Feeding and carding system for hackling machine

A carding machine and carding technology, applied in fiber processing, textiles and papermaking, deburring devices, etc., can solve the problems of severe fiber tearing and fracture, carding machine crash, damage to carding equipment, etc., and achieve light fiber tearing and fracture , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

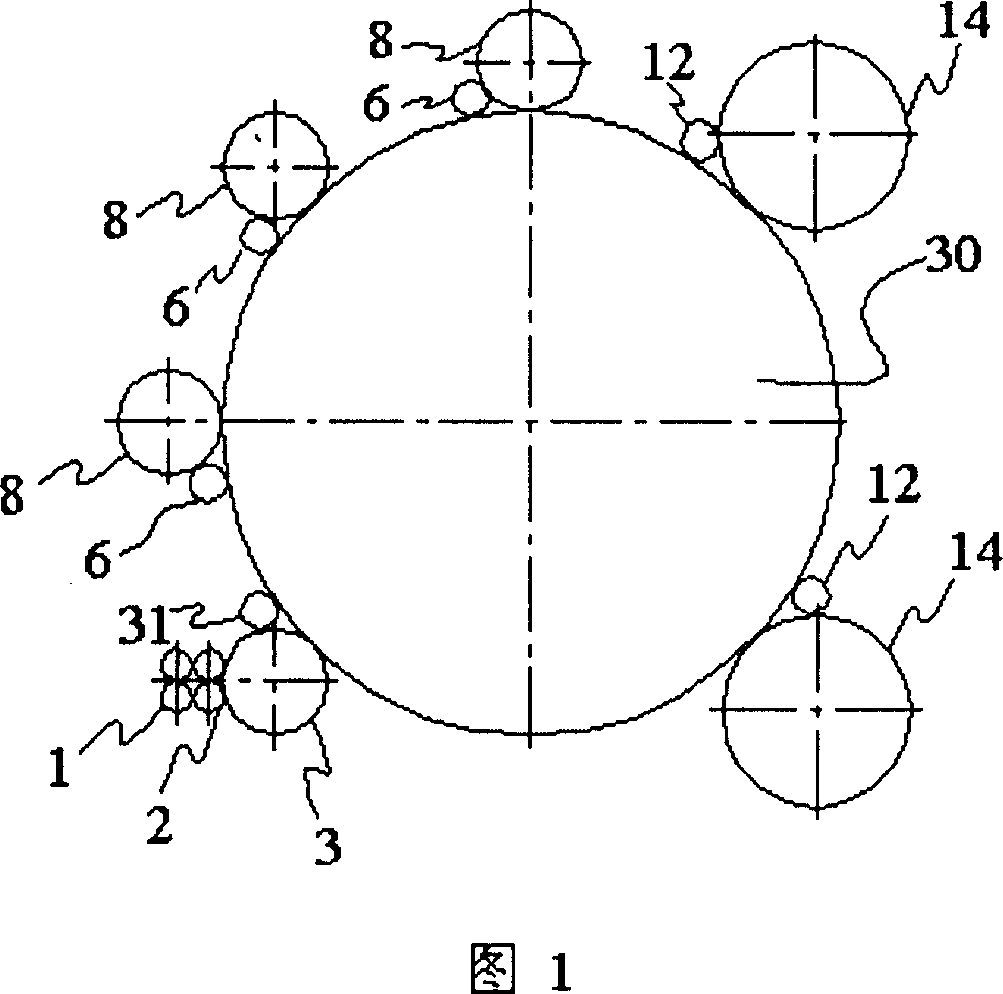

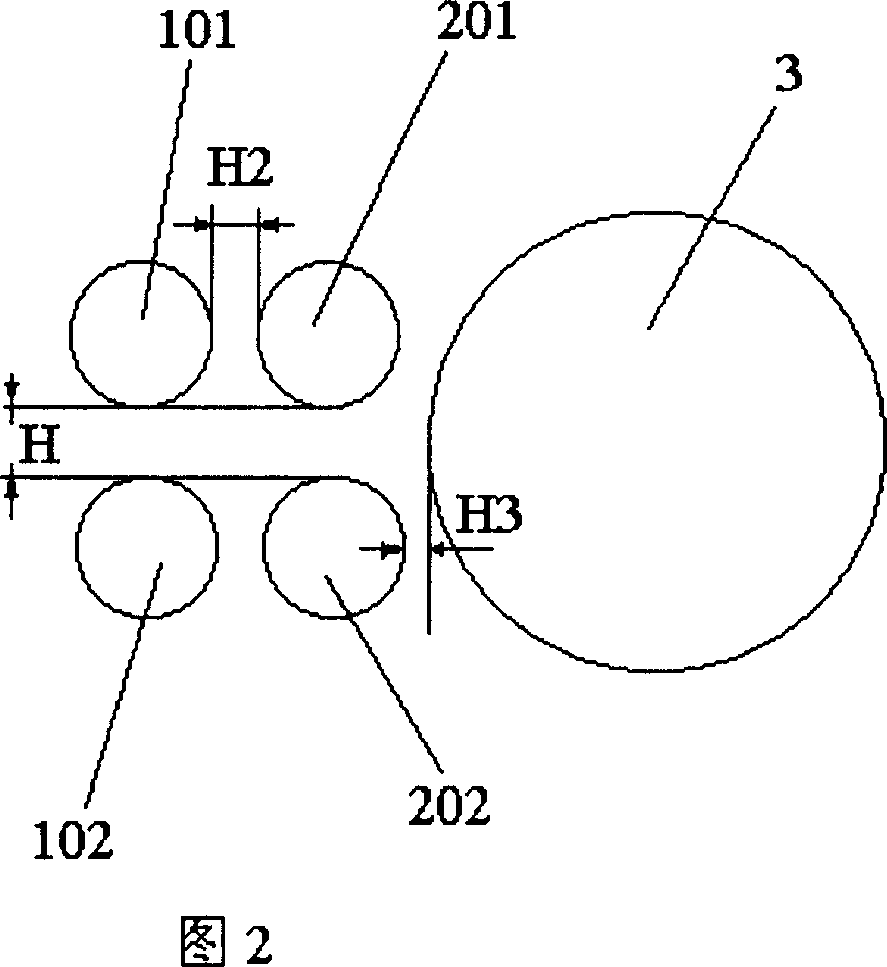

[0032] The length of the feeding main fiber is 300mm, the weight ratio of the composite fiber to the reinforcing fiber is 55:45, two pairs of feeding rollers are used in the fiber feeding system, the distance between the upper and lower rollers is 60mm, the distance between the primary and secondary pairs of feeding rollers is 55mm, and the diameter of the rollers is The diameter of the licker-in roller is 88mm, the diameter of the licker-in roller is 305mm, the diameter of the working roller is 210mm, the diameter of the stripping roller is 125mm, 4 sets of carding areas, the height of the metal wires of the feeding roller, working roller, stripping roller, cylinder, and doffer They are 6mm, 4mm, 3.3mm, 3.2mm, 4mm respectively, and the longitudinal pitches of the pins are 7.6mm, 2.5mm, 3.2mm, 3.2mm, 2.5mm respectively. The metal card clothing of the licker-in roller adopts straight teeth.

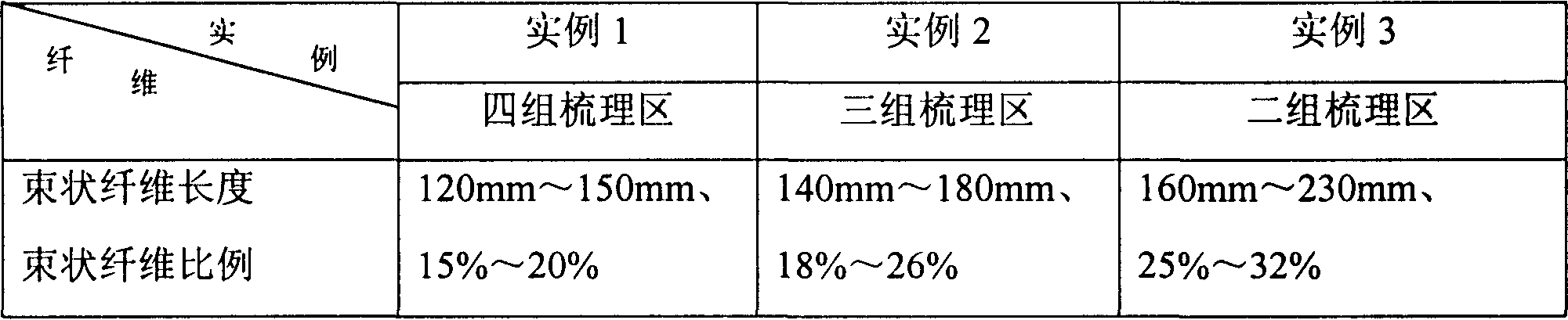

[0033] The bundled fiber length after carding is 120 mm to 150 mm, and the bundled fibe...

Embodiment 2

