Continuous countercurrent extraction method using dynamic overflow and apparatus thereof

An extraction method and overflow technology, applied in the direction of solid solvent extraction, etc., can solve the problems of reducing the amount of solvent and extraction temperature, long extraction time, and lower product quality, and achieve the goals of shortening the extraction cycle, prolonging the extraction time, and shortening the extraction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

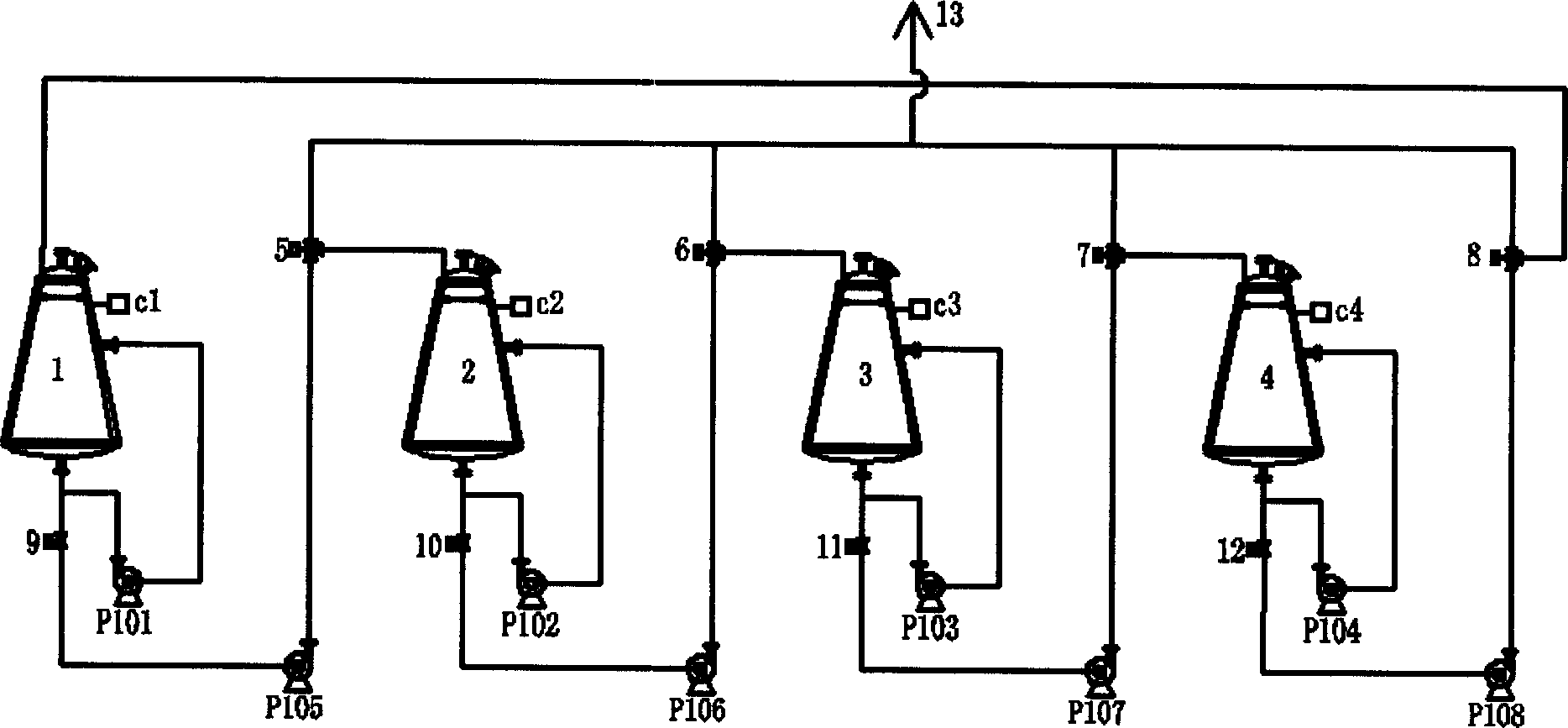

Embodiment 1

[0042] Put in and process Danshen medicinal materials, the particle size is 0.3-0.5cm, the solvent is water, and the extraction unit is 4 groups. 20kg per tank, add 4 times the amount of water to 1# tank, keep warm at 70-80°C, reflux for 25 minutes, start to actively overflow from the pump to 2# tank through the pipeline, and at the same time add fresh solvent; 2# tank starts heating, 25 minutes Finally, the 2# tank is actively overflowed by the pump through the pipeline to the 3# tank; the 3# tank starts to be heated, and after 25 minutes, the 3# tank overflows to the 4# tank by the pump through the pipeline; the 4# tank starts to heat, 25 minutes Minutes later, the 4# tank began to discharge liquid, and the 1# tank stopped adding fresh solvent; 13 minutes later, the 1# tank discharged the medicinal residue, added fresh medicinal materials, the 4# tank liquid stopped, and the pump began to actively send the solvent to the 1# tank through the pipeline. For overflow, add fresh ...

Embodiment 2

[0050] Put into processed notoginseng medicinal materials, the particle size is 0.3-0.5cm, the solvent is 75% ethanol, and the extraction unit is 9 groups. 20kg per tank, add 4 times the amount of solvent to 1# tank, keep warm at 65-75°C, reflux for 15 minutes, start to actively overflow from the pump to 2# tank through the pipeline, and add solvent continuously; 2# tank starts to heat, after 15 minutes , the 2# tank is actively overflowed from the pump to the 3# tank through the pipeline; the 3# tank starts to heat, and after 15 minutes, the 3# tank actively overflows from the pump to the 4# tank through the pipeline; the 4# tank starts to heat, and after 15 minutes , the pump began to actively overflow to the 5# tank through the pipeline; the 5# tank began to heat, and after 15 minutes, the 5# tank actively overflowed from the pump to the 6# tank through the pipeline; the 6# tank began to heat, and after 15 minutes, the 6 Tank # is actively overflowing from the pump to tank ...

Embodiment 3

[0052]Put in and process ginseng medicinal materials, the particle size is 0.3-0.5 cm, the solvent is 75% ethanol, and the extraction unit is 6 groups. 20kg per tank, add 4 times the amount of solvent to 1# tank, keep warm at 65-75°C, reflux for 20 minutes, start to actively overflow from the pump to 2# tank through the pipeline, and add solvent continuously; 2# tank starts to heat, after 20 minutes , the 2# tank is actively overflowed from the pump to the 3# tank through the pipeline; the 3# tank starts to heat, and after 20 minutes, the 3# tank actively overflows from the pump to the 4# tank through the pipeline; the 4# tank starts to heat, and after 20 minutes , the 4# tank began to actively overflow from the pump to the 5# tank through the pipeline; the 5# tank began to heat, and after 20 minutes, the 5# tank actively overflowed from the pump to the 6# tank through the pipeline; the 6# tank began to heat up, 20 minutes 10 minutes later, 1# tank, the medicine dregs were dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com