Printing apparatus and head driving method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fifth embodiment

[0222] [Fifth Embodiment]

[0223] In a fifth embodiment, printing registration is performed between a plurality of heads in a carriage scanning direction.

[0224] (Explanation of Printing Registration Pattern)

[0225] Concerning the printing pattern explained in the fourth embodiment, dots printed in the forward scan is printed by a first head in the present embodiment, and the dots printed in the reverse scan is printed by a second head in the present embodiment, for performing printing registration. Judgment method of the printing registration condition is similar to that in the fourth embodiment.

[0226] (Optimum Ink Ejection Duty Judgment Pattern)

[0227] Concerning a plurality of heads to be used, the pattern for making judgment of the optimum ink ejection duty is printed similarly to the fourth embodiment, for measuring the optical reflection index for respective patches. A linear region where the optical reflection index with respect to the ink ejection duty is linearly varied is deter...

sixth embodiment

[0231] [Sixth Embodiment]

[0232] In a sixth embodiment, printing registration is performed in a direction perpendicular to a carriage scanning direction between a plurality of heads.

[0233] (Explanation of Printing Registration Pattern)

[0234] In the present embodiment, there is used a printing pattern where the relationship between vertical and lateral directions is reversed in the printing pattern explained in the fifth embodiment. The judgment method of the printing registration condition is similar to that in the fourth embodiment.

[0235] (Optimum Ink Ejection Duty Judgment Pattern)

[0236] In the same manner as in the fifth embodiment, concerning a plurality of heads to be used, the pattern for making judgment of the optimum ink ejection duty is printed similarly to the fifth embodiment, for measuring the optical reflection index for respective patches. A linear region where the optical reflection index with respect to the ink ejection duty is linearly varied is determined on the bas...

seventh embodiment

[0241] [Seventh Embodiment]

