Cylinder battery casing laser welding fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

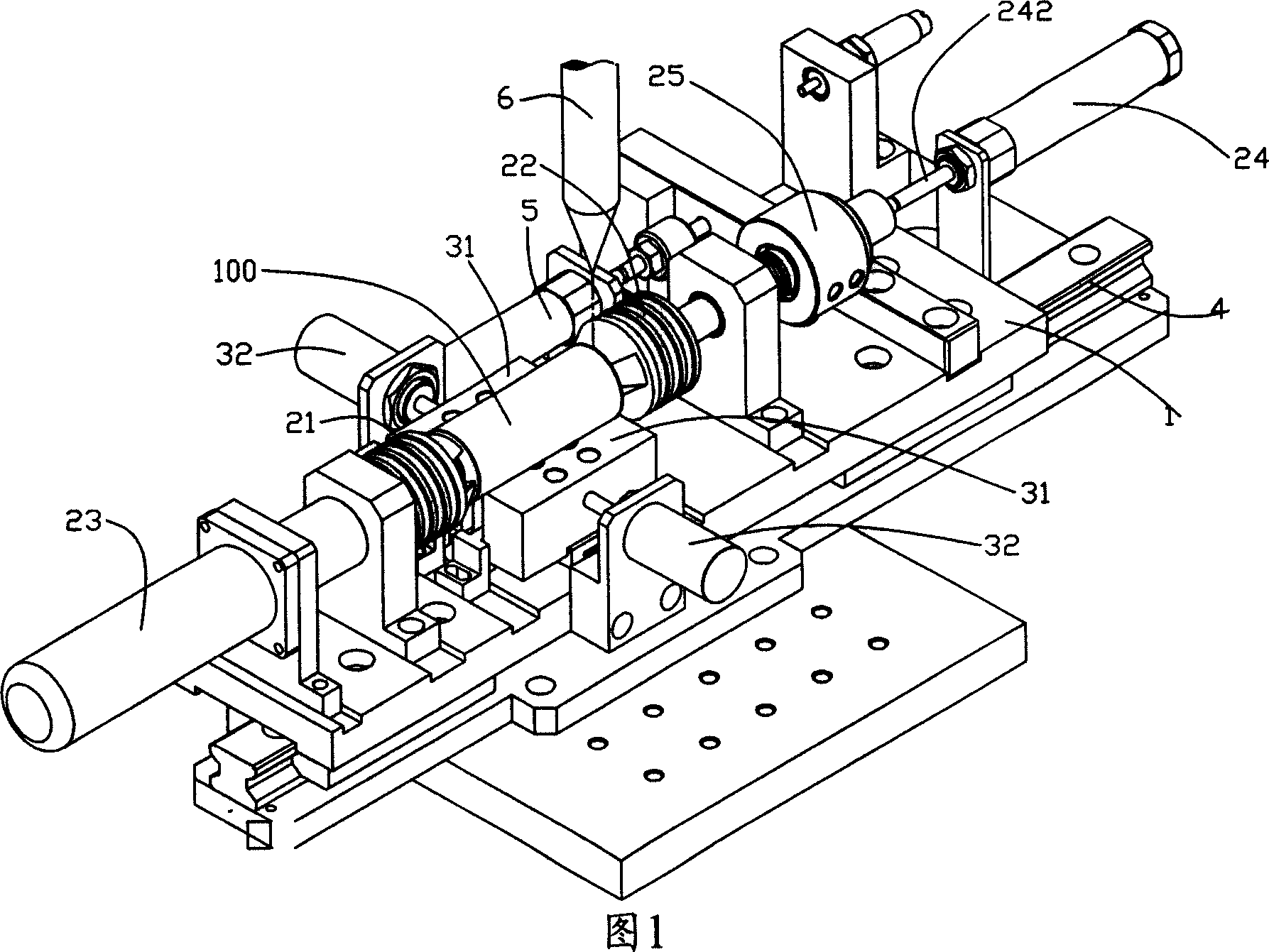

[0021] Please refer to FIG. 1 , which is a preferred embodiment of the present invention. The cylindrical battery casing laser welding jig mainly includes a workbench 1 , a clamping mechanism and a supporting mechanism.