[0035] Repeat the process of Example 1, feed the main fiber length 300mm, the ratio of composite fiber to reinforcing fiber is 55:45, adopt two pairs of feeding rollers in the fiber feeding system, the distance between the upper and lower rollers is 65mm, and the distance between the primary and secondary pairs of feeding rollers 100mm, diameter of roller is 110mm, diameter of licker-in roller is 305mm, diameter of working roller and stripping roller of carding machine is 210mm and 125mm respectively, 3 sets of carding areas, metal clothing for roller, working roller, stripping roller, cylinder and doffer The needle heights of the needles are 6mm, 4.0mm, 3.3mm, 3.2mm, 4mm, the longitudinal pitches of the needles are 7.6mm, 2.5mm, 3.2mm, 3.2mm, 2.5mm, and the metal clothing of the licker-in roller adopts straight teeth . After carding, the bundled fiber length is 140 mm to 180 mm, and the bundled fiber ratio is 15% to 20% (see Table 1).

Embodiment 3

[0037] Repeat the process of Example 1, feed the main fiber length 300mm, the ratio of composite fiber and reinforcing fiber is 55:45, adopt two pairs of feeding rollers in the fiber feeding system, the distance between the upper and lower rollers is 20mm, and the distance between the two pairs of feeding rollers is 50mm. The diameter of the roller is 110mm, the diameter of the licker-in roller is 305mm, the diameters of the working roller and the depilling roller of the carding machine are 210mm and 125mm respectively, 2 sets of carding areas, metal clothing for the feeding roller, working roller, depilling roller, cylinder and doffer The needle heights of the needles are 6mm, 4mm, 3.3mm, 3.2mm, 4mm, the longitudinal pitches of the needles are 7.6mm, 2.5mm, 3.2mm, 3.2mm, 2.5mm, and the metal clothing of the licker-in roller adopts straight teeth. After carding, the bundled fiber length is 120 mm to 150 mm, and the bundled fiber ratio is 15% to 20% (see Table 1).

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com