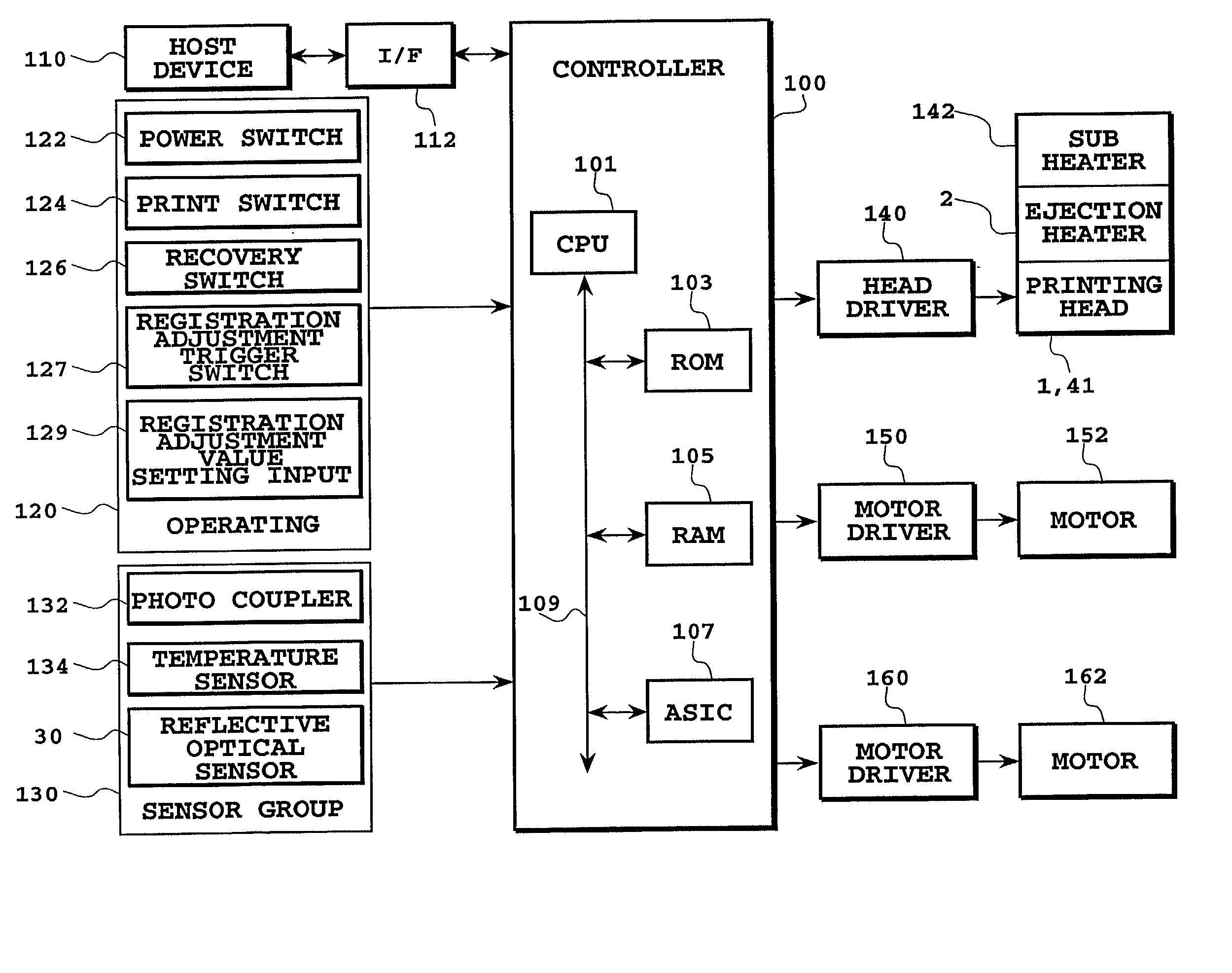

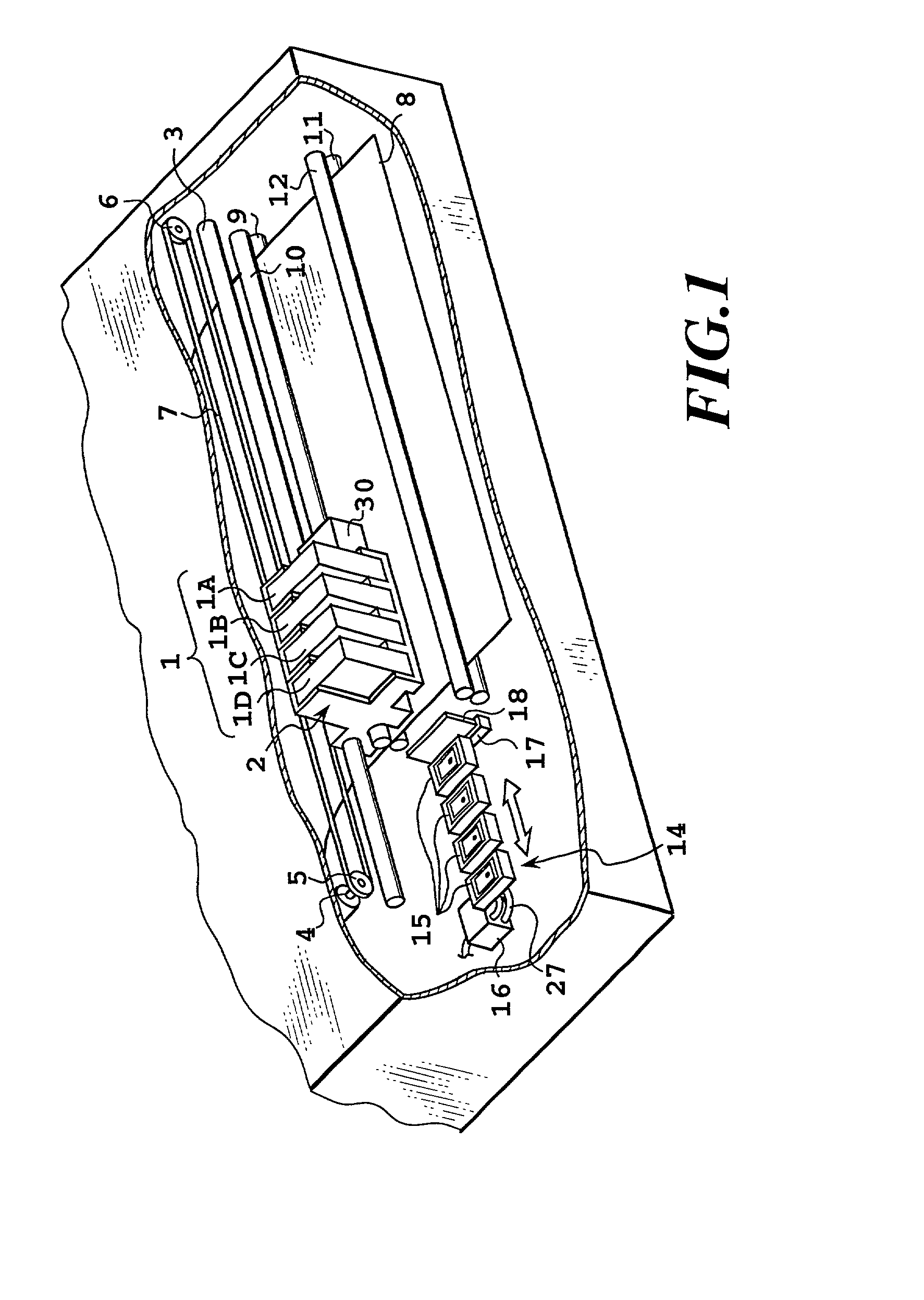

[0242] Seventh to tenth embodiments are suitable for performing printing using high density and low density inks in the printing apparatus shown in FIGS. 1 and 2.

[0243] Printing can be performed by using both of the high density ink and an ink diluted about three or four times with the high density ink (low density ink), or by using only the diluted ink (low density ink). In this case, the head must be frequently replaced for printing of an image primarily consisting of a text and for printing of an image primarily consisting of a graphic image, so that it becomes necessary to frequently perform printing registration.

[0244] However, when the user selects the condition where the printing positions are well registered by visual observation, the rules are printed on the printing medium with the high density ink and the low density ink. As a result, since the printing registration condition is determined by the user, it is possible to make it difficult to judg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com