Methods and apparatus for transferring electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

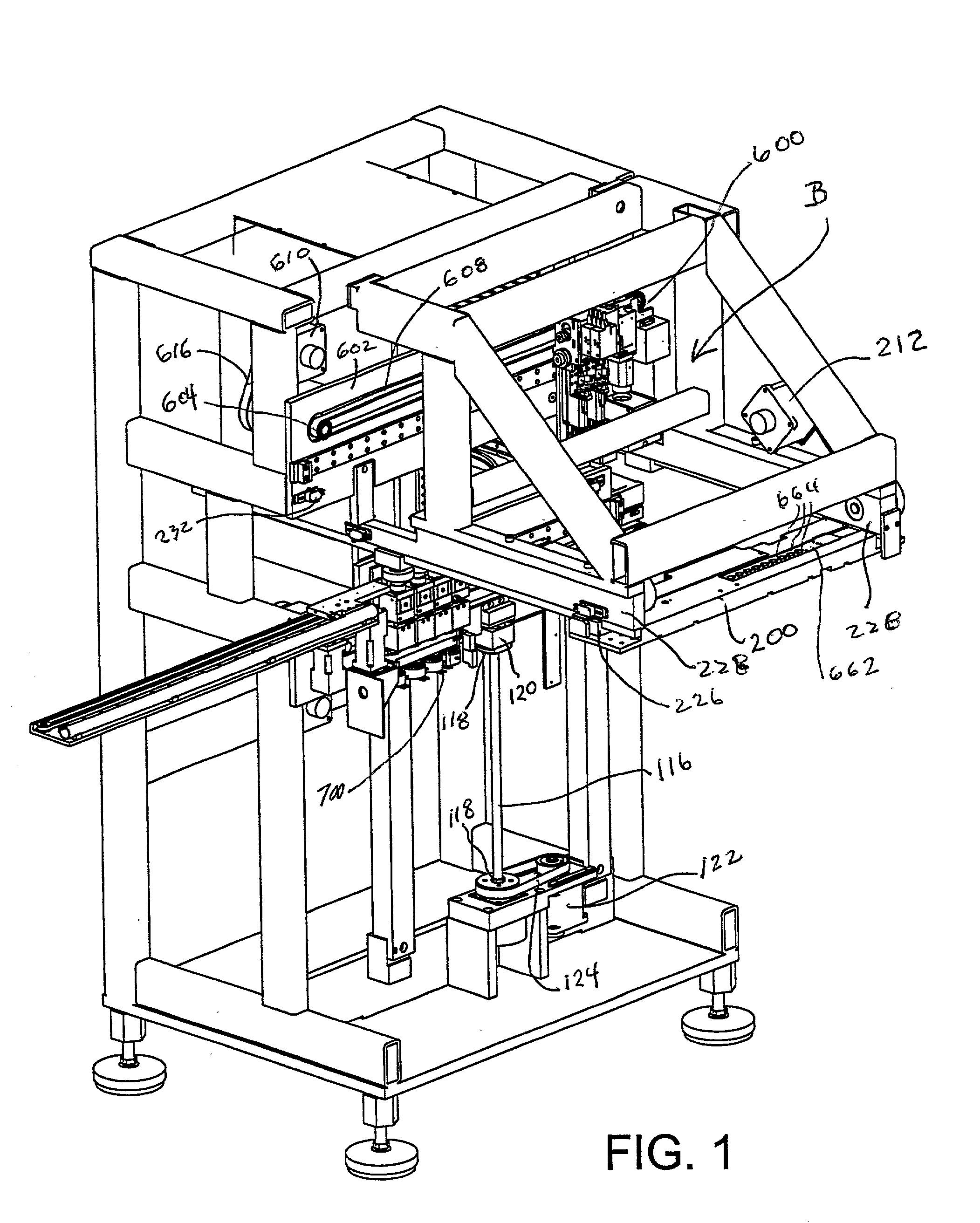

[0043] An apparatus for removing individual dies from a semiconductor wafer comprises a wafer feed section A in which a plurality of wafers are provided, a pick and place section B where individual dies are removed from the wafers, and a receiver section C where the removed dies are deposited for further handling.

[0044] Wafer Feed Section

[0045] The wafer feed section A comprises a stationary base frame 102 to which an elevator 104 is mounted for up / down movement (see FIG. 3). The elevator includes a pair of parallel vertical side walls 106 of identical configuration. The side walls are interconnected by top and bottom walls 108, 110 to form a rigid structure.

[0046] Each side wall 106 includes an inner surface in which are formed a plurality of parallel, horizontally extending slots 112 or 112' spaced equidistantly apart in the vertical direction. The slots 112 on one side wall are horizontally aligned with, and arranged parallel to, respective ones of the slots 112' formed on the ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com