Dispenser for granular or powdered food products, for example grated cheese and similar loose food products , and corresponding manufacturing process

a technology for food products and dispensers, which is applied in the direction of containers, closure stoppers, packaged goods, etc., can solve the problems of not being able to attract commercial interest, the container is large in cost, and cannot be dispensed through the bottom opening any more,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

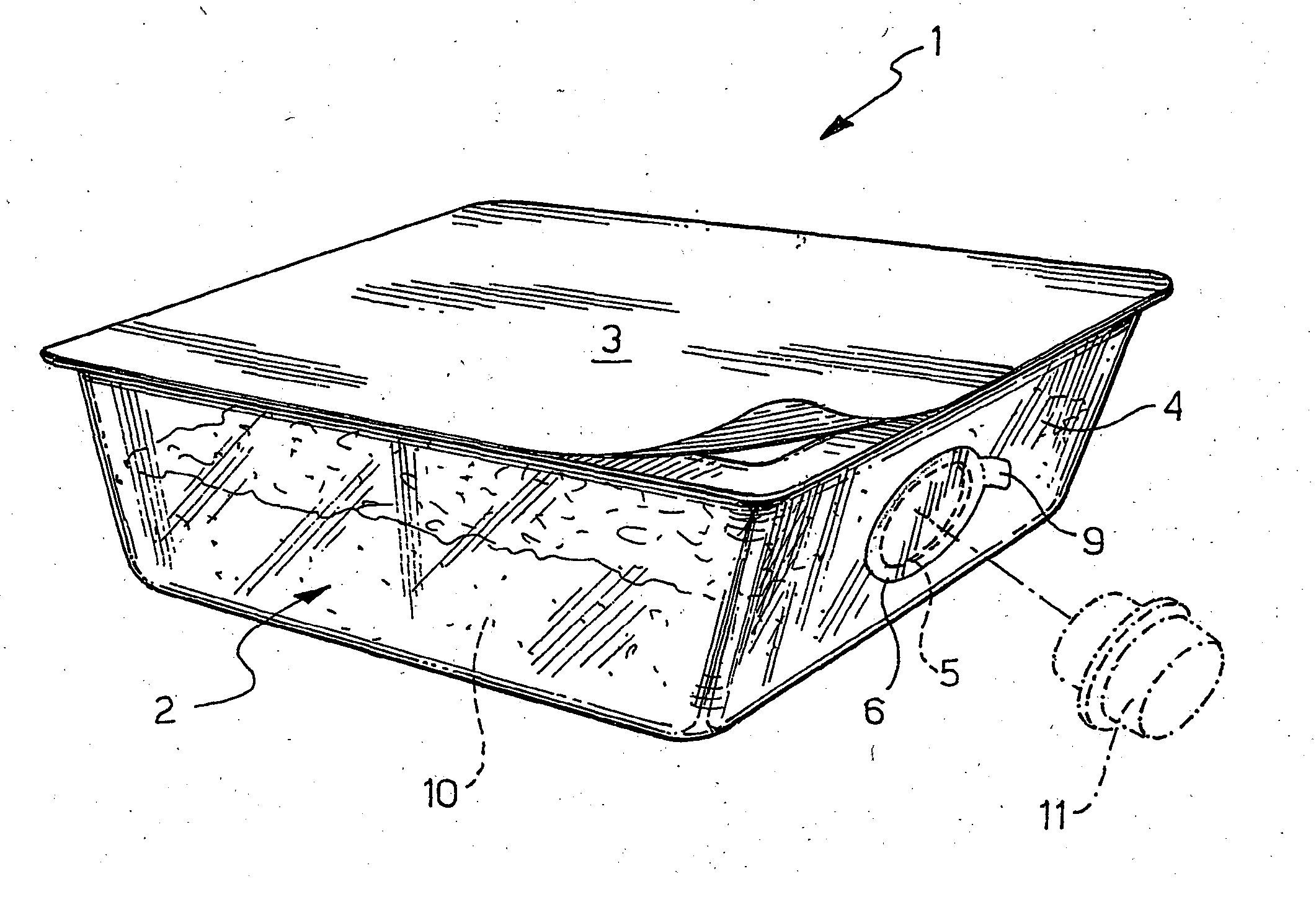

