Insulated-gate field-effect transistor, method of fabricating same, and semiconductor device employing same

a field-effect transistor and insulating gate technology, applied in the direction of transistors, semiconductor devices, electrical devices, etc., can solve the problems of p-type transistors being more susceptible to punching, difficult to achieve high performance through downsizing, and inability to sufficiently reduce the thickness of the layer upon the insulator layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 1

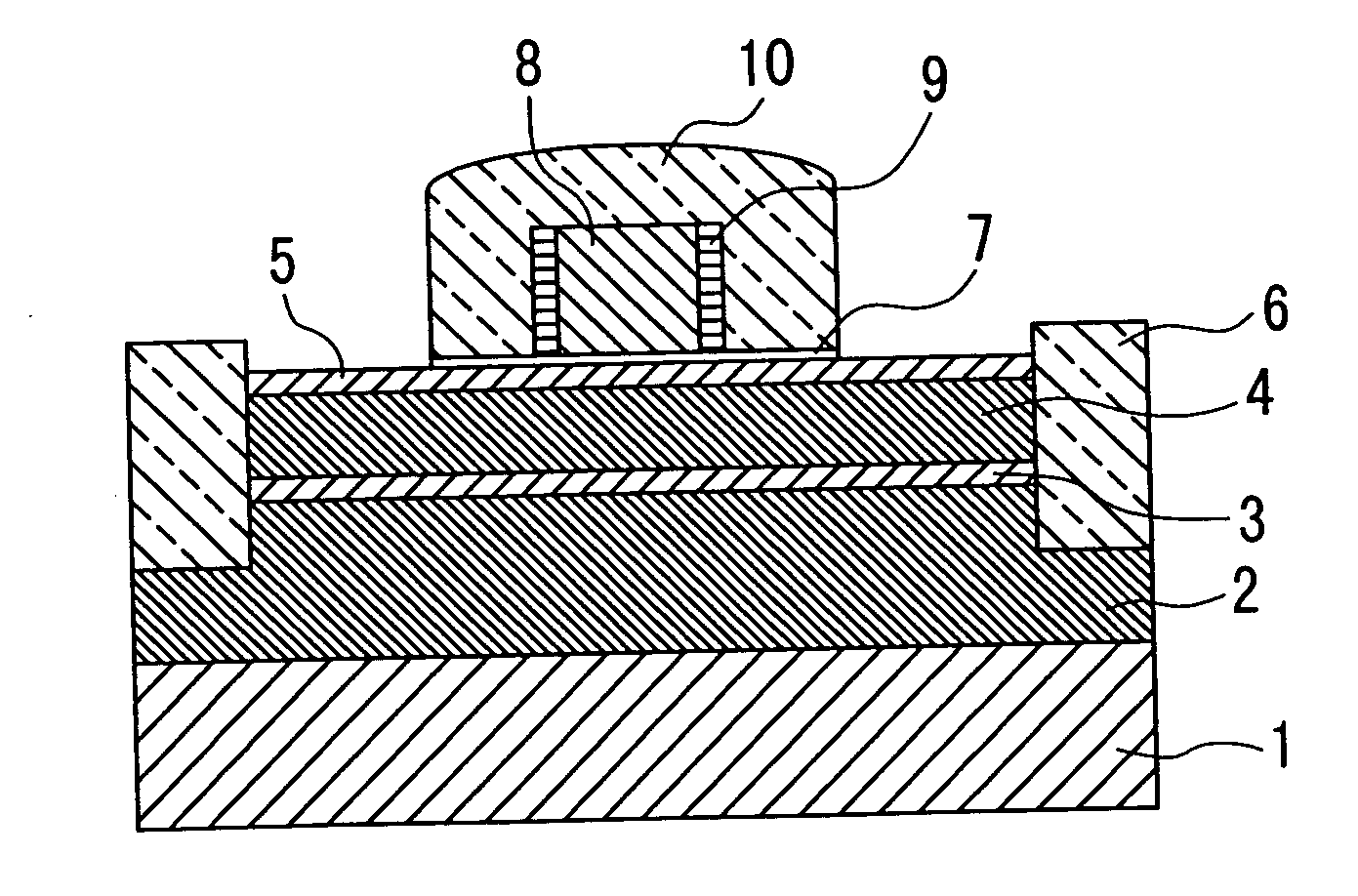

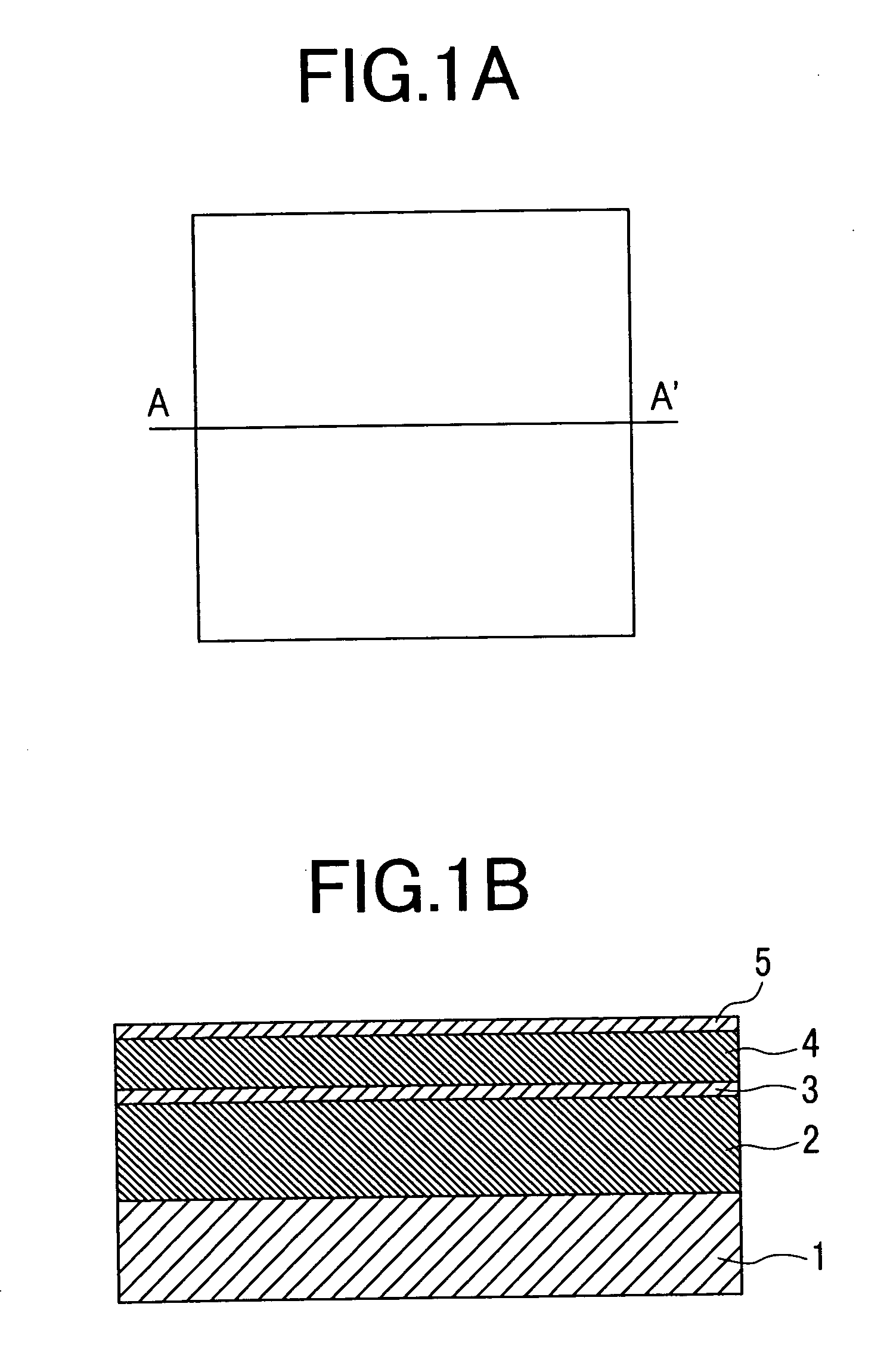

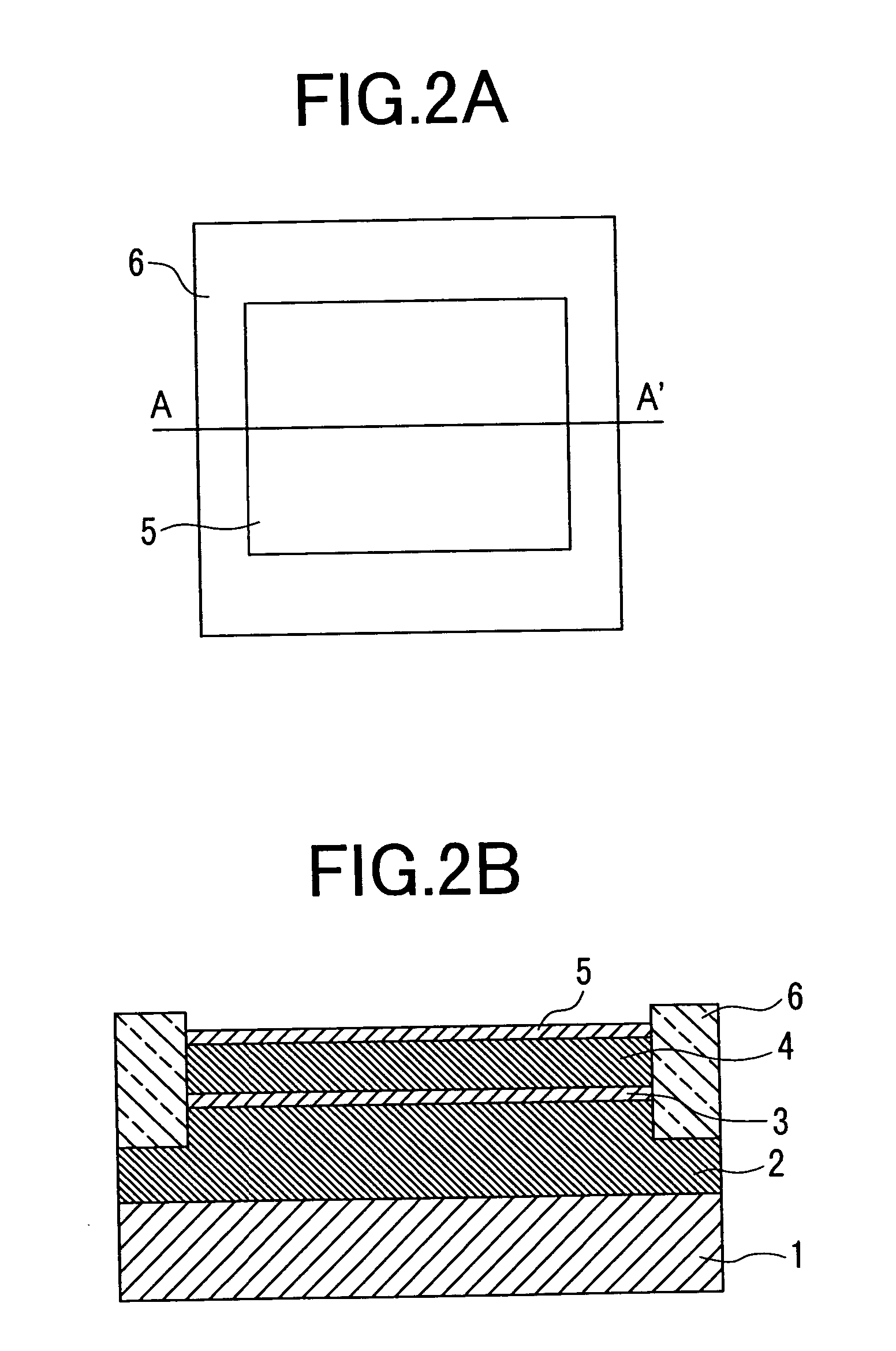

[0101] Embodiment 1

[0102] Embodiment 1 is concerned with a method of fabricating an insulated-gate field-effect transistor for which a novel planar configuration is devised for removal of a portion of a silicon germanium layer, directly underneath a strained silicon layer.

[0103] FIGS. 1 through 9 are schematic illustrations showing a semiconductor device in the order of steps of the method of fabricating the same according to the present embodiment. FIG. 1 shows a strained silicon / strain-relaxed silicon germanium substrate by way of example. FIG. 1A is a plan view of the substrate