Single-column type automobile engine body

An automobile engine, single-row technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of cylinder liner hole ellipticity increase, cylinder liner hole out of round, affecting engine performance and reliability, etc., to achieve processing Easier, prevents blow-by, and improves cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

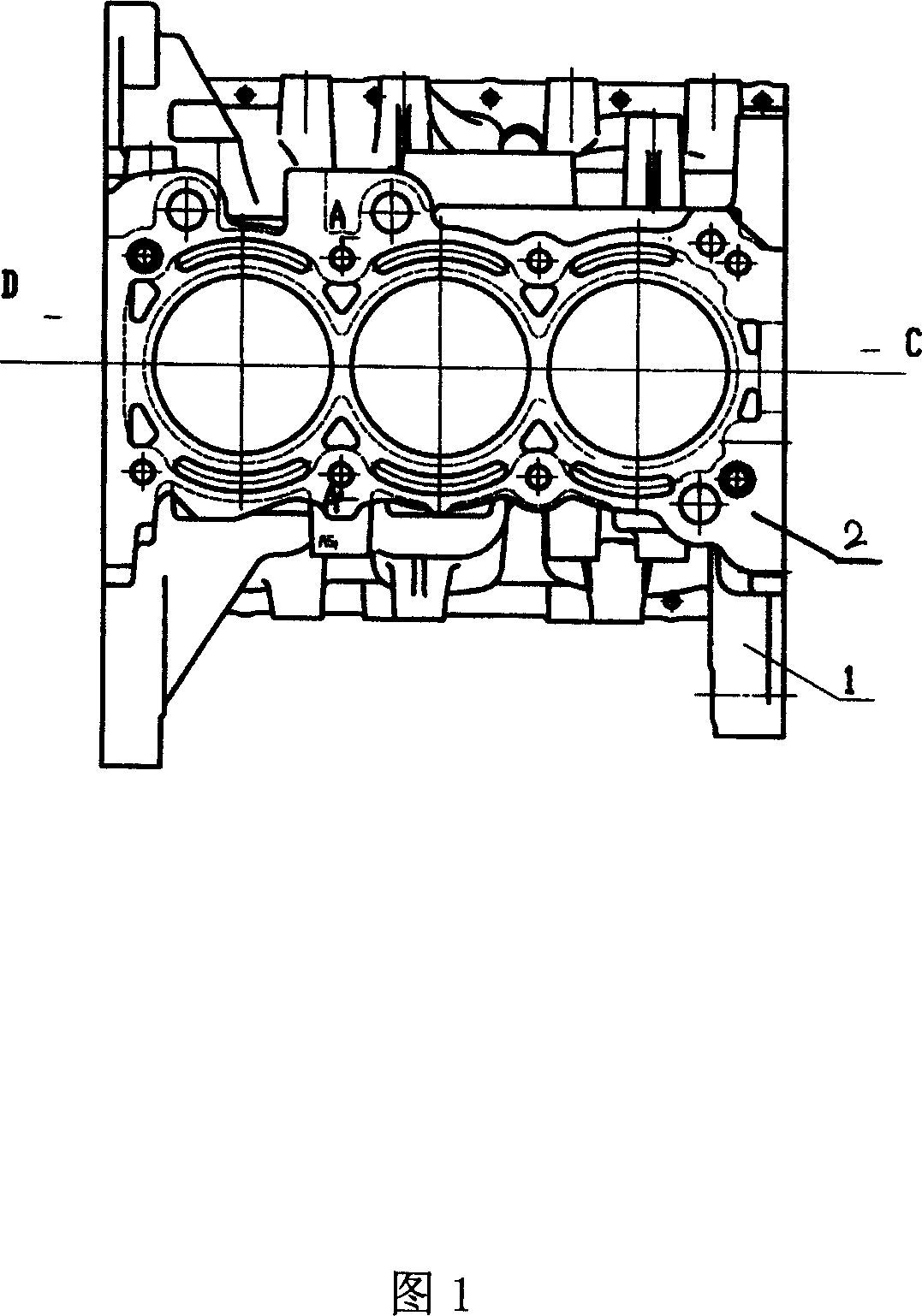

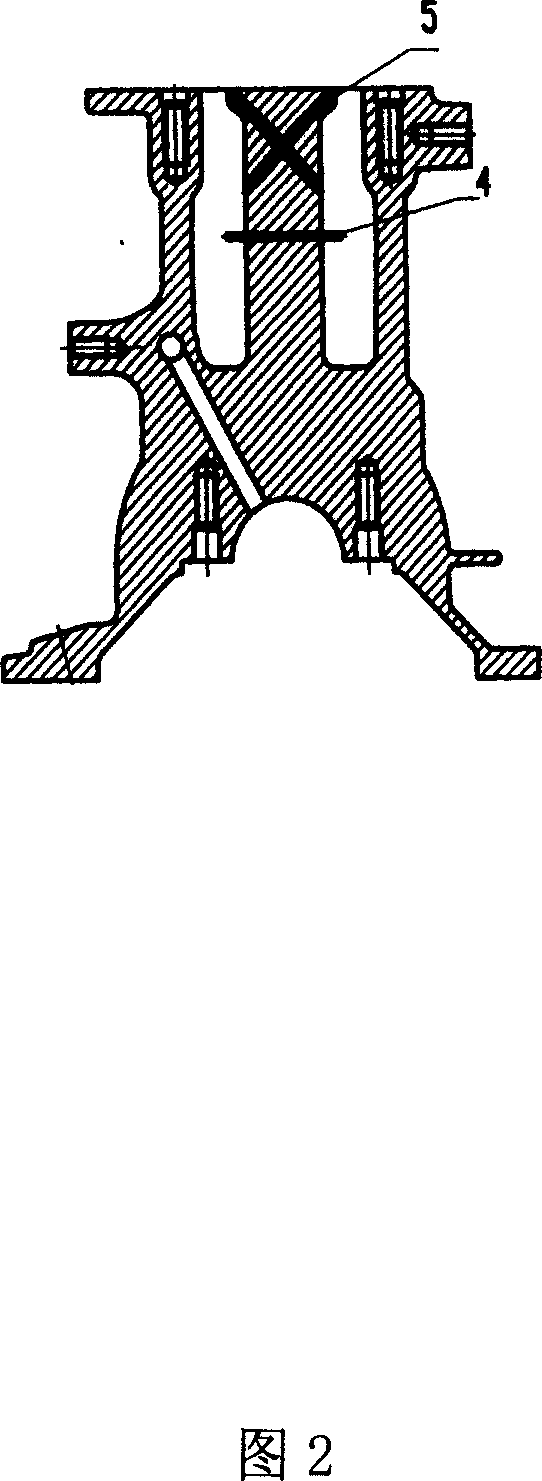

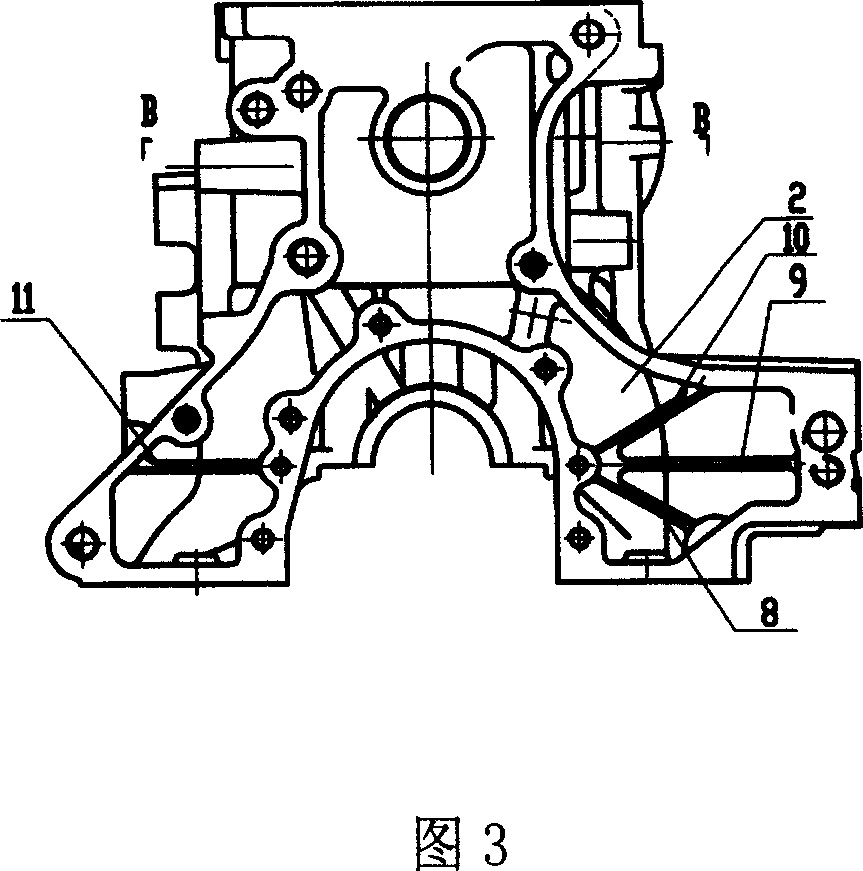

[0013] In conjunction with Fig. 1 and Fig. 2, a single-row automobile engine body is composed of a cast crankcase 2 and a cylinder block 1. There is a water trap outside the hole wall, and the centerlines of the cylinder bores are located in the same plane. The distance between the walls of the cylinder 3 provided on the cylinder block 1 is 8 mm, and the distance between the cylinder centers / bore diameter is L 0 / D=1.11. In this embodiment, the design of the water jacket between two adjacent cylinders is abandoned. In the water interlayer, within 60mm below the top surface of the body, support columns are symmetrically arranged on both sides of the plane where the center line of the cylinder liner hole is located. ; For the convenience of casting production, a mud core support 4 is provided in the interval between two adjacent cylinders 3 (refer to Figure 2). In order to solve the problem of enhanced cooling of the engine, intersecting cooling water holes 6 (refer to FIG. 2 )...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap