Vacuum cleaner nozzle having rotatable brush

a vacuum cleaner and rotatable technology, which is applied in the direction of brushes, suction cleaners, domestic applications, etc., can solve the problems of polluting the rotatable brush, hindering the cleaning ability, and users are unable to see if the rotatable brush is polluted, so as to achieve easy identification of the different power settings, easy cleaning, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

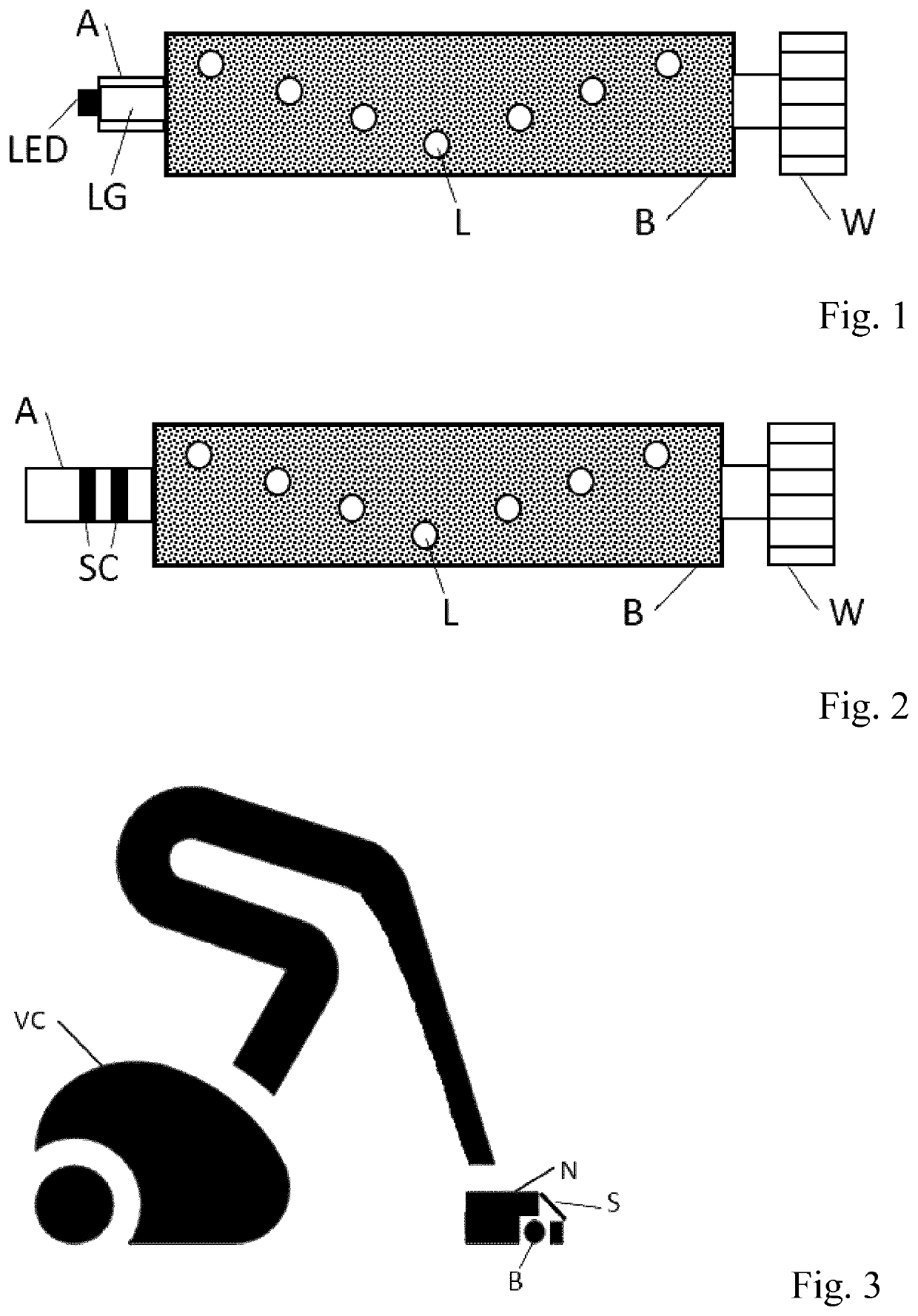

[0013]a rotatable brush for use in a vacuum cleaner nozzle in accordance with the invention is shown in FIG. 1. The rotation around an axis A is caused by a motor which is connected to the rotatable brush B by way of gears or pulley that drive a wheel W. The rotatable brush B has a transparent light conducting material in its core that acts as a light guide LG. Further, the core has radially placed holes or light guides in the core in order to guide the light from the core to the outer part of the rotatable brush roll where it can radiate to the ambience via a plurality of openings L. Further, one or more LEDs are positioned in the vacuum cleaner nozzle in such a place that the LED does not rotate but shines light in axial direction into the transparent core of the rotatable brush B. The LED is therefore positioned in a static part of the vacuum cleaner nozzle, and the LED is thus not vulnerable to high rotation speed or pollution of connection. Also, as the LED is in a static part,...

second embodiment

[0021]FIG. 2 shows a rotatable brush for use in a vacuum cleaner nozzle in accordance with the invention. This embodiment differs from that of FIG. 1 in that the axis A is provided with sliding contacts SC by means of which electrical energy can be transmitted to the rotatable brush B. In this way, it is possible to power an LED in the rotatable brush B that applies light to a light guide from which light escapes at the plurality of openings L. Alternatively, at each of these openings L a separate LED is provided.

[0022]FIG. 3 shows an embodiment of a vacuum cleaner VC comprising a vacuum cleaner nozzle N having a rotatable brush B in accordance with the invention. The vacuum cleaner nozzle N has a transparent screen S through which a user can see the rotatable brush B. If the rotatable brush B rotates, the user will see the rotating lights from the rotatable brush B through the screen S. The vacuum cleaner nozzle N comprises a drive unit to make the rotatable brush B rotate. The dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com