Heat exchanger device using a two-phase active fluid, and a method of manufacturing such a device

a heat exchanger and active fluid technology, applied in the direction of power cables, lighting and heating apparatus, laminated elements, etc., can solve the problems of large volume occupied by cylindrical rods themselves, large volume is occupied by cylindrical rods, and rigidity, and achieves low cost, facilitate interconnection ducts, and great freedom of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

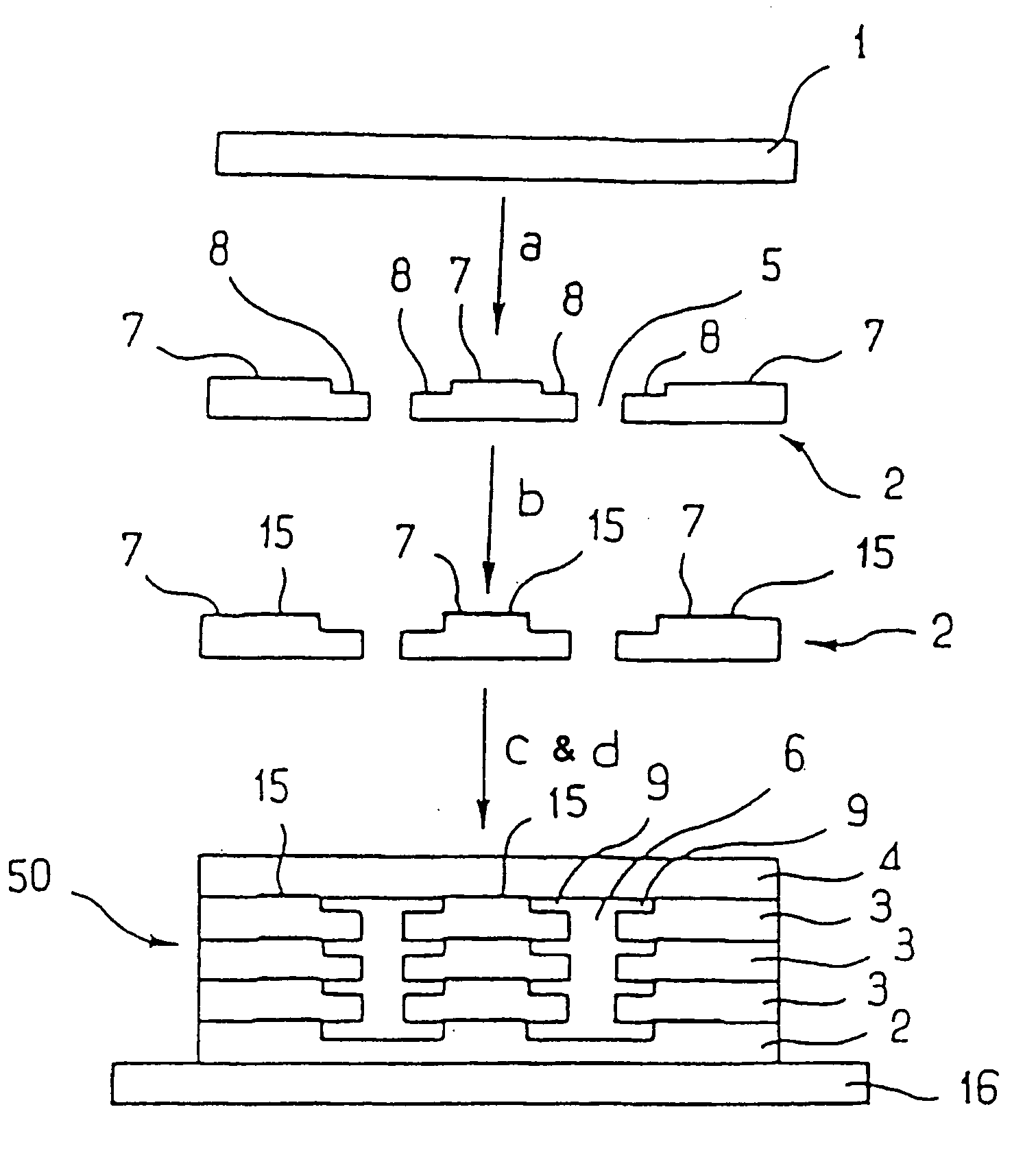

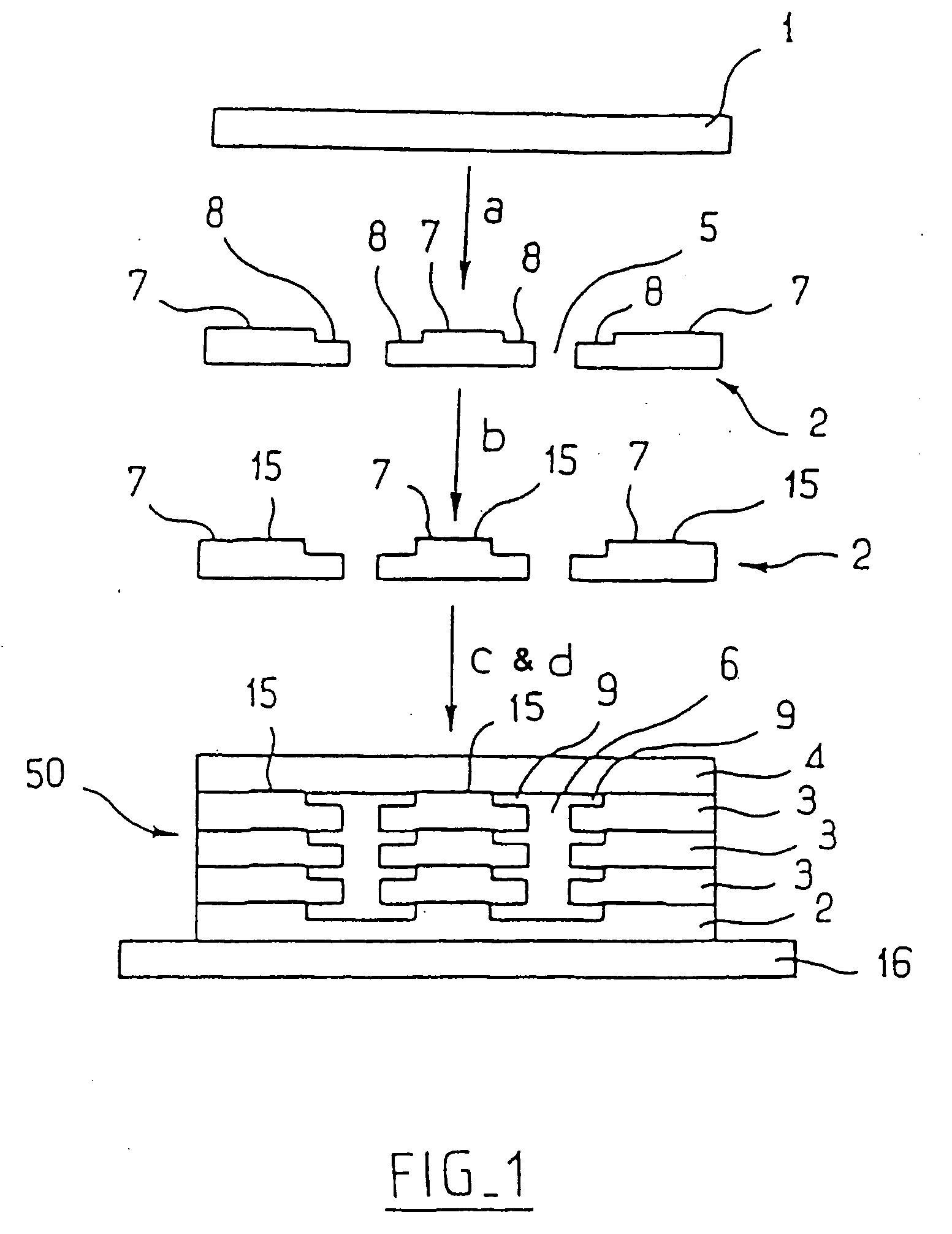

Preferably, but in non-limiting manner, a device of the invention can be made using the method illustrated in FIG. 1.

This method comprises a step a of etching grooves in blank sheets 1, a step b of localized deposition of a bonding material, a step c in which sheets previously prepared in steps a, and b are stacked, and an assembly step d for bonding together the set of sheets stacked in step c so as to form a heat pipe 50, for example.

A blank sheet 1 is constituted by a plate whose thickness preferably lies in the range 1.0 mm to 1 mm. By way of example, the material from which the sheets are made can be a metal. This metal can be copper, nickel, iron, aluminum, or indeed an alloy thereof, such as beryllium aluminum or stainless steel. The nature of the metal constituting the sheets depends on the active fluid used.

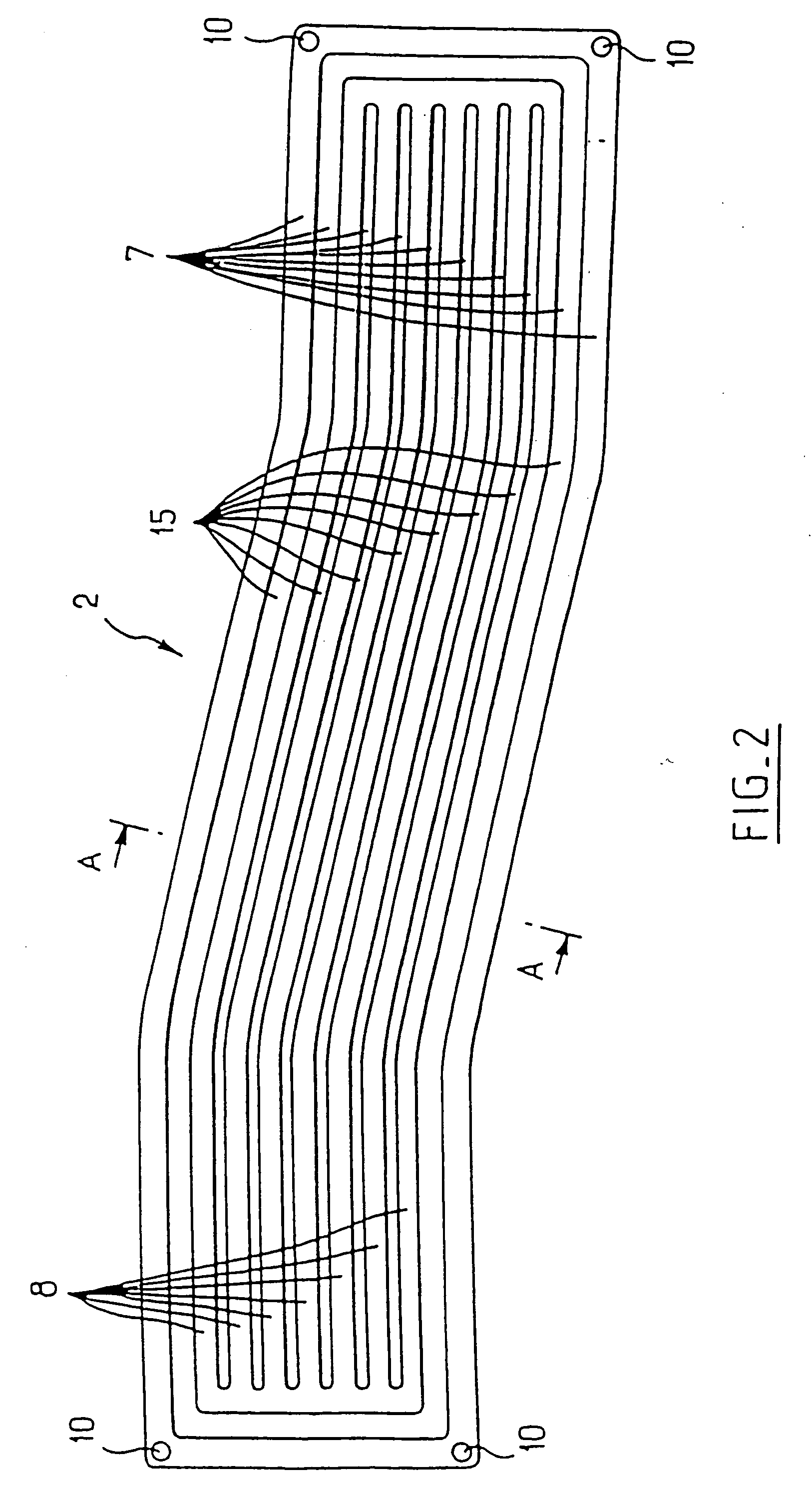

Several types of sheet are needed to make a heat pipe 50 of the invention. Starting from a blank sheet 1, it is possible to fabricate bottom sheets 2, intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com