Method for creating three-dimensional finite element mesh

A finite element and mesh technology, applied in the field of generating 3D finite element meshes, can solve the problems of complex hexahedral mesh process, 3D mesh modeling taking a lot of time, and difficulty in the field of engineering design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and specific embodiments.

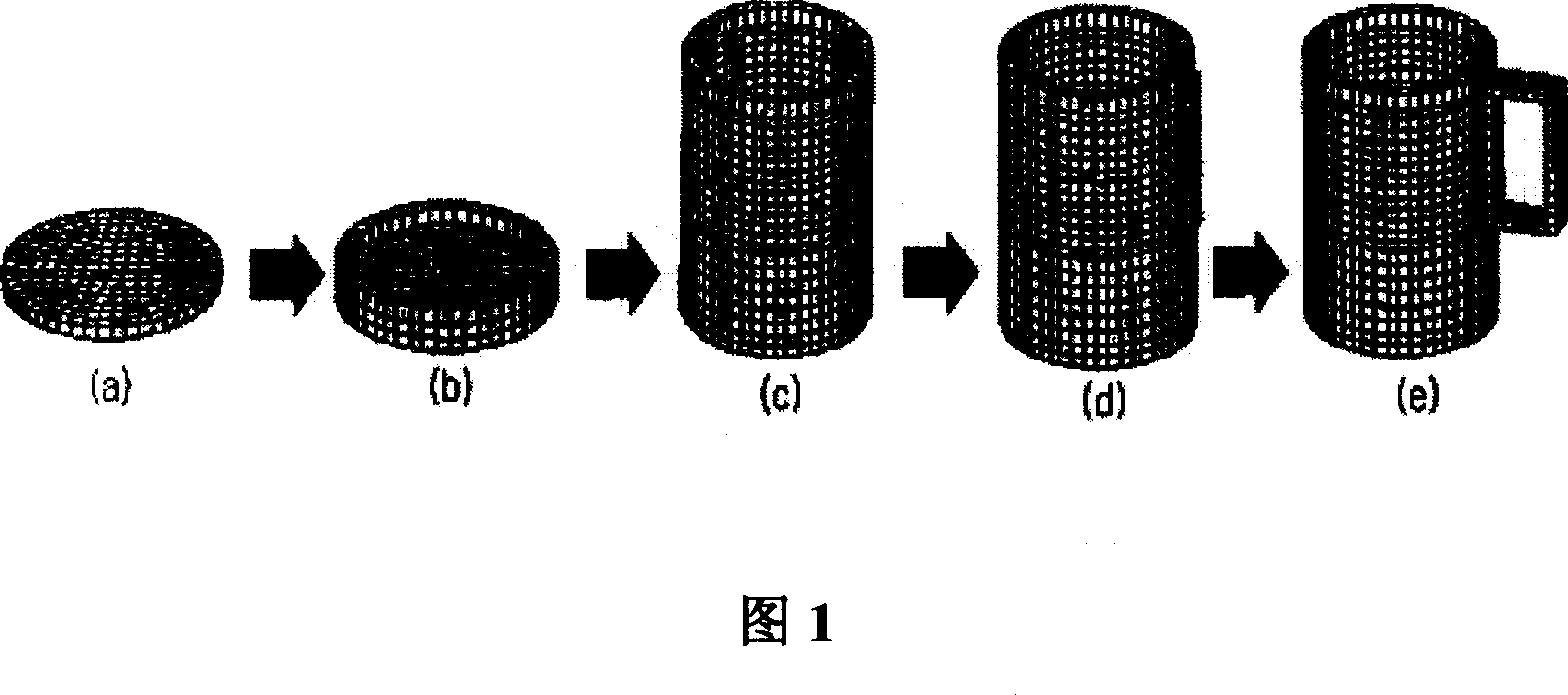

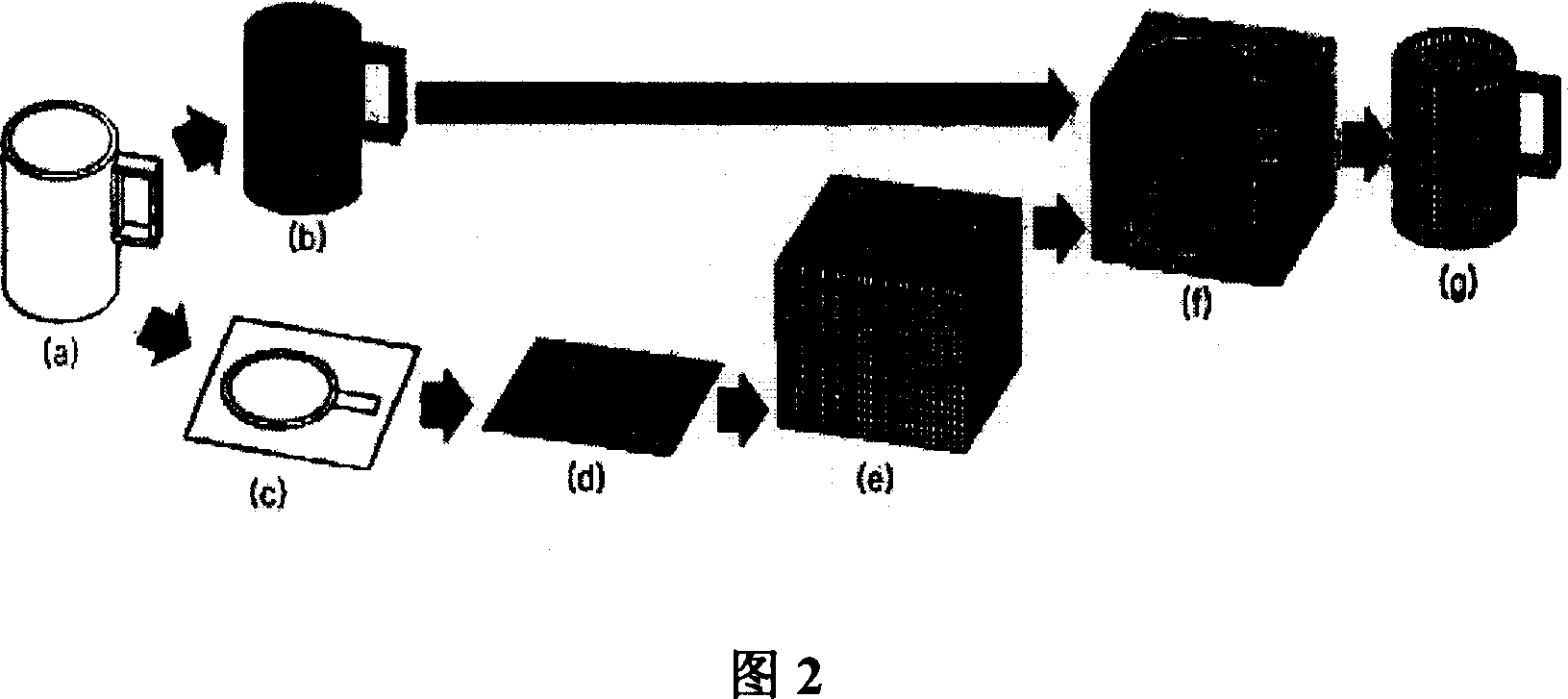

[0034] As shown in Figure 2 and Figure 3a to Figure 3e, a three-dimensional finite element mesh generation process of a cup is taken as an example. For the entity of a cup, as shown in Figure 2a, a three-dimensional model of it needs to be established first, which can be established by CAD modeling software. The second step is to create a grid on the surface of the cup. Use the CAD model of the cup to build the surface mesh, as shown in Figure 2b and Figure 3a. The generation method of the surface mesh is the traditional meshing method, and its basic principle is to obtain the corresponding surface mesh through node connection. For engineering analysts, it can be implemented very easily. The third step is to draw the projection contour line of the cup CAD model, as shown in Figure 2c and Figure 3b, and project the cup vertically onto the horizontal plane where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com