Method for monitoring plasma processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

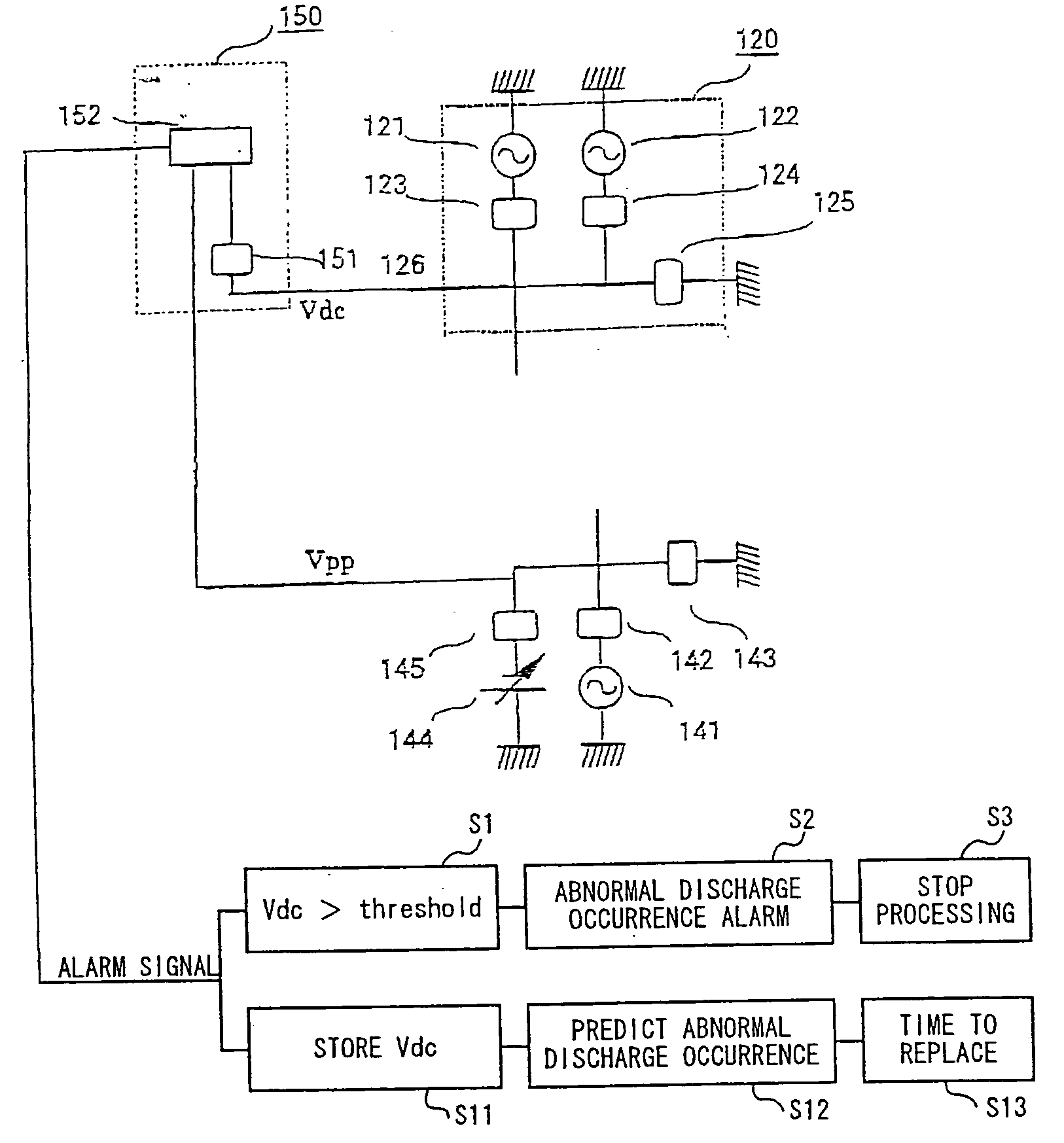

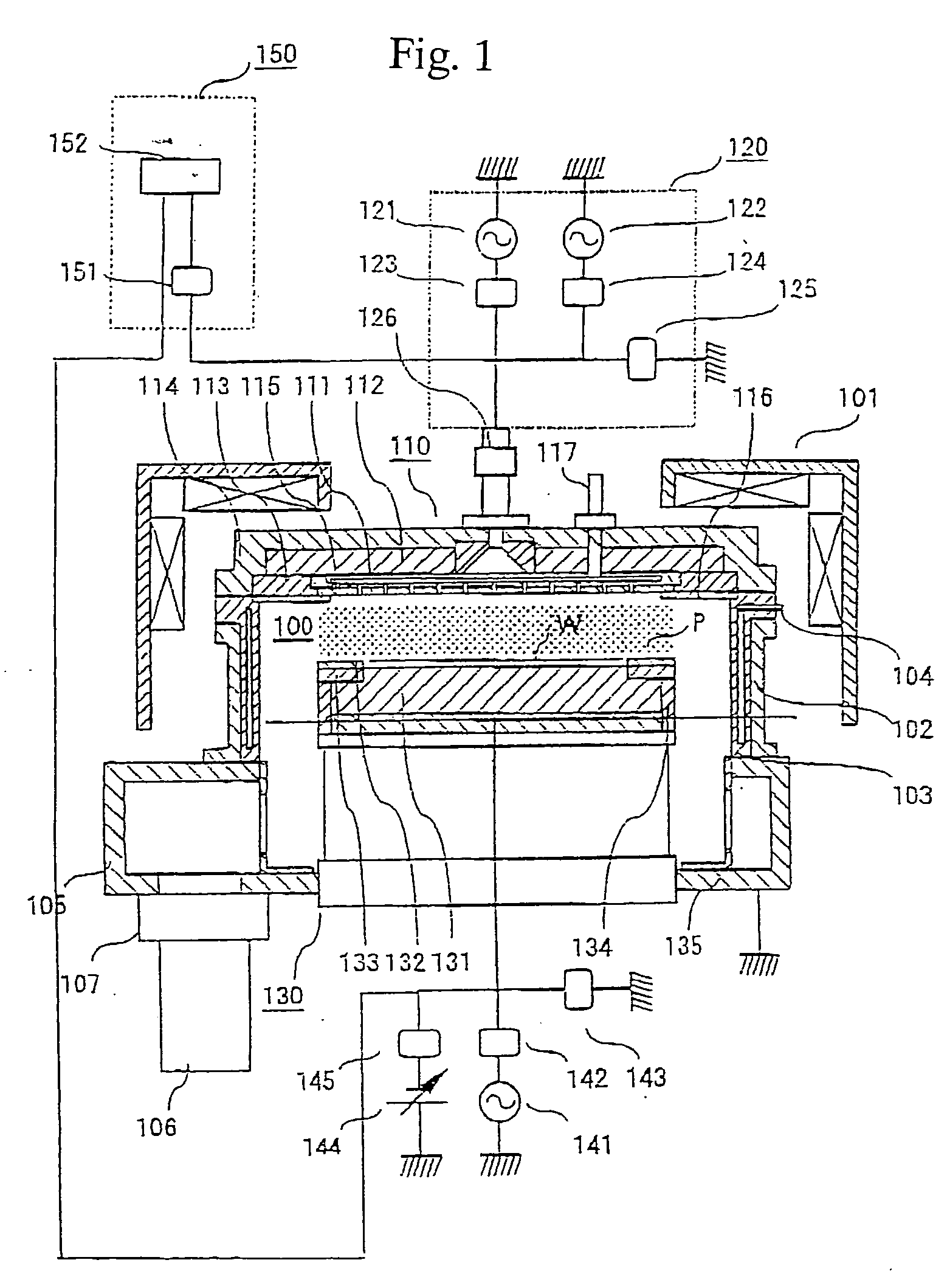

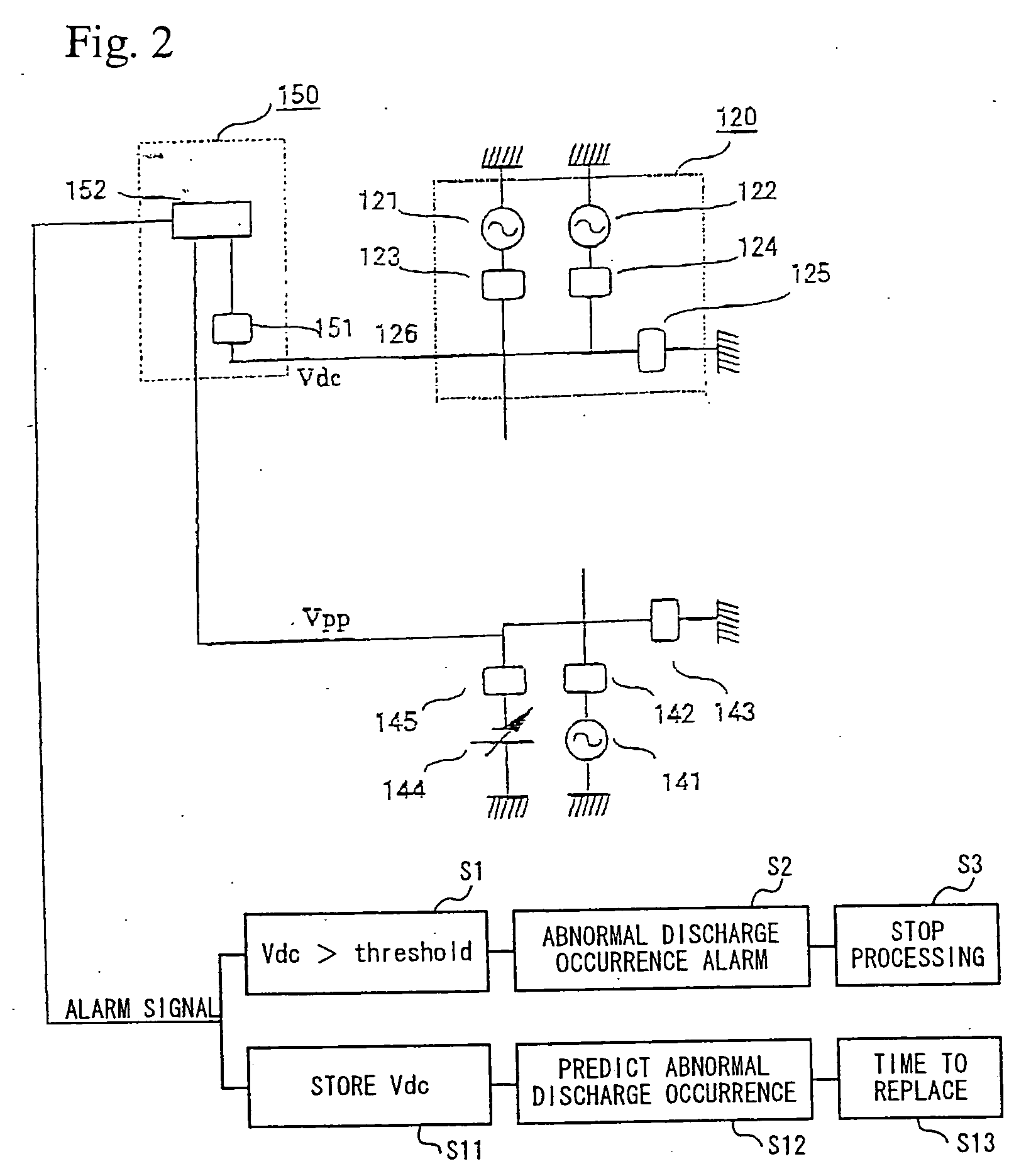

[0022] Now, a preferred embodiment of this invention will be described with reference to the accompanying drawings. FIG. 1 shows an apparatus for monitoring a plasma processing apparatus according to the embodiment of this invention, in which the plasma processing apparatus is a magnetic field UHF band electromagnetic wave radiation discharge type plasma etching apparatus. In this drawing, the plasma etching apparatus is schematically shown in section.

[0023] In FIG. 1, a process chamber 100 of the plasma processing apparatus is a vacuum container capable of attaining a degree of vacuum on the order of 10−5 Torr. An antenna 110 (upper electrode) for radiating electromagnetic waves is provided at the upper part of the process chamber, and a lower electrode 130 on which a sample W, such as a wafer, is to be mounted is provided at the lower part thereof. The antenna 110 and the lower electrode 130 are disposed in parallel facing each other. Magnetic field generator means 101, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bias potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com