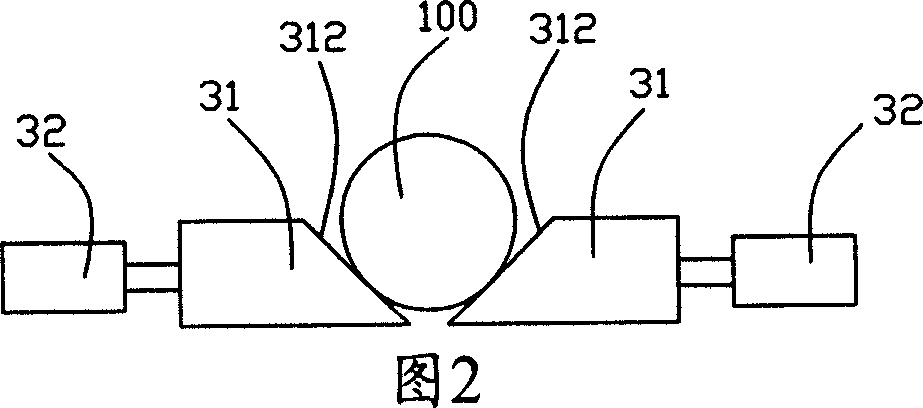

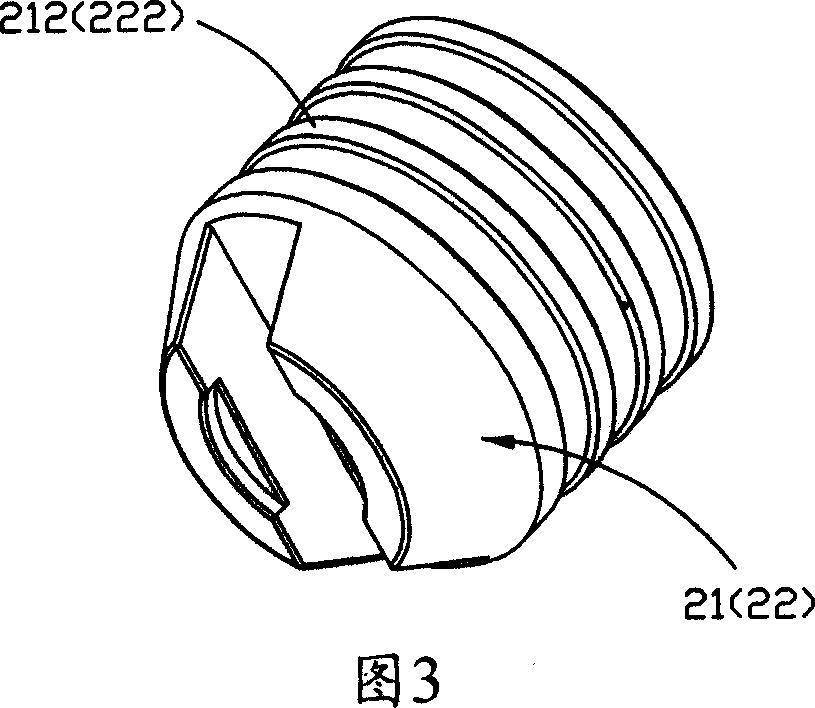

[0022] The clamping mechanism is located on the workbench 1 and includes two chucks 21 , 22 , a first driving device 23 and a second driving device 24 . The two clamps 21 and 22 are used to clamp both ends of the battery 100 , one clamp 21 is connected to the first driving device 23 , and the other clamp 22 is connected to the second driving device 24 . The first driving device 23 is used to drive the chucks 21 and 22 to rotate around their own axis as the rotation axis. In this embodiment, the first driving device 23 is a servo motor. This second driving device 24 is used to drive chuck 22 close to or away from another chuck 21, in the present embodiment, second driving device 24 is an air cylinder, its piston rod 242 and the mounting handle of chuck 22 (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com