Artificial masonry unit, a masonry wall, a kit and a method for forming a masonry wall

a technology of artificial masonry and masonry walls, which is applied in the field of masonry works and installations, can solve the problems of time-consuming, messy, unhandy and messy use of cement mixtures to temporarily retain masonry units, and achieve the effect of easy and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In the following description, similar features in the drawings have been given similar reference numerals and in order to lighten the figures, some elements are not referred to in some figures if they were already identified in a previous figure.

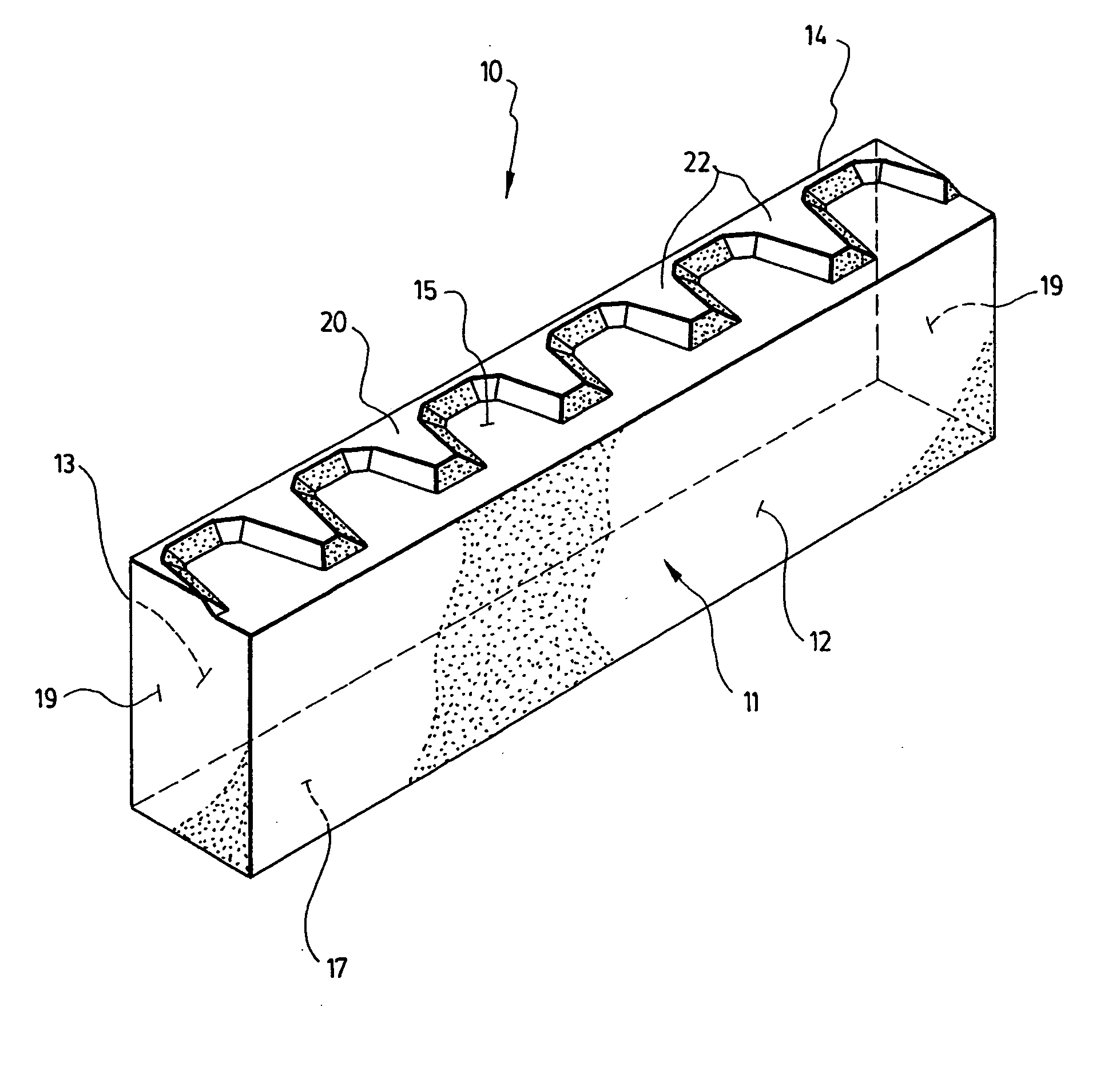

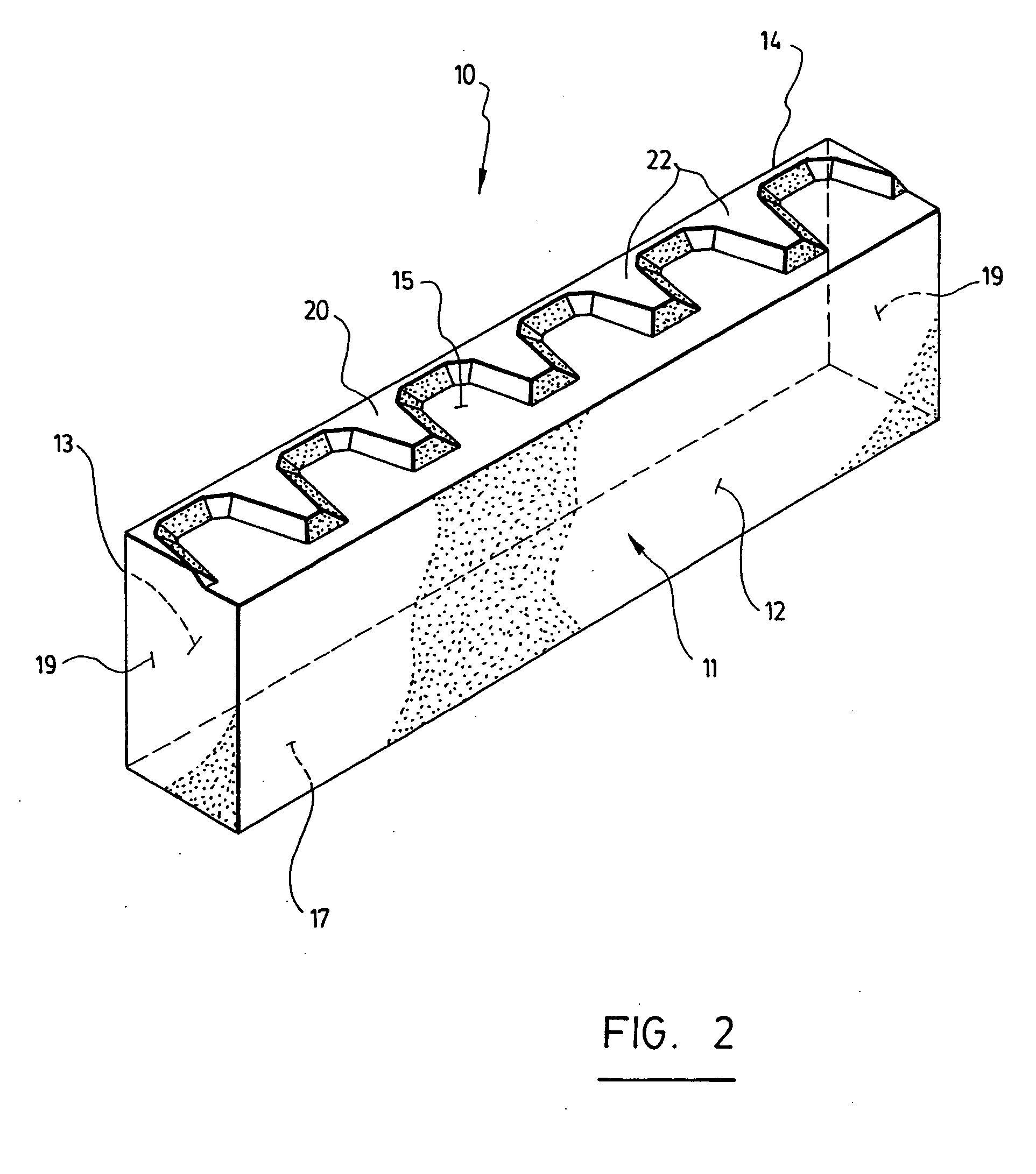

[0075] Referring to either one of FIGS. 2, 3 or 13, an artificial masonry unit (10) according to the invention comprises a body (11) with a front face (12), a back face (13) and a lateral face which divides into four edge faces including a top face (15), a bottom face (17), and two opposite side faces (19). The front face (12) is the face that is still visible to people once the artificial masonry unit (10) has been inserted in a masonry unit receiving depression (2) of a panel (1). The masonry unit (10) is characterized in that it further comprises a tooth projection (20) projecting from the lateral face next to and parallel to the back peripheral edge (14) for thrusting into the protruding rib (4) of the depression (2) when the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com