Floating modular breakwater

a technology of modular breakwaters and breakwaters, which is applied in the field of floating modular breakwaters, can solve the problems of reducing the height of slow waves, requiring special equipment, and expensive equipment, and achieves the effect of establishing buoyancy and positioning the array in the water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

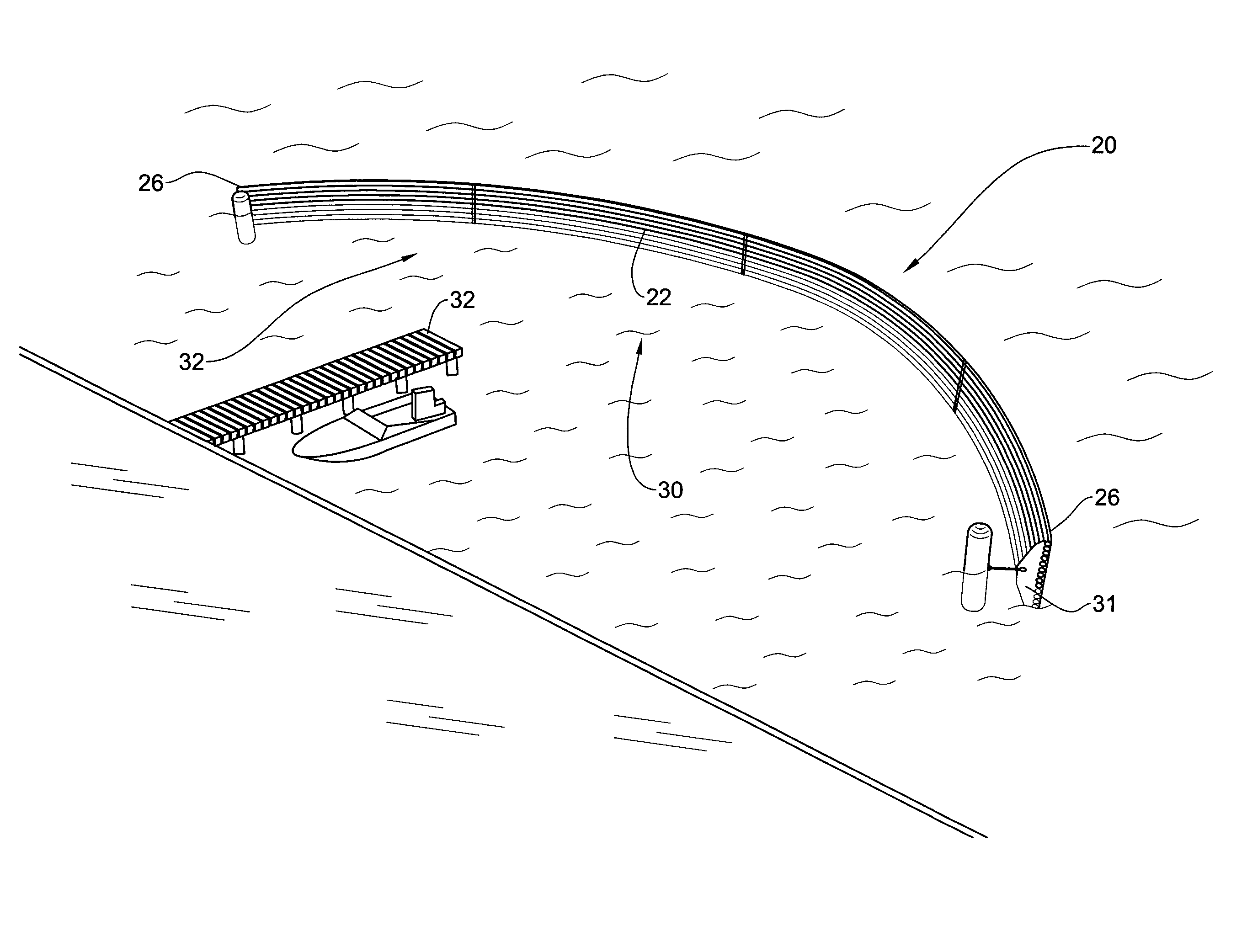

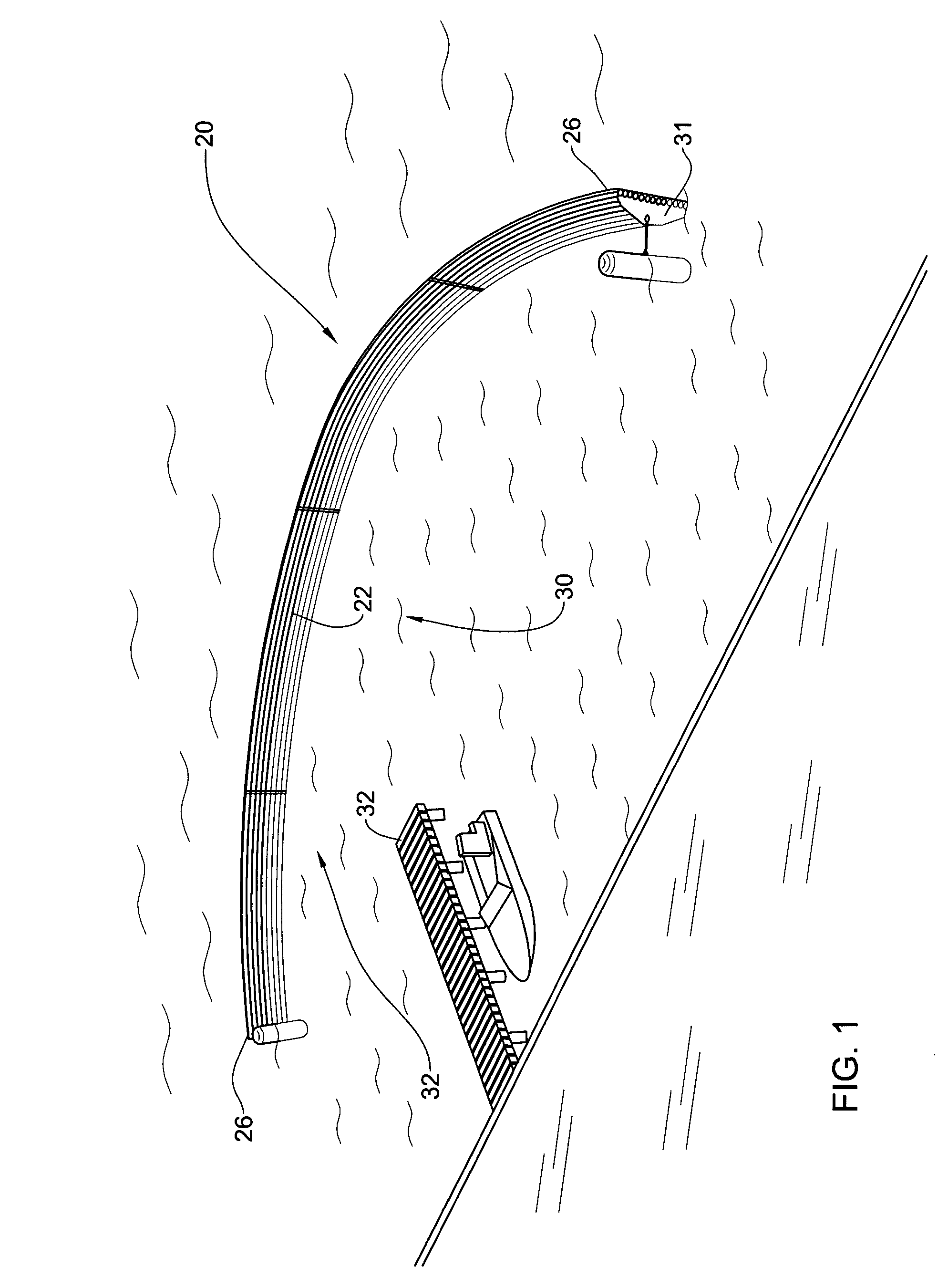

[0037]FIG. 1 is a bird's view of a breakwater in accordance with an embodiment of the present invention generally designated 20 comprising an array of rods 221o fixedly secured as will become apparent hereinafter and retained in the open waters at an arced / bowed configuration by means of bending force applied to respective ends 26 of the array thereby attenuating waves at the area designated 30, offering reduced sea state wave conditions around the deck 32.

[0038] With further attention directed also to FIG. 2, the breakwater 20 is seen in more detail and it is noticed that the array 22 comprises a plurality of longitudinal rods 26 parallelly retained at a substantially vertical / upright position, partially submersed in the water.

[0039] The rods are typically manufactured by an extrusion process and are made, for example of any combination of materials such as plastic, epoxy, polyester and may be reinforced by various fibers such as Kevlar®, glass or charcoal fibers, etc., as known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com