Densifier for aqueous breakdown fluid and its production method

A water-based fracturing and thickening agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high sand carrying capacity, poor salt resistance, good shear resistance, etc., and achieve high carrying capacity Sand and residue-free, good shearing and sand-carrying performance, and good sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

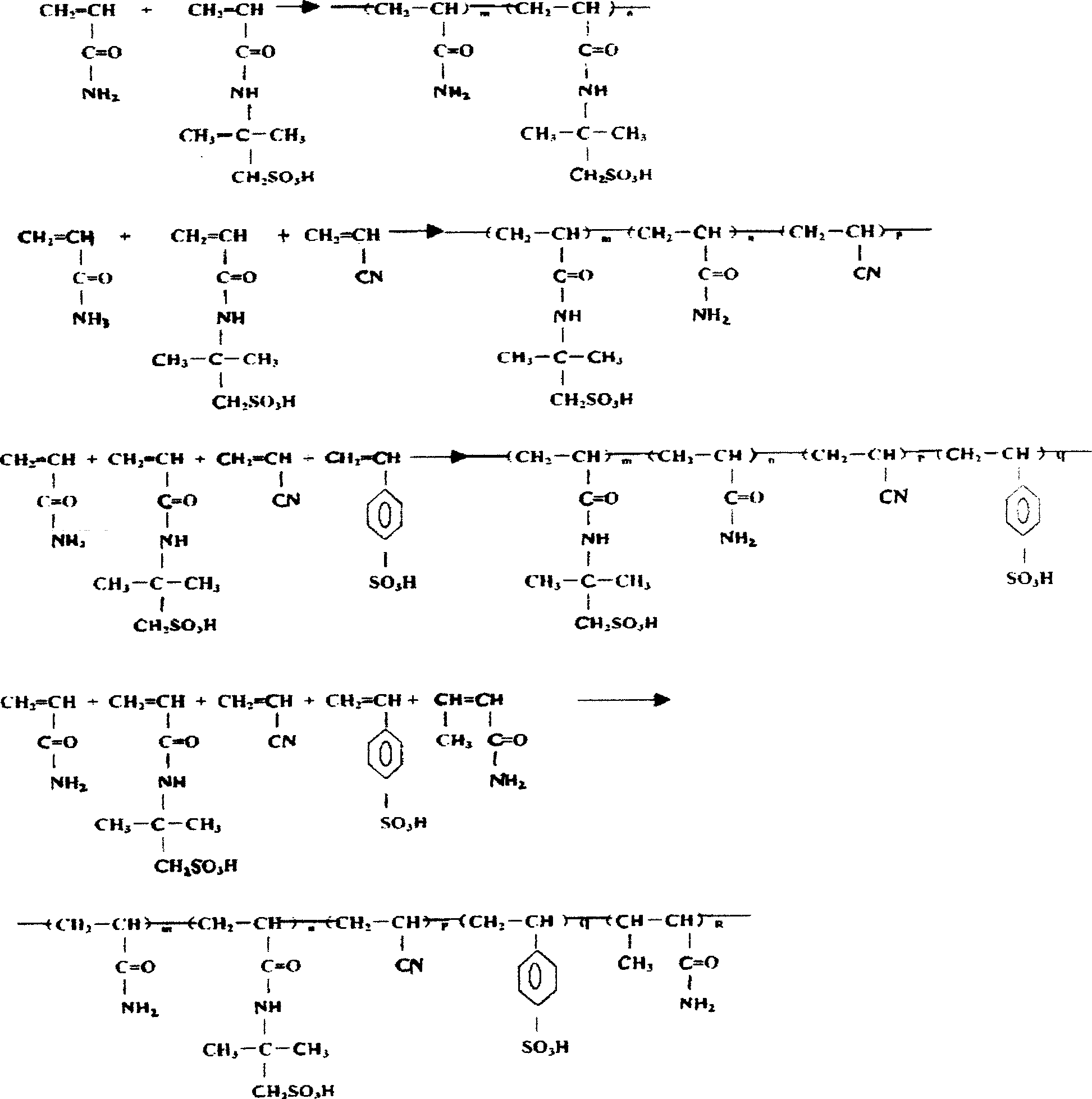

Method used

Image

Examples

Embodiment 1

[0045] The weight percent of each monomer and water: AM: AMPS: BNS: AAM: AN: DMC: PVN: H 2 O=15:25:5:1.5:0.5:2:0.5:50.5.

