Simultaneous slicing and washing of vegetables

a technology of simultaneous slicing and washing of vegetables, applied in the direction of milk preservation, application, cleaning using liquids, etc., can solve the problems of undesirable film presence, minimize the overlap of slices, and reduce the tendency to form clumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

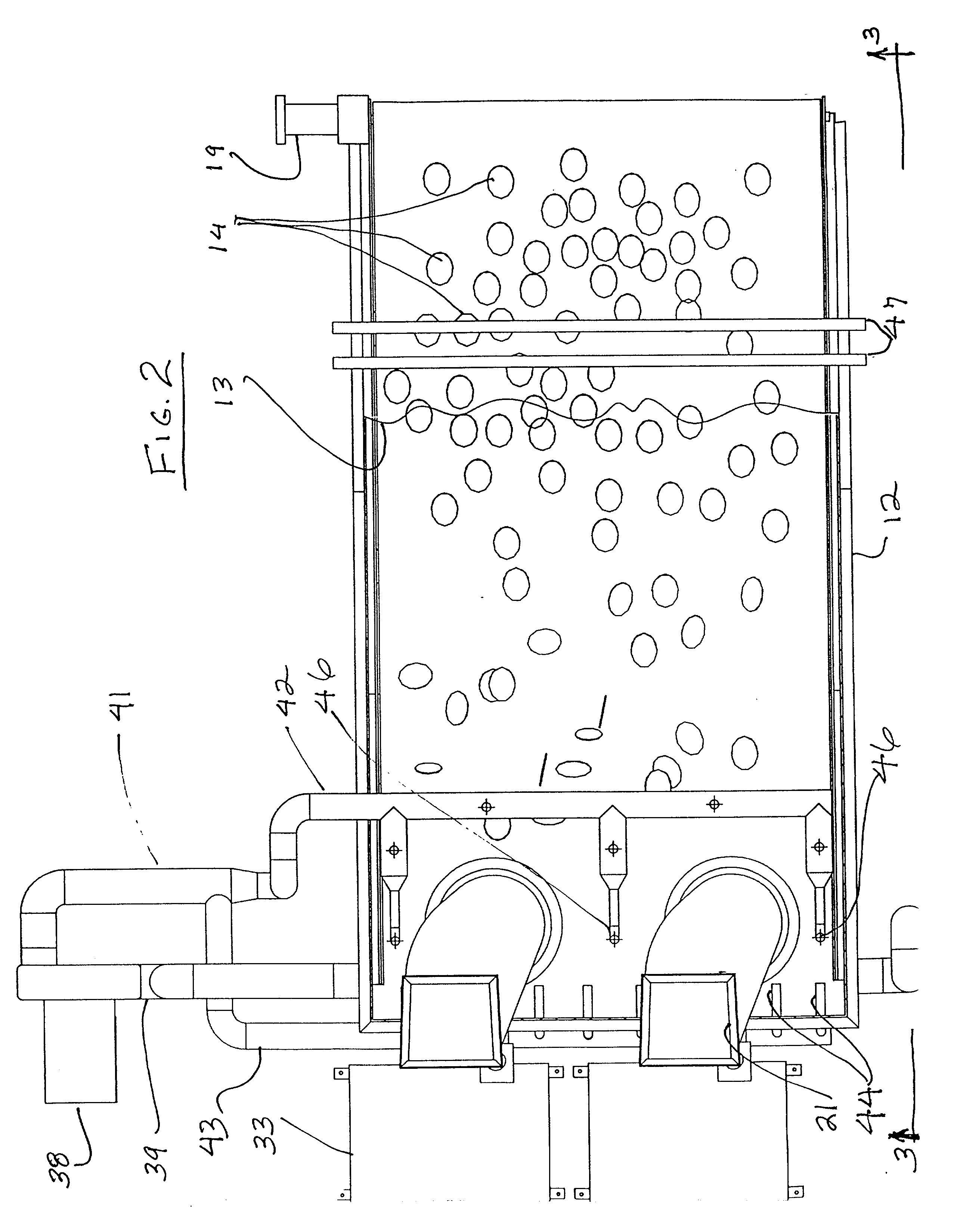

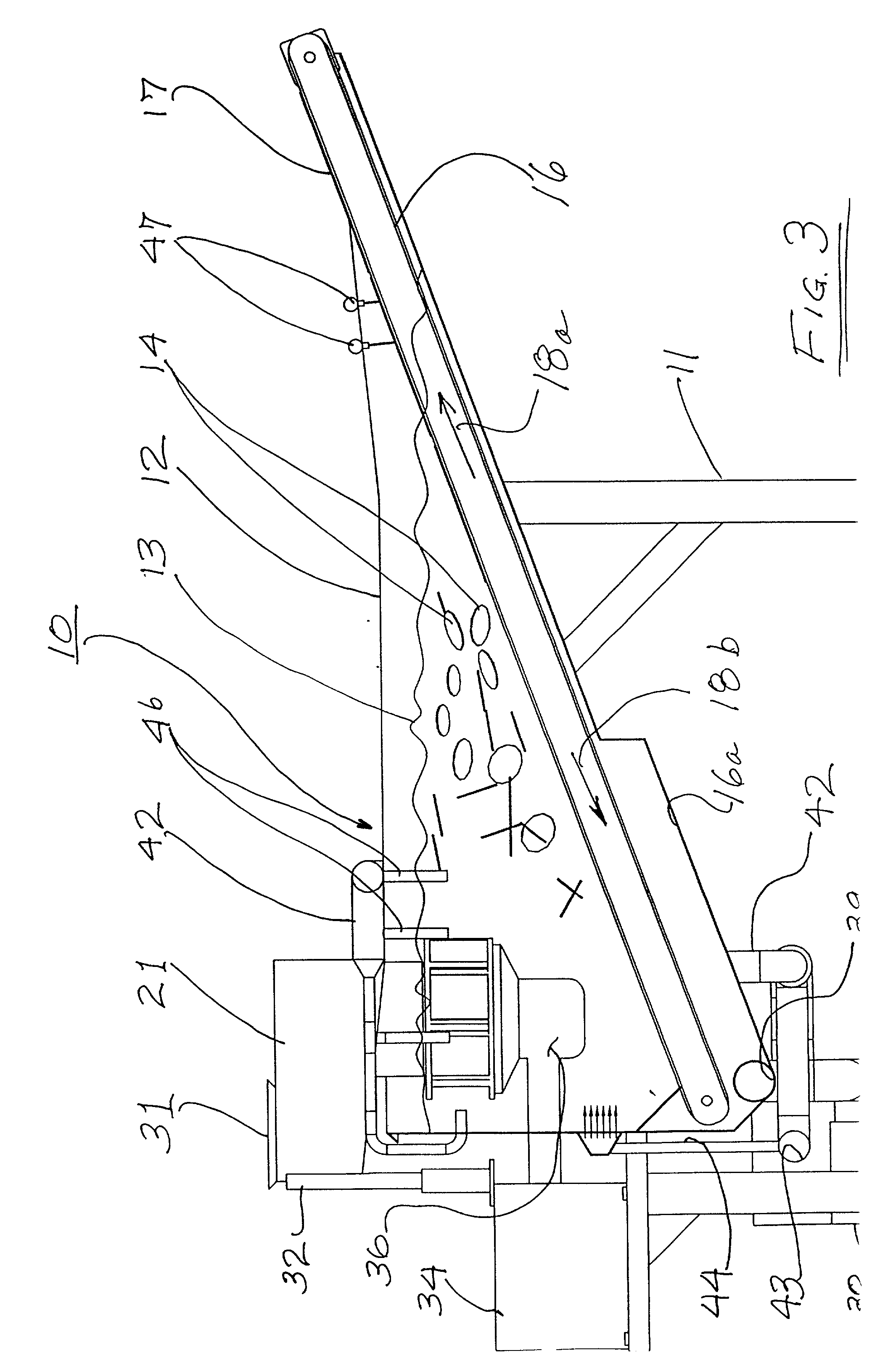

[0020] Referring to the drawings FIGS. 1-3, there is shown a first preferred embodiment, an apparatus 10 especially adapted for carrying out the principles of the invention in simultaneously slicing and washing a vegetable product. The vegetable product may be any from the group comprising potatoes, apples, sweet potatoes, cassava, plantains, beets, onions, water chestnuts, cabbage, carrots, turnips and sugar beets. The slicer-washer apparatus 10 includes an upstanding frame 11 which supports a metal tub or bath 12 which is generally wedge-shaped in elevation as seen in FIG. 3 and, as shown in plan view in FIG. 2, is generally rectilinear. An important function of the tub 12 is to contain a body of water 13 as indicated by the wavy lines of FIGS. 1 and 3. The purpose of the water is to serve as a medium for washing broken cells, starch particles, dirt and the like from a multiplicity of vegetable slices 14 as symbolized by the oval elements in FIGS. 1-3.

[0021] A bottom wall 16 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com