System and method for transfer of feedback control for a process control device

A process control, feedback control technology, applied in general control systems, control/regulation systems, program control, etc., to solve problems such as downtime, inoperability, process or plant accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

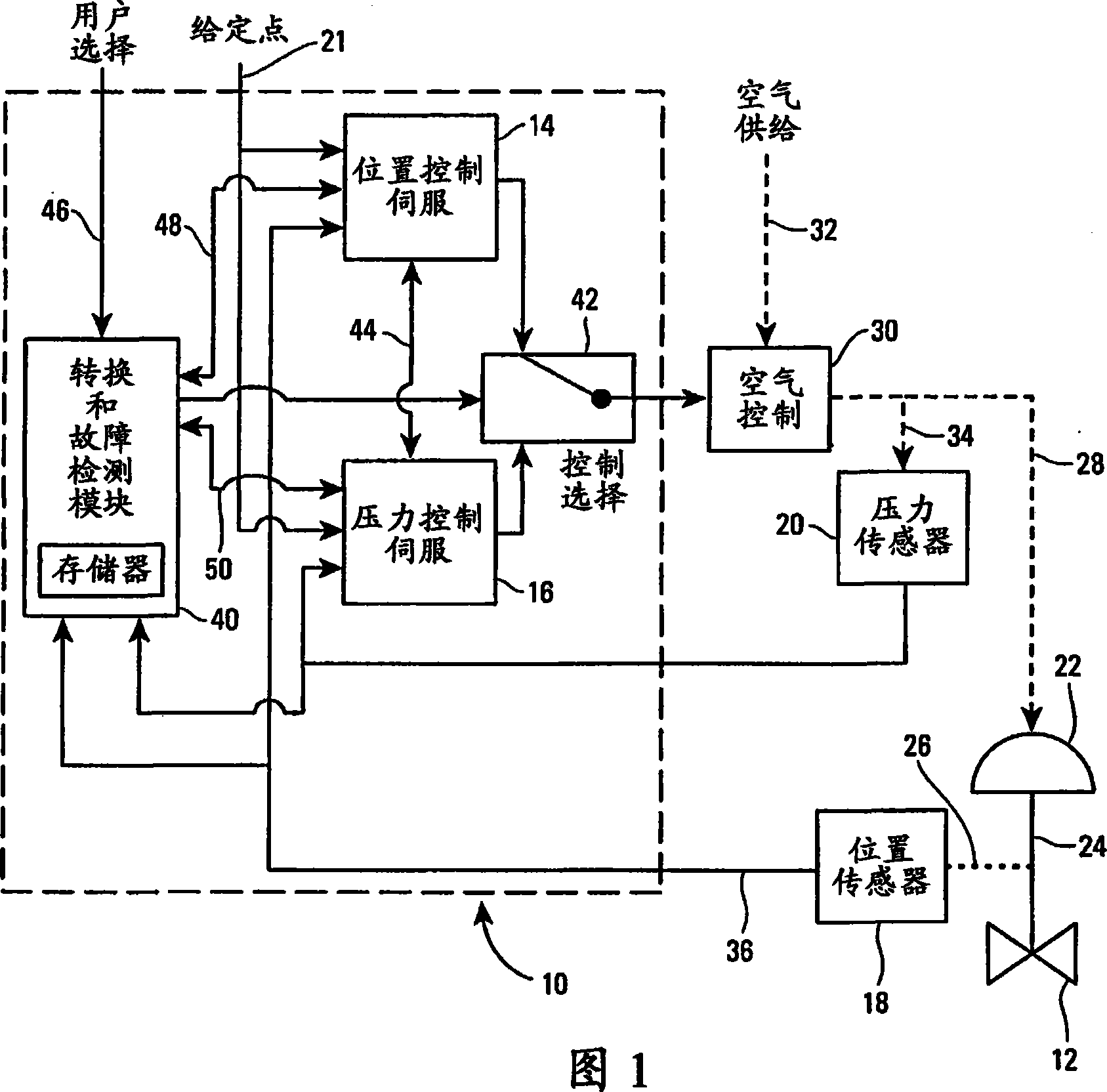

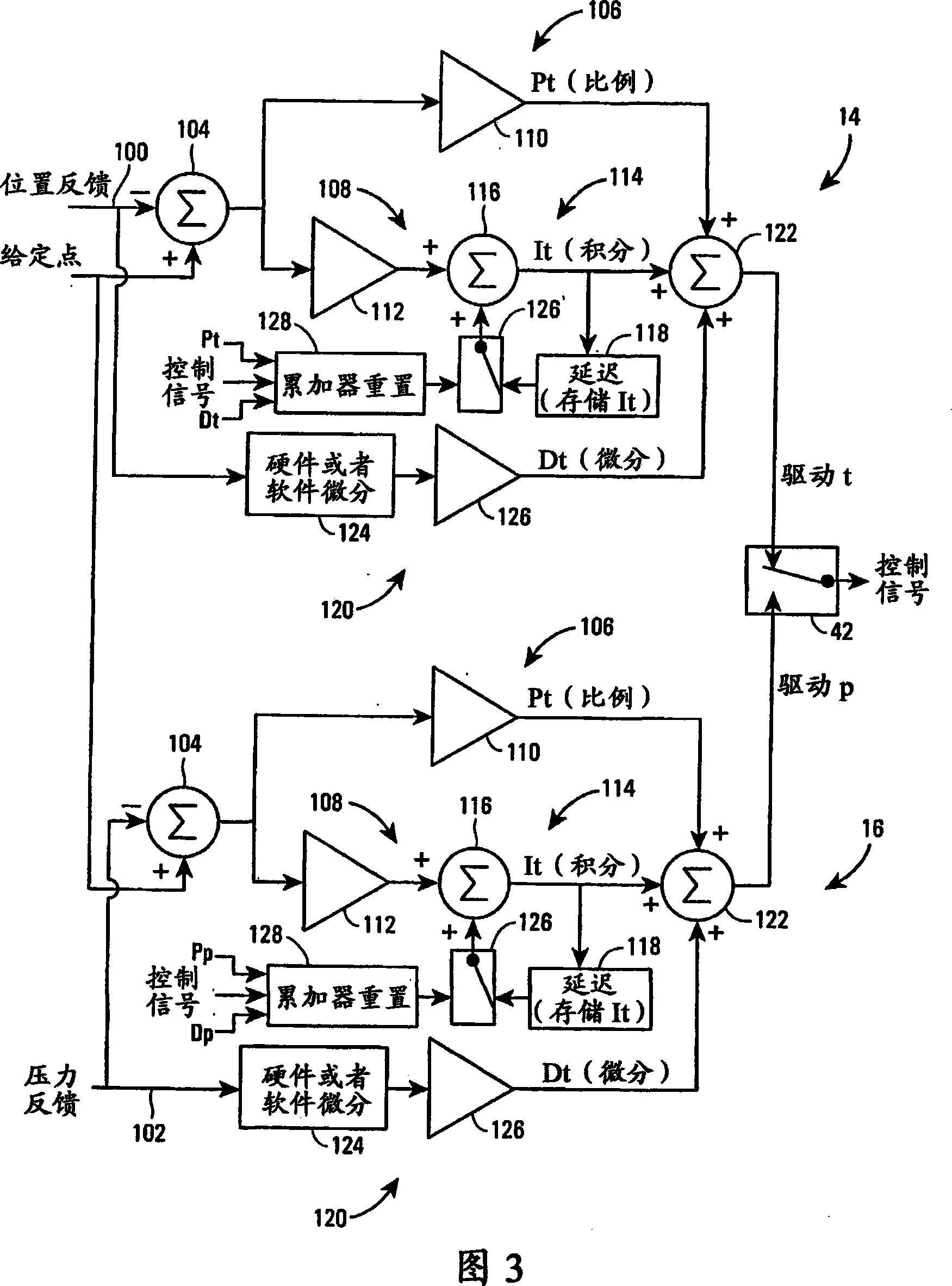

[0029] The disclosed controllers and methods generally relate to feedback control mechanisms for process control devices, such as valves. Although the disclosed controllers and methods are described in detail in connection with pneumatically actuated valves, the disclosed controllers and methods are suitable for use with or implemented with otherwise actuated valves, as well as process control devices other than valves. Accordingly, the disclosed controllers and methods can be used or implemented in conjunction with any device in a process control network, and are particularly suitable for applications having two or more possible feedback mechanisms available as controls device of. While it is also possible to use the disclosed controllers and methods in conjunction with two feedback controls of the same or similar types, the exemplary embodiments described herein present controllers in the context of switching feedback control between two different control mechanisms. and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com