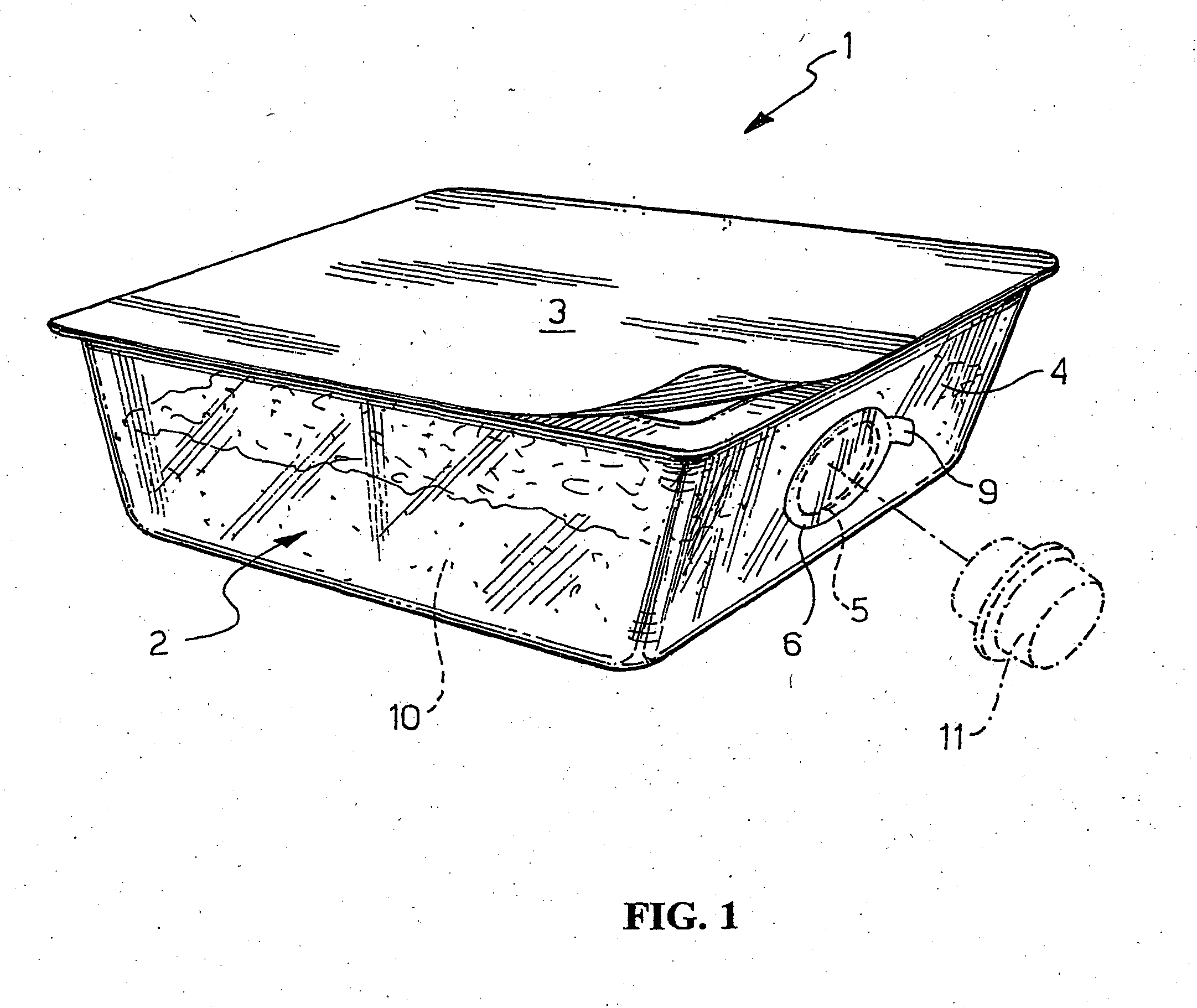

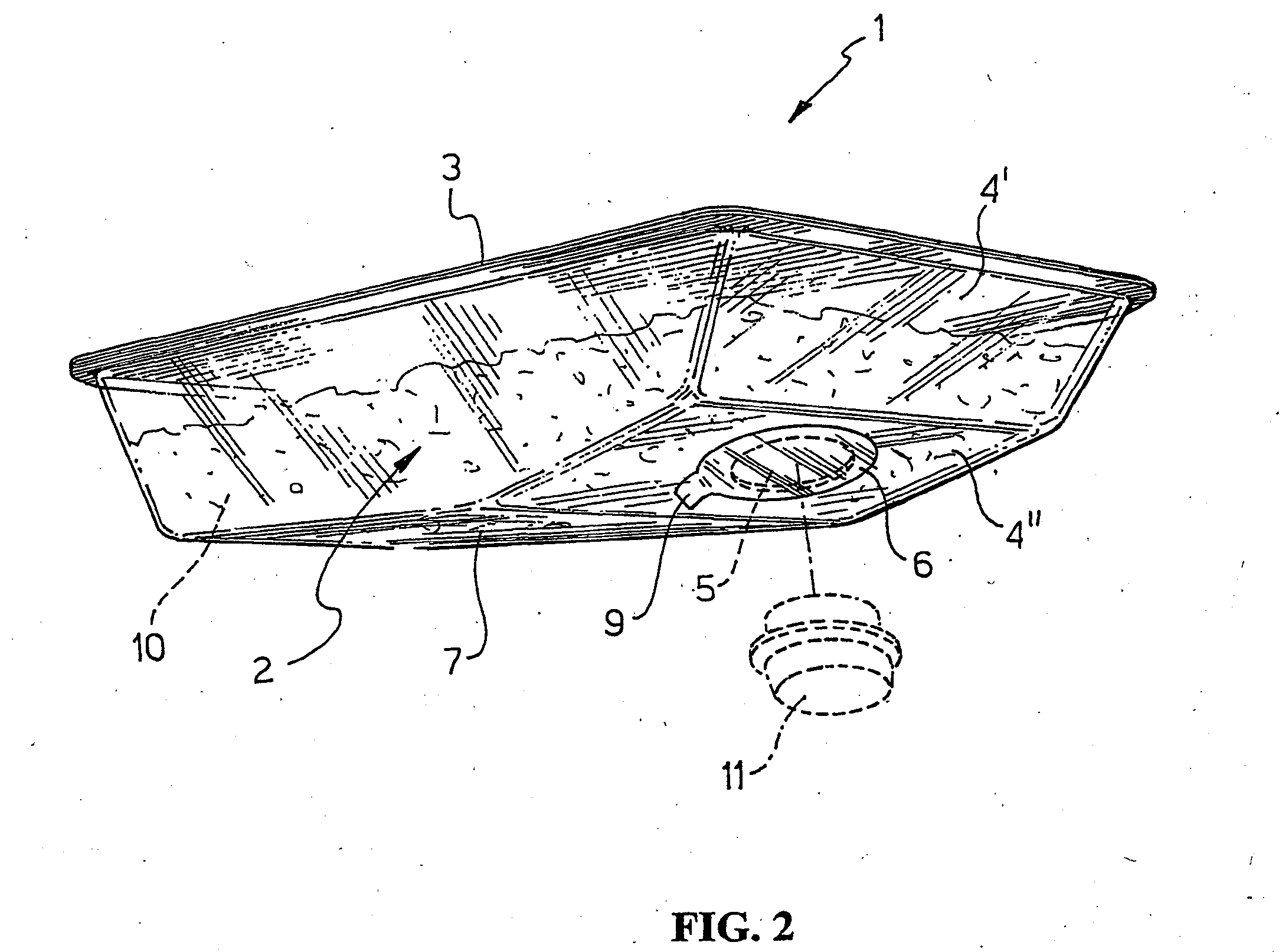

[0030] With reference to the drawing views, a dispenser of granular or powdered food products, such as grated cheese or the like loose food products, according to this invention, is shown at 1 in schematic form and is adapted to conserve food products durably therein.

[0031] The dispenser 1 also serves as a container for the food product, a granular type of food product being generally shown at 10. This dispenser is also suitable for long-term storage of the products therein in the cooled counters of food stores.

[0032] Advantageously in this invention, the dispenser 1 comprises a tray-type container 2, which is closed at the top with a sheet cover 3 of a synthetic material heat-sealed all around the tray rim.

[0033] The container 2 is preferably made of a thermoformed synthetic plastics material for food applications. The product 10 is contained and preserved in the dispenser 1 under an inert atmosphere, preferably nitrogen gas.

[0034] In a preferred embodiment, the container 2 is ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com