Substrate cleaning method, cleaning solution, cleaning apparatus and semiconductor device

a cleaning method and substrate technology, applied in the direction of cleaning using liquids, inorganic non-surface-active detergent compositions, separation processes, etc., can solve the problems of inactivity of cleaning-solution molecules, failure to increase the number of volatile bubbles produced by h.sub.2o, and the generation of standing waves can be prevented. , the effect of preventing the occurrence of standing waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

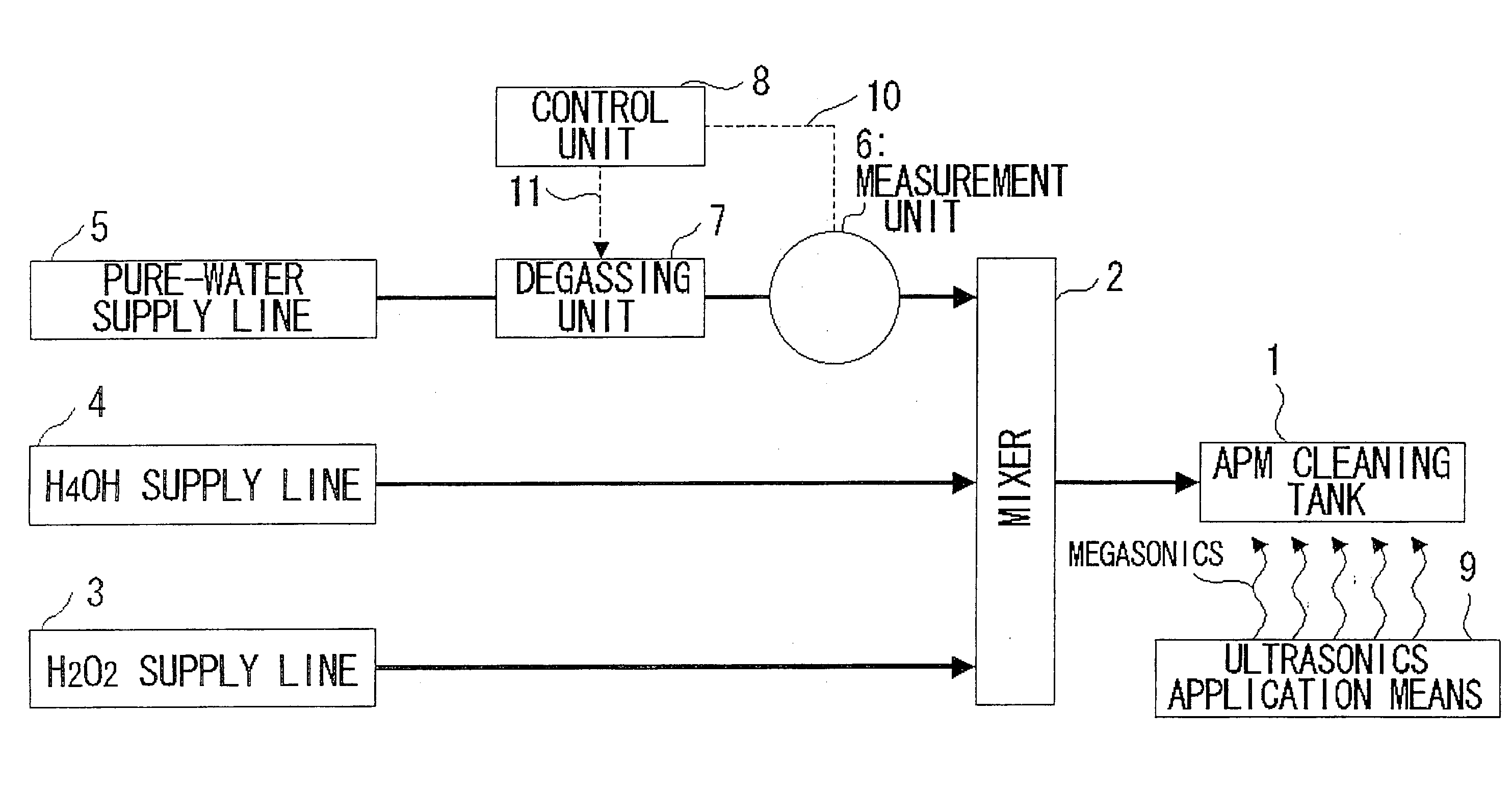

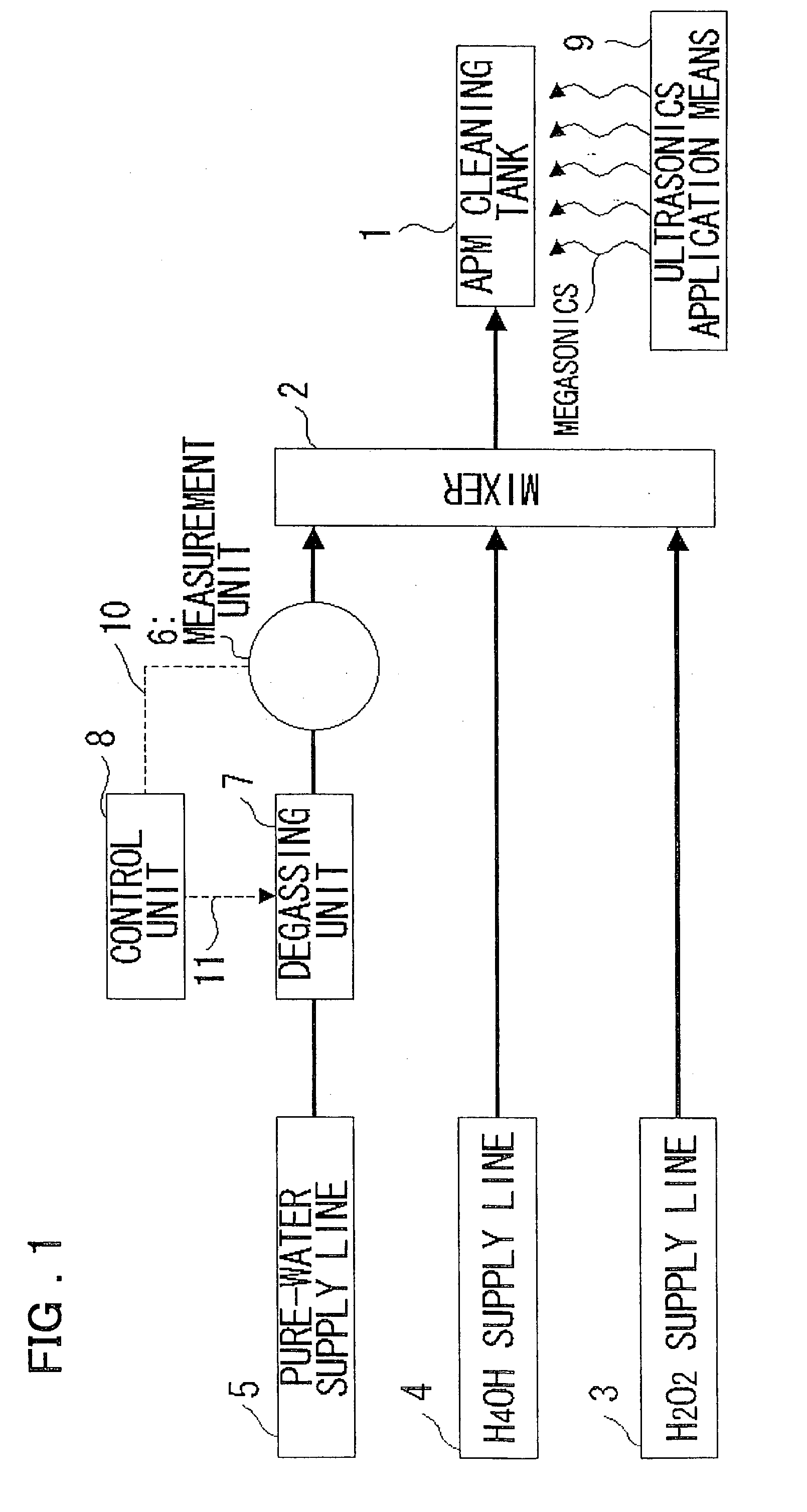

[0037] FIG. 1 is a block diagram schematically illustrating the structure of a cleaning apparatus according to the present invention

[0038] The cleaning apparatus according to the present embodiment is an ultrasonic cleaning apparatus for an APM solution (a mixture of NH.sub.4OH, H.sub.2O.sub.2 and pure water) and is of the type in which the cleaning solution is disposable. The apparatus includes a cleaning tank 1, ultrasonics application means 9, a mixer 2, an H.sub.2O.sub.2 supply line 3, an NH.sub.4OH supply line 4, a pure-water supply line 5, a measurement unit 6, a degassing unit 7 and a control unit 8.

