Methods and apparatus for improved luminescence assays

a luminescence assay and luminescence technology, applied in the direction of instruments, assay labels, organic chemistry, etc., can solve the problems of slow reaction rate of reaction, inability to use microparticulate matter in luminescence assays, and increase the quantum yield of light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0062] In a third embodiment, the particles may be removed by filtration from the assay composition. In this embodiment the particles need not have a density greater than the balance of the assay composition. The invention, the particles are separated from the solution and concentrated by drawing the solution through a filter, e.g. pumping and collecting the particles on the surface of the filter.

[0063] In a preferred embodiment, the suspended particles are magnetically responsive, e.g. they may be paramagnetic or ferromagnetic, and are collected in a measurement zone by imposition of a magnetic field on the particles. The measurement cell is equipped with a magnet. The magnetic field of the magnet applies a force on the particles as they reside in a batch cell or as they flow through a flow cell, causing them to separate from the bulk of the solution onto the surface of the cell which is in closest proximity to the magnet.

[0064] Several different heterogeneous and homogeneous forma...

example 1

Chemiluminescent Apparatus and Method for Deposition of Microparticles

[0108] Magnetic Collection using a Sedimentation Cell.

[0109] A cell for conduct of an assay using magnetic force to cause the microparticulate to settle is shown in FIG. 5. Reference numeral 21 refers to a transparent window, reference numeral 22 to a gasket, reference numeral 23 to the inlet in the cell block, reference numeral 25 to the sample outlet, reference numeral 26 to the cell block itself and reference 27 to an electromagnet.

[0110] The plane of the cell block is oriented horizontally. Labeled microparticles (Dynal) in buffer are drawn to the cell by means of a peristaltic pump. The pump is turned off after the microparticles reach the cell. The microparticles in the cell chamber are drawn to the collection zone by means of a magnetic field generated using electromagnet 27 operating at 12 volts and 1.5 amps. By application of the electromagnet, the rate of deposition of microparticles is greatly increased...

example 2

Chemiluminescent Apparatus and Method for Deposition of Microparticles

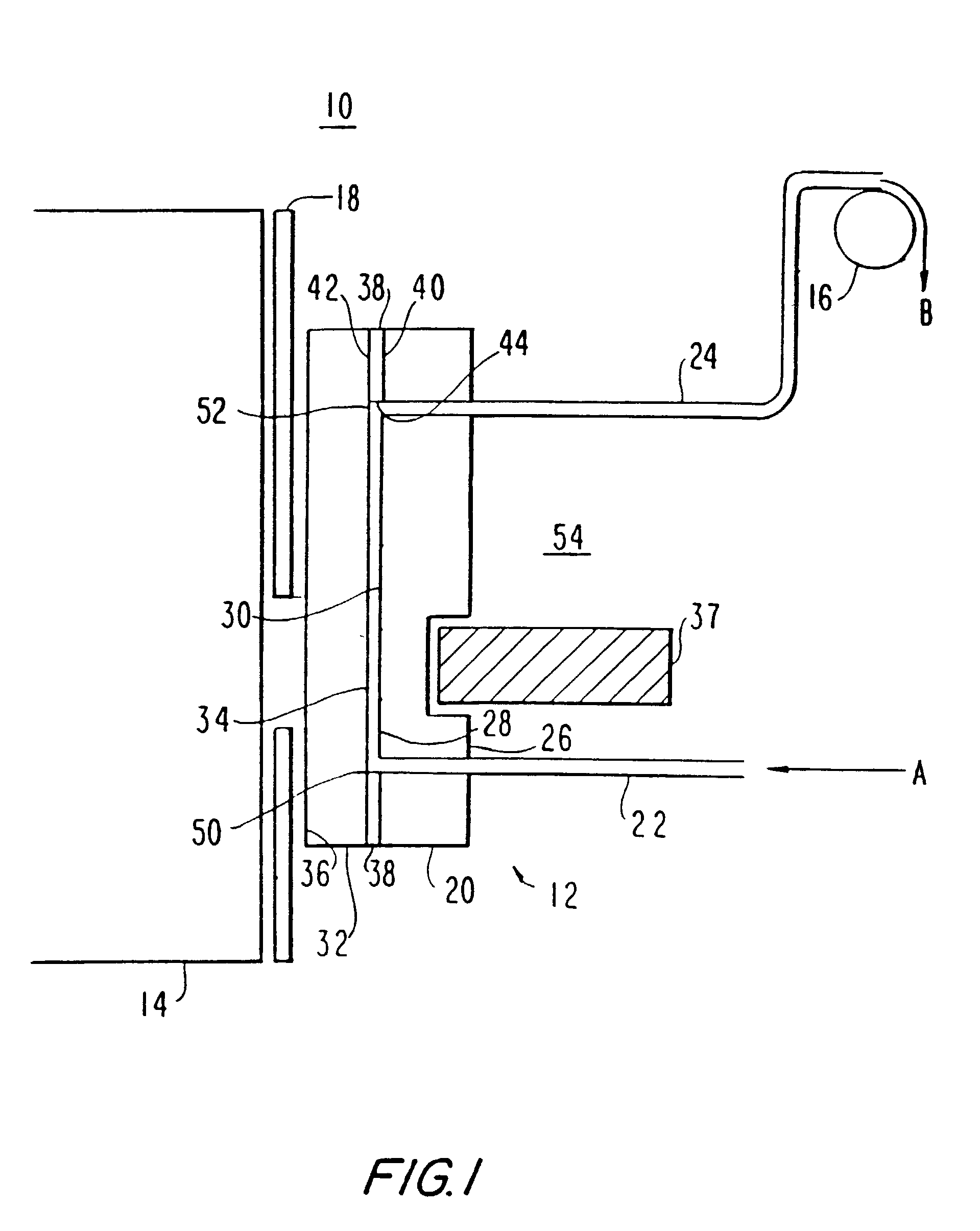

[0111] Magnetic Collection Using a Collection Cell.

[0112] An assay is carried out in a cell as described in FIG. 1. With reference to FIG. 1, reference numeral 32 refers to transparent window, reference numeral 38 to a gasket, reference numeral 22 to an inlet in the cell block, reference numeral 20 to the cell block itself, reference numeral 24 to the sample outlet and reference numeral 37 to a permanent magnet.

[0113] The plane of the cell block is oriented horizontally. Labeled microparticles (Dynal) in buffer are drawn to the cell by means of a peristaltic pump 11. Prior to the sample introduction, permanent magnet 37 is positioned immediately below the collection zone at a distance of 0.035 inches. As the sample is being drawn to the cell, the microparticles collect in a collection zone, as defined by the area of the magnet. The pump is turned off. The longer the collection time, the more particles are collecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com