and FIG. 1B is a sectional view taken on line A-A' in FIG. 1A. Suffix "A" of FIGS. 1 through 9, respectively, indicates a plan view of a base body, suffix "B" a sectional view taken on line A-A' in "A" of the respective figures, and suffix "C" a sectional view taken on line B-B' in "A" of the respective figures. Only FIGS. 5 through 9 are provided with suffix "C", respectively.

[0104] The strained silicon / s...

embodiment 2

[0118] Embodiment 2

[0119] Embodiment 2 differs from Embodiment 1 in that use of a SOI substrate is substituted for use of the substrate according to Embodiment 1.

[0120] The SOI substrate has a structure, as shown in a sectional view of FIG. 10, wherein an embedded insulating film 13, a strain-relaxed silicon germanium layer 4, and a strained silicon layer 5 are combined in that order on a silicon substrate 1. The silicon substrate 1 is intended only to support those film deposited thereon, and may be made of, for example, quartz, an inorganic oxide ceramic, and so forth, other than silicon.

[0121] With the present embodiment, although the substrate is changed, other steps of a fabrication method can be executed in the same way as those for Embodiment 1. Further, the etching of the silicon germanium layer 4 according to Embodiment 1, as shown with reference to FIG. 6, is stopped at the embedded insulating film 13. Since etch selectivity of silicon germanium to an oxide film is higher ...

embodiment 3

[0122] Embodiment 3

[0123] Embodiment 3 is concerned with a transistor having strained silicon channels of a fin-shaped structure.

[0124] FIG. 12 is a sectional view of a substrate according to the present embodiment. FIGS. 13 and 14 and FIGS. 19 through 29 are schematic illustrations of a device in a fabrication process according to the present embodiment. Suffix "A" of the respective figures indicates a plan view of the device, suffix "B" a sectional view taken on line A-A' of the respective figures with A, and suffix "C" a sectional view taken on line B-B' of the respective figures with suffice "A". FIGS. 24 and 28 are perspective views of the device in the fabrication process.

[0125] FIGS. 15 through 18 are schematic views for illustrating features of a strained silicon layer. FIGS. 15 and 16 are sectional views showing the direction of tensile strain by way of example when a strained silicon layer 5 is grown on a silicon germanium layer 4 while FIGS. 17 and 18 are perspective view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com