[0039] The cleaning tank 1 accommodates the cleaning solution (APM cleaning fluid) and is for cleaning semiconductor substrates(not shown). The cleaning tank 1 has an inlet section, which is connected to the mixer 2 via piping, for introducing the cleaning solution, and an outlet section from which the cleaning solution flows to the outside after cleaning is performed. The cleanin...

second embodiment

[0056] FIG. 4 is a block diagram illustrating a structure of a cleaning apparatus according to the present invention.

[0057] The cleaning apparatus of this embodiment is an ultrasonic cleaning apparatus for an HPM solution (a mixture of HCl, H.sub.2O.sub.2 and pure water) and is of the type in which the cleaning solution is disposable. With the exception of the fact that the NH.sub.4OH supply line 4 in the cleaning apparatus of FIG. 1 is replaced by an HCl supply line 4a, structurally this embodiment is the same as that of the first embodiment. The HPM solution is used in a case where cleaning is applied to a semiconductor substrate that requires the removal of metallic contaminants from its surface.

[0058] The operation of the cleaning apparatus according to the second embodiment will now be described.

[0059] First, HPM cleaning (metallic cleaning) is performed. The mixer 2 is supplied with hydrogen chloride from the HCl supply line 4a and hydrogen peroxide from the H.sub.2O.sub.2 sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com