Conical pressureless fed three-product dense-medium cyclone

A technology of dense medium cyclone and cyclone, which is applied in the field of separation, can solve the problems of serious environmental pollution, high cost of mineral processing, and failure to achieve the effect of simple production process, significant economic benefits, and small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

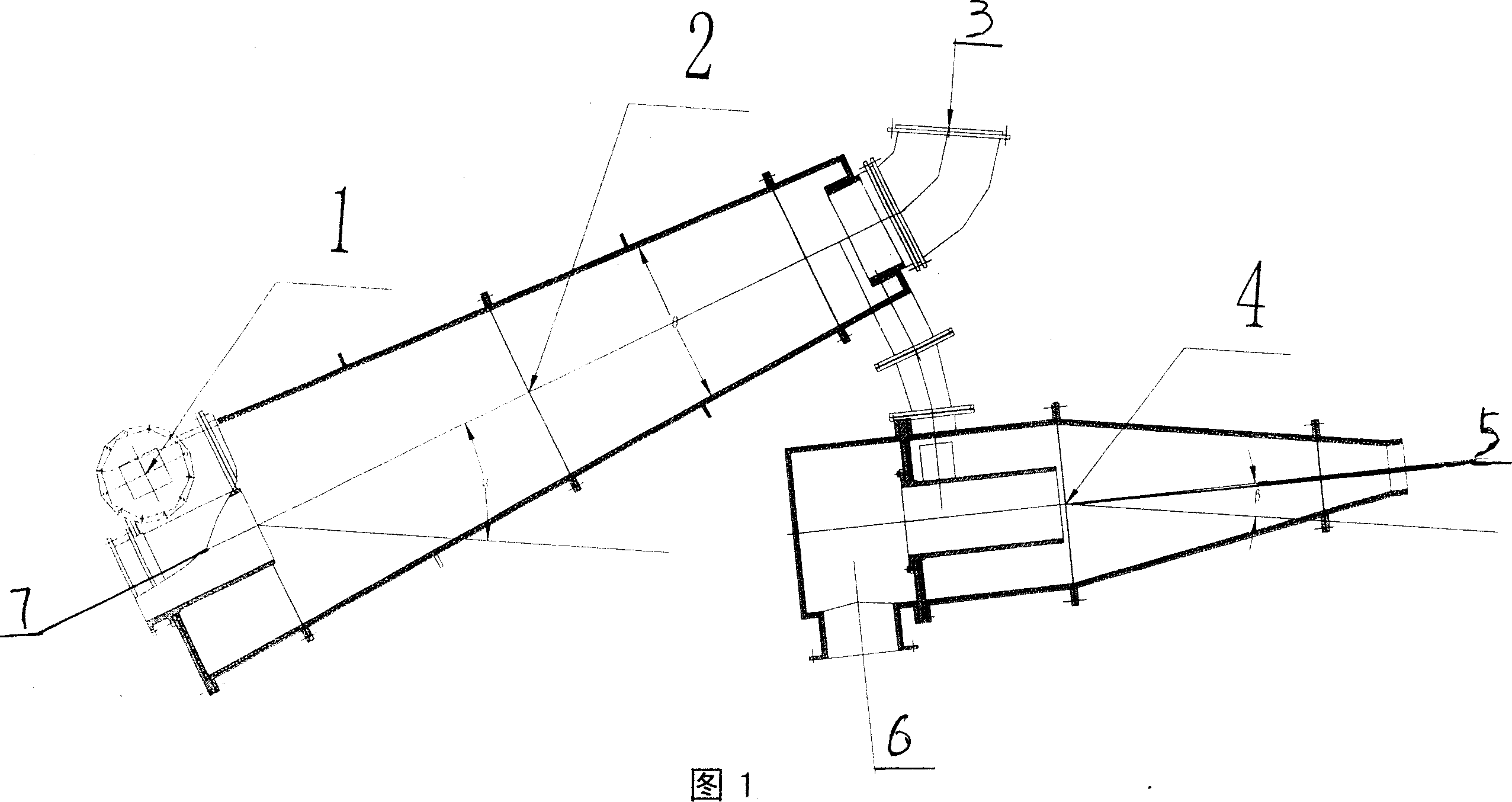

[0011] The present invention is an improvement to the prior art, and the improvement is that a section of the three-product dense medium cyclone is changed from a cylindrical cyclone to a conical cyclone. Referring to accompanying drawing 1, the present invention is by unpressurized feeding conical cyclone, i.e. one section conical cyclone 2 and pressurized feeding cylindrical conical cyclone, i.e. second section cylindrical conical cyclone 4 Composed in series. The cone angle θ of the first-stage conical cyclone 2 is between 5° and 40°, the installation inclination angle α (the angle between the central axis and the horizontal) is between 25° and 50°, and the second-stage cylindrical conical cyclone The installation inclination angle β (the angle between the central axis and the horizontal) is between 5° and 90°. A heavy medium suspension in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com