[0046] Preparation of the solution: add 370g of distilled water into a 2000ml beaker, add 250g of AMPS monomer, 50g of BNS monomer, stir and dissolve for 20 minutes, slowly add neutralizer (sodium hydroxide) under stirring condition until the pH is neutral. Then add 150 g of 98% acrylamide, 15 g of AAM monomer, 5 g of AN monomer, 20 g of 80% concentration DMC monomer, and 5 g of PVN monomer, and stir to dissolve for 30 minutes.

[0047] Adjustment of the solution: adjust the pH value to 10±0.5, and adjust the temperature to 10±1°C.

[0048] Polymerization of the solution: Blow nitrogen to deoxygenate for 15-20 minutes, add catalysts AZDN0.5g / L, V500.05g / L, ammonium persulfate 0.03g / L, sodium formaldehyde sulfoxylate 0.03g / L in sequence under nitrogen protection , stop blowing nitrogen, and trigger for 15-20 minutes. When the temperature rises to 30°C, pu...

Embodiment 2

[0051] The weight percent of each monomer in water: AM: AMPS: BNS: AAM: AN: DMC: PVN: H 2 O=30:25:0.5:0:0.3:0:0:44.2.

[0052] Preparation of the solution: add 442g of distilled water into a 2000ml beaker, add 250g of AMPS monomer, 5g of BNS monomer, stir and dissolve for 20 minutes, slowly add neutralizer (sodium hydroxide) under stirring condition until the pH is neutral. Then add 300 g of 98% acrylamide, 0 g of AAM monomer, 0.3 g of AN monomer, 0 g of 80% concentration DMC monomer, and 0 g of PVN monomer, and stir to dissolve for 30 minutes.

[0053] Adjustment of the solution: adjust the pH value to 10±0.5, and adjust the temperature to 10±1°C.

[0054] Polymerization of the solution: Blow nitrogen to deoxygenate for 15-20 minutes, add catalysts AZDN0.5g / L, V500.04g / L, ammonium persulfate 0.03g / L, sodium formaldehyde sulfoxylate 0.03g / L in sequence under nitrogen protection , stop blowing nitrogen, and trigger for 15-20 minutes. When the temperature rises to 30°C, put it i...

Embodiment 3

[0057] The weight percent of each monomer and water: AM: AMPS: BNS: AAM: AN: DMC: PVN: H 2 O=30:7:6.5:0:2:0:0:54.5.

[0058] Preparation of the solution: Add 545g of distilled water into a 2000ml beaker, add 70g of AMPS monomer, 65g of BNS monomer, stir and dissolve for 20 minutes, and slowly add neutralizer (sodium hydroxide) under stirring condition until the pH is neutral. Then add 300 g of 98% acrylamide, 0 g of AAM monomer, 20 g of AN monomer, 0 g of 80% concentration DMC monomer, and 0 g of PVN monomer, and stir to dissolve for 30 minutes.

[0059] Adjustment of the solution: adjust the pH value to 10±0.5, and adjust the temperature to 10±1°C.

[0060] Polymerization of the solution: Blow nitrogen to deoxygenate for 15-20 minutes, add catalysts AZDN 0.8g / L, V50 0.08g / L, ammonium persulfate 0.04g / L, sodium formaldehyde sulfoxylate 0.04g / L in sequence under nitrogen protection , stop blowing nitrogen, and trigger for 15-20 minutes. When the temperature rises to 30°C, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com