Improvement for packing image sensing chip construction oncircuit board

A technology of image sensing and packaging methods, which is applied in the direction of circuits, color TV parts, TV system parts, etc., can solve problems such as the decline of good rate, the decline of product good rate, and the loss of foundries, so as to reduce the packaging process cost, the effect of reducing packaging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

