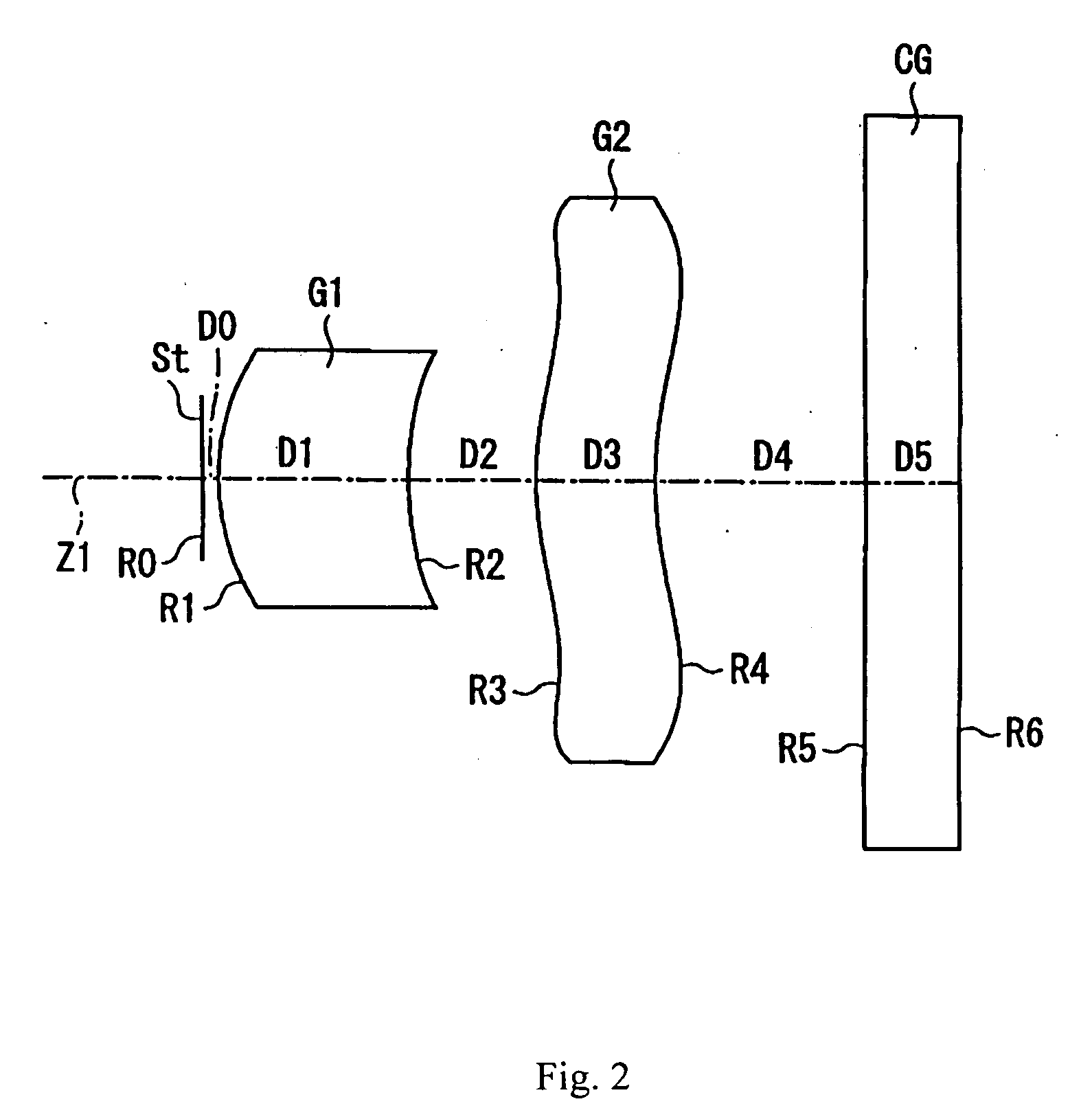

FIG. 2 shows Embodiment 2 of the present invention. Table 4 below lists the surface number #, in order from the object side, the radius of curvature R (in mm) of each surface near the optical axis, the on-axis surface spacing D (in mm), as well as the refractive index Nd and the Abbe number νd (both at the d-line of 587.6 nm) of each optical element for Embodiment 2. Listed in the bottom portion of Table 4 are the focal length f on the optical axis of the entire single focus lens, the f-number FNO, and the maximum field angle 2ω.

TABLE 4#RDNdνd0 (stop)∞0.101*1.45861.201.4902357.52*2.34800.813*2.09140.761.4902357.54*2.74891.305∞0.601.5168064.26∞

f = 4.08 mm FNO = 4.0 2ω = 58.9°

The surfaces with a*to the right of the surface number in Table 4 are aspheric lens surfaces, and the aspheric surface shapes are expressed by Equation (A) above.

Table 5 below lists the values of the constant K and the aspheric coefficients A3-A10 used in Equation (A) above for each of the aspheric lens surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com