Gas-barrier nanocomposite composition and article using the same

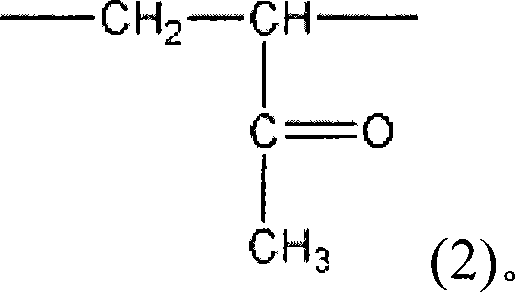

A nano-composite material and composition technology, which is applied in the field of nano-composite material compositions with excellent impermeability and plasticity, can solve problems such as unsatisfactory impermeability, and achieve excellent mechanical strength, excellent oxygen, and impermeability. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The materials used in the following examples are as follows:

[0064] EVOH: E105B (Kuraray, Japan)

[0065] Amorphous nylon: SELAR 2072 (DuPont, USA)

[0066] Nylon 6, 12: Zytel 158L (DuPont, USA)

[0067] Nylon 6: EN 500 (KP Chemical)

[0068] HDPE-g-MAH: Compatibilizer, PB3009 (CRAMPTON)

[0069] HDPE: ME6000 (LG Chem)

[0070] Ionomer: SURLYN 8527 (DuPont, USA)

[0071] Clay: Closite 30B (SCP)

[0072] Heat stabilizer: IR 1098 (Songwon Co., Ltd.)

preparation Embodiment 1

[0074] (Preparation of EVOH / intercalated clay nanocomposites)

[0075] 97wt% ethylene-vinyl alcohol copolymer (EVOH; E-105B (ethylene content: 44mol%); Kuraray, Japan; melt index: 5.5g / 10min; density: 1.14g / cm 3 ) into the main hopper of a twin-screw extruder (SM Platek co-rotating twin-screw extruder; 40). Then, 3 wt% of organomontmorillonite (Southern IntercalatedClay Products, U.S.; C2OA) as intercalation clay and 0.1 wt. parts of IR as heat stabilizer based on a total of 100 wt. 1098 were placed into the side feeder of a twin-screw extruder to prepare sheet-shaped EVOH / intercalated clay nanocomposites. The extrusion temperature conditions were 180-190-200-200-200-200-200° C., the screw was rotated at 300 rpm, and the discharge conditions were 15 kg / hr.

preparation Embodiment 2

[0077] (Preparation of nylon 6 / intercalated clay nanocomposites)

[0078] 97 wt% polyamide (Nylon 6) was charged into the main hopper of a twin-screw extruder (SM Platek co-rotating twin-screw extruder; φ40). Then, 3 wt% of organomontmorillonite as intercalation clay and 0.1 part by weight of IR 1098 as heat stabilizer based on a total of 100 parts by weight of polyamide and organomontmorillonite were put into the twin-screw extruder respectively. Side feeder to prepare sheet-shaped nylon 6 / intercalated clay nanocomposites. The extrusion temperature conditions were 220-225-245-245-245-245-245°C, the screw was rotated at 300 rpm, and the discharge conditions were 40 kg / hr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com