Shift binding device of manual speed-changer

A technology of manual transmission and combination device, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of abnormal noise, tooth knocking, loud noise, etc., and achieve long service life, reliable connection, and high security. coaxial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

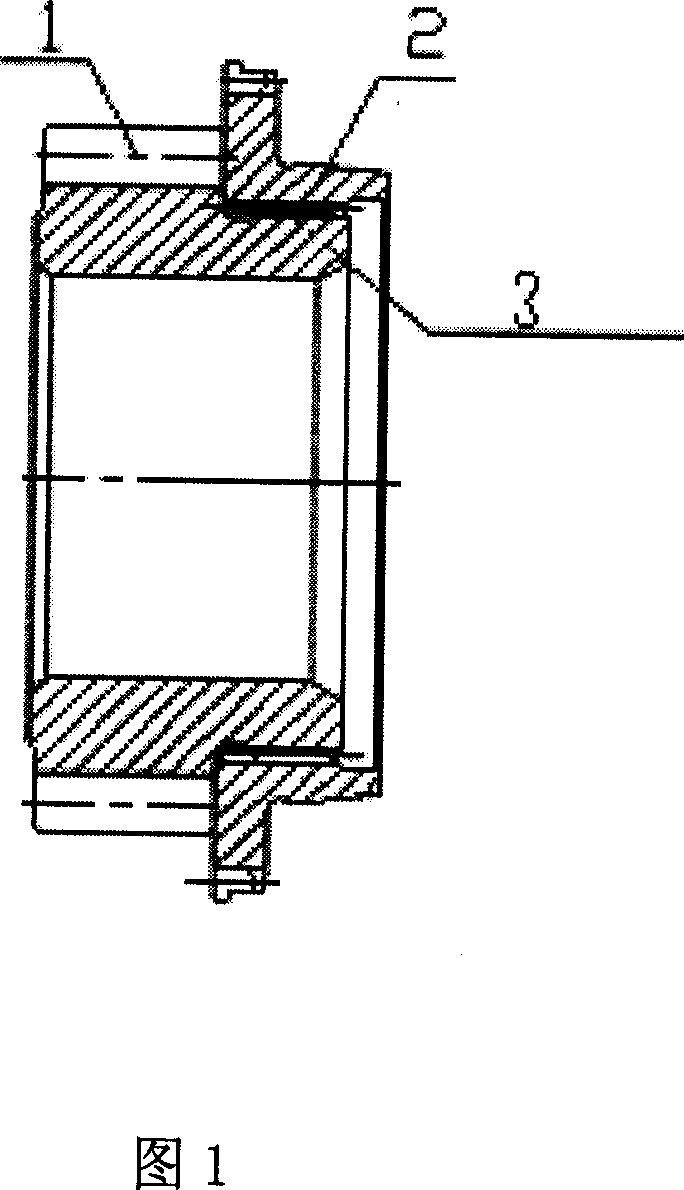

[0011] In Fig. 1, the helical gear 1 is connected with the synchronous cone through the involute spline 3, the connection adopts the involute spline 3, in the involute spline 3, the number of teeth Z=52, the modulus m =1, pressure angle α=30, and uniform distribution. The spline has good manufacturability, can be processed by the generating method, has high production efficiency, high processing precision and low cost.

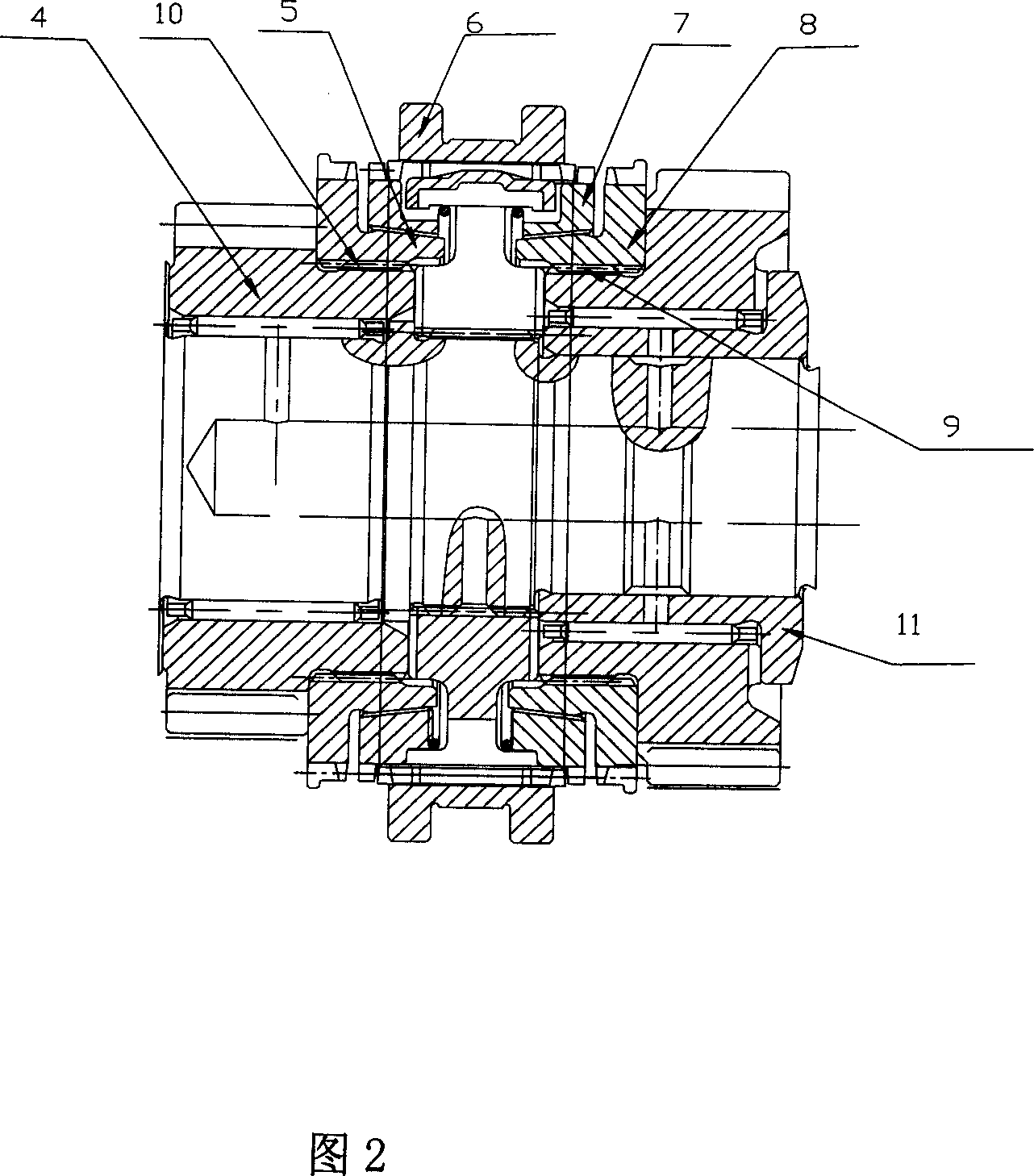

[0012] In Fig. 2, the third-gear active helical gear 4 is connected to the input shaft, and the other side of the third-gear active helical gear 4 is connected to the third-gear synchronous cone 5 through the third-gear spline 10, and the third-gear synchronous cone 5 is connected to the third and fourth gears. The gear shift is combined with the gear sleeve 6. Three, four gear shifts are connected with the fourth gear synchronous cone 7 in combination with the tooth cover 6 other side. The fourth gear synchronous cone 7 is connected with the fourth gear dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com