Method of modifying a surface of an insulator

a technology of insulator and surface, applied in the field of surface modification, can solve the problems of excessive elongation of process time, inability to easily improve productivity, and limited application method of electric beam of the foregoing type, so as to achieve the effect of reducing time required to complete the process, reducing labor intensity, and efficient subjecting to the surface modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second example

[0062] In this example, a plastic substrate obtained by molding polyimide resin was employed as the work 11 which must be processed. Then, the surface modification was performed similarly to the first example. Then, wettability of the plastic substrate subjected to the surface modification with respect to water was measured. The measurement was performed by using a contact angle meter (CA-D contact angle meter manufactured by Kyowa Interface). As a result, the contact angle between the plastic substrate which was not subjected to the surface modification and water was 106.degree.. On the other hand, the angle of contact between the plastic substrate subjected to the surface modification and water was 50.degree.. Therefore, the method for surface modification according to the present invention was able to modify the surface of the plastic substrate and change the wettability.

[0063] Then, electric resistance of the surface of the plastic substrate was measured. Thus, the electric resi...

third example

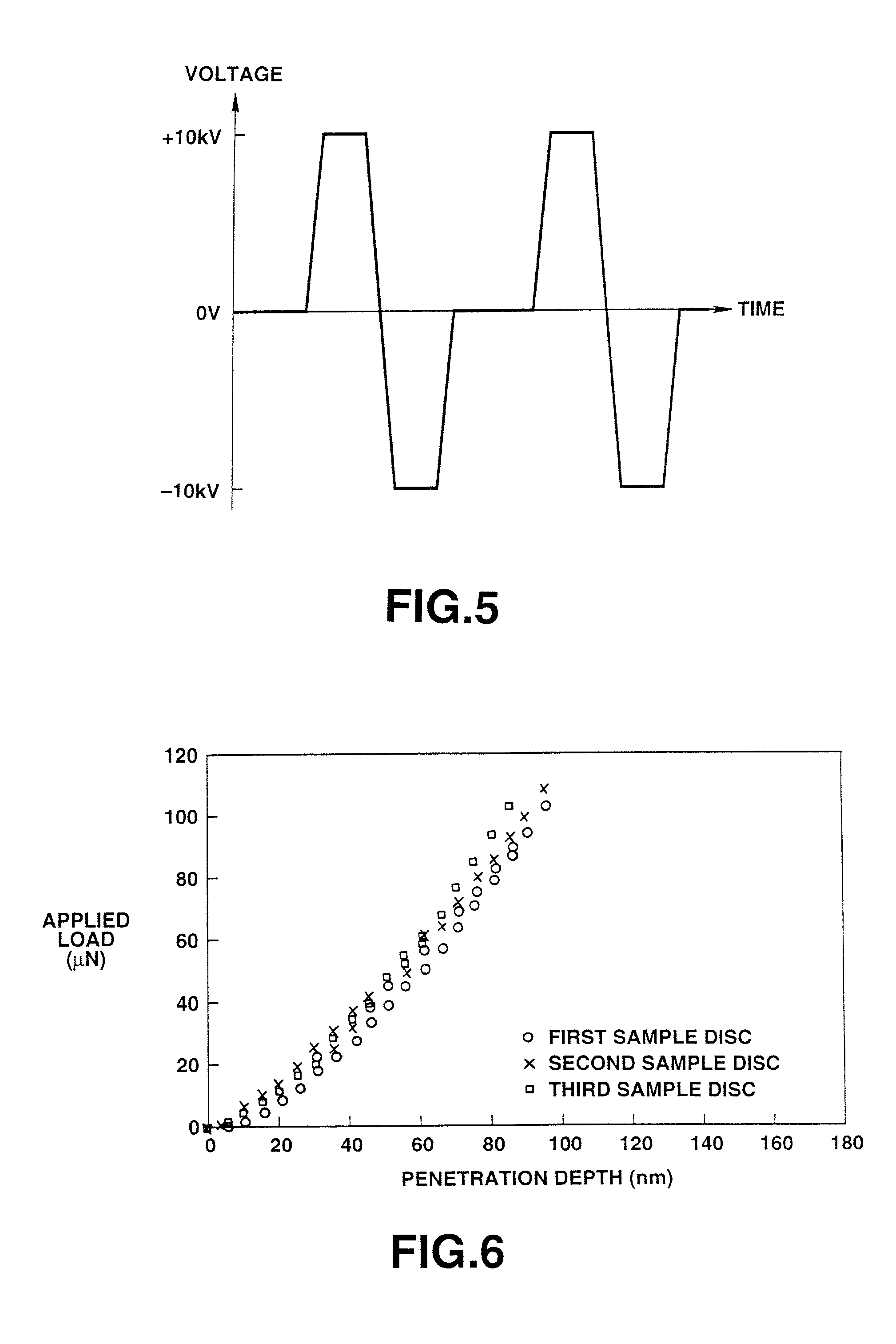

[0064] In this example, a plastic substrate obtained by molding amorphous polyolefine (APO) was employed as the work 11 which must be processed. Then, the surface modification was performed similarly to the first example. In the third example, the pulse-shape voltage which was applied to the plastic substrate had a waveform similarly to the first example and as shown in FIG. 5 such that the positive pulse-shape voltage and the negative pulse-shape voltage alternately appeared.

[0065] In the third example, three sample discs were manufactured under the following surface modification conditions. The other conditions were the same as those in the first example.

[0066] Surface Modification Conditions

[0067] Pulse Peak Voltage: +10 kV, -10 kV

[0068] Interval between Pulses: 10 msec (10 kHz)

[0069] Process Duration: 10 minutes

[0070] Each of the manufactured sample discs was subjected to the nano-indentation test similarly to the first example. Results of the measurement were shown in FIG. 6. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com