Projectile for radially deploying sub-projectiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

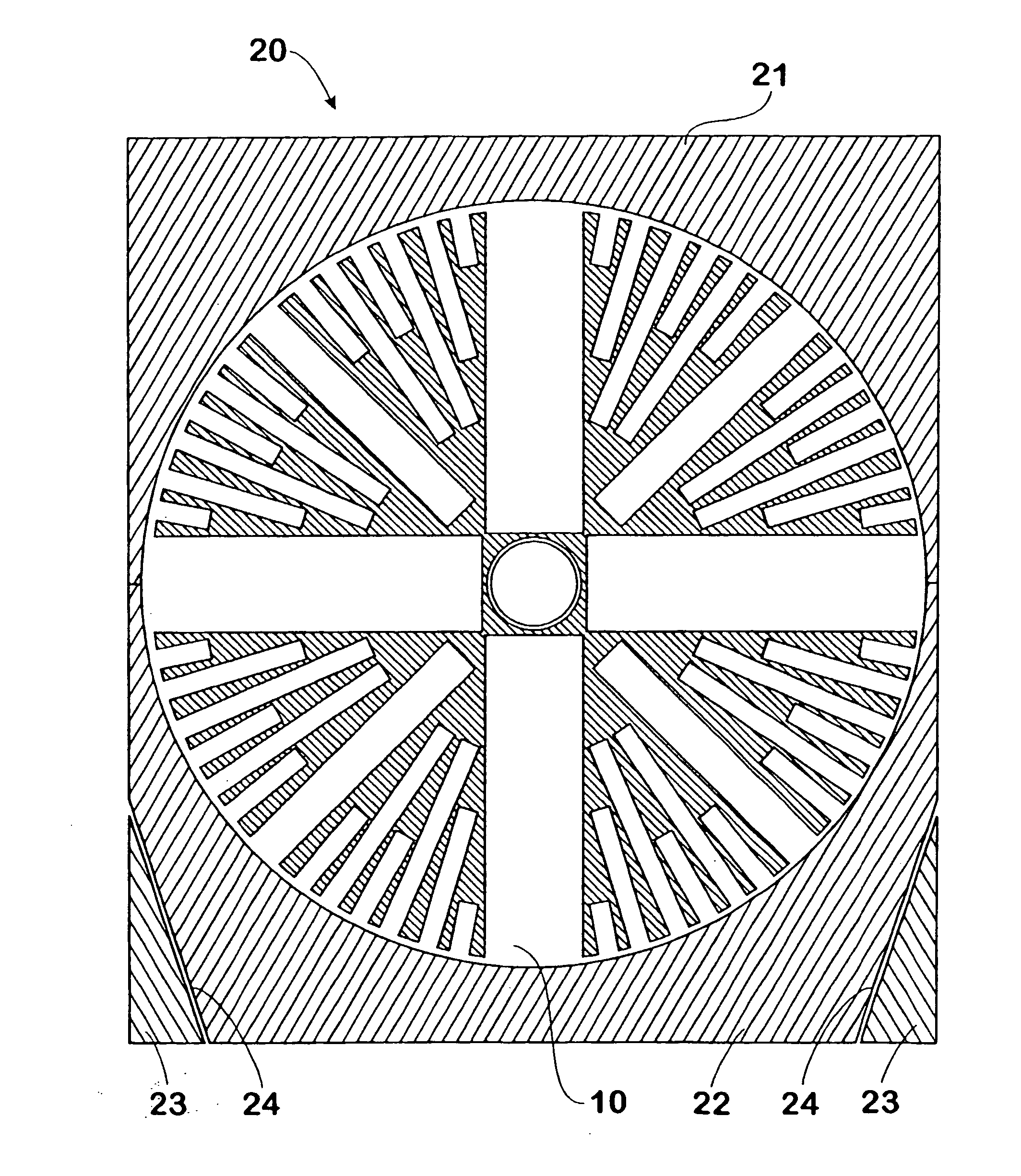

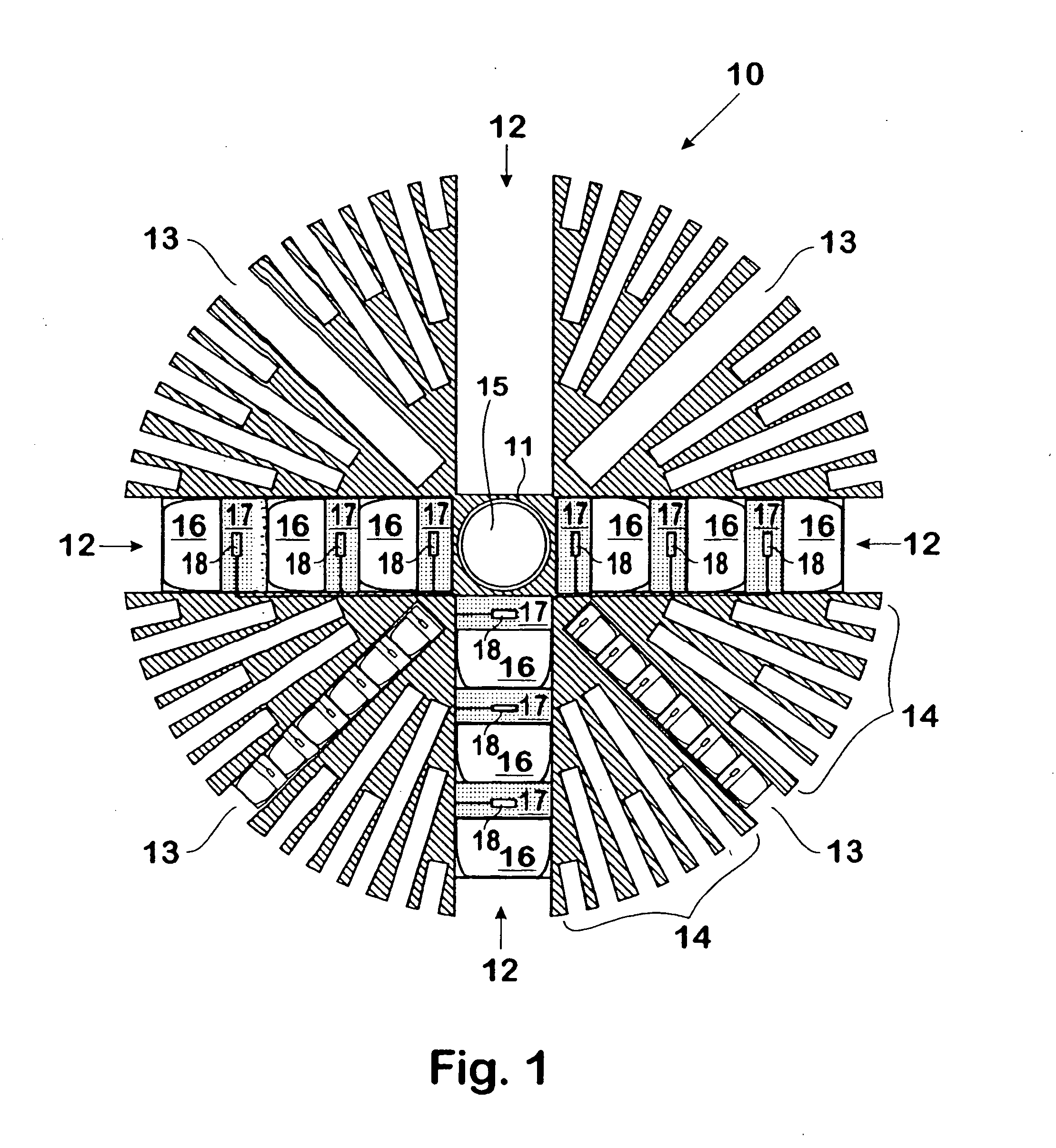

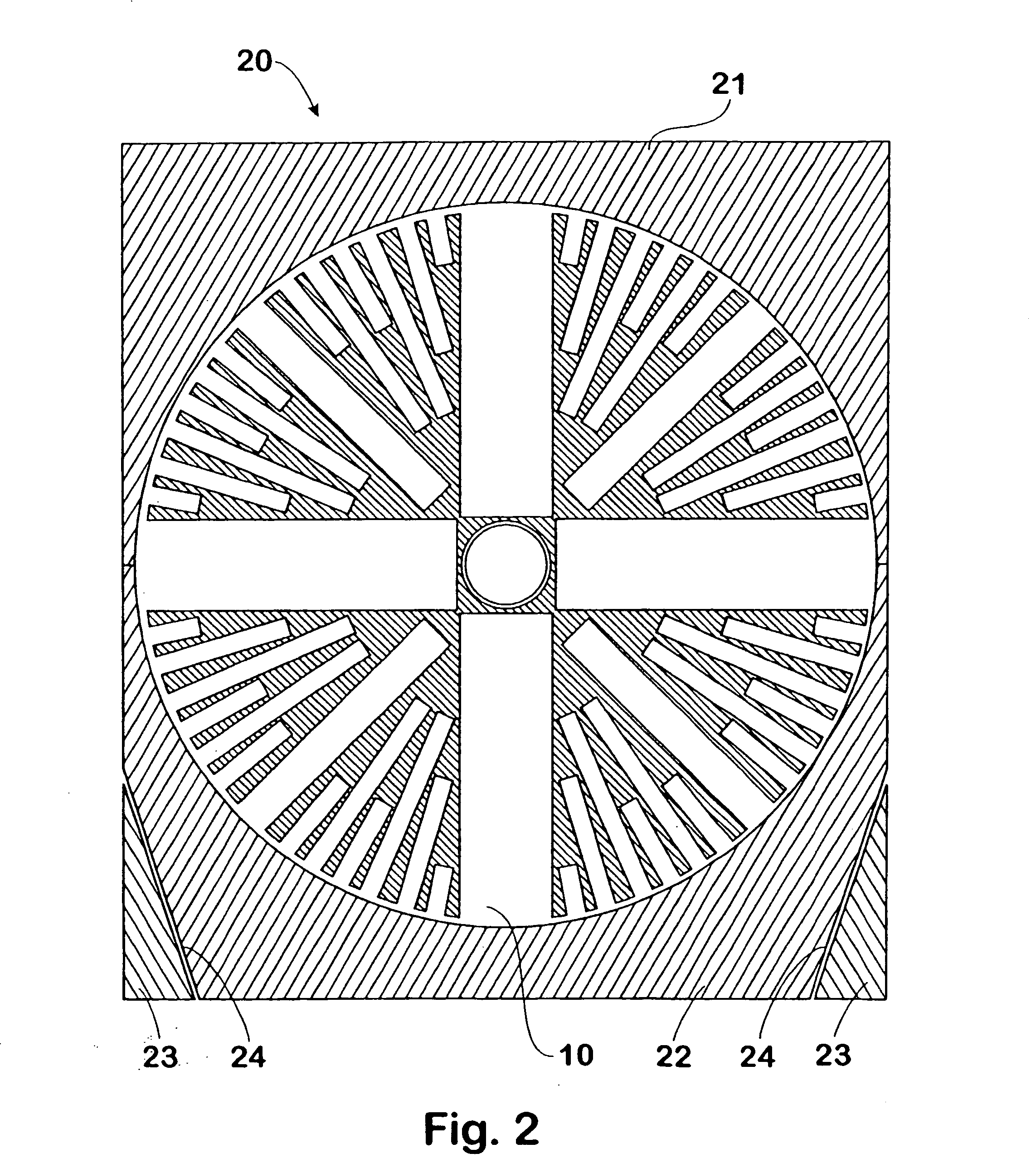

[0082] FIG. 1 shows a projectile 10 having six (6) large bore barrels 12 of a convenient calibre, although only four (4) are shown in this cross sectional representation. The remaining two (2) large bore barrels (extending perpendicularly to the page) are depicted at 11. The cross sectional representation also shows four (4) medium bore barrels 13 of medium calibre, and forty-eight (48) small bore barrels 14 of relatively small calibre. The large bore 12, medium bore 13 and small bore 14 barrels each contain a plurality of axially disposed sub-projectiles 16, as represented on the drawing. The sub-projectiles are associated with propellant charges 17 and ignition means 18, which ignition means may be sequentially fired under the control of an electronic controller 15. In some embodiments, the projectile 10 may also contain an explosive charge for terminal detonation.

[0083] The electronic controller 15, which is disposed in the centre of the projectile 10 behind the barrels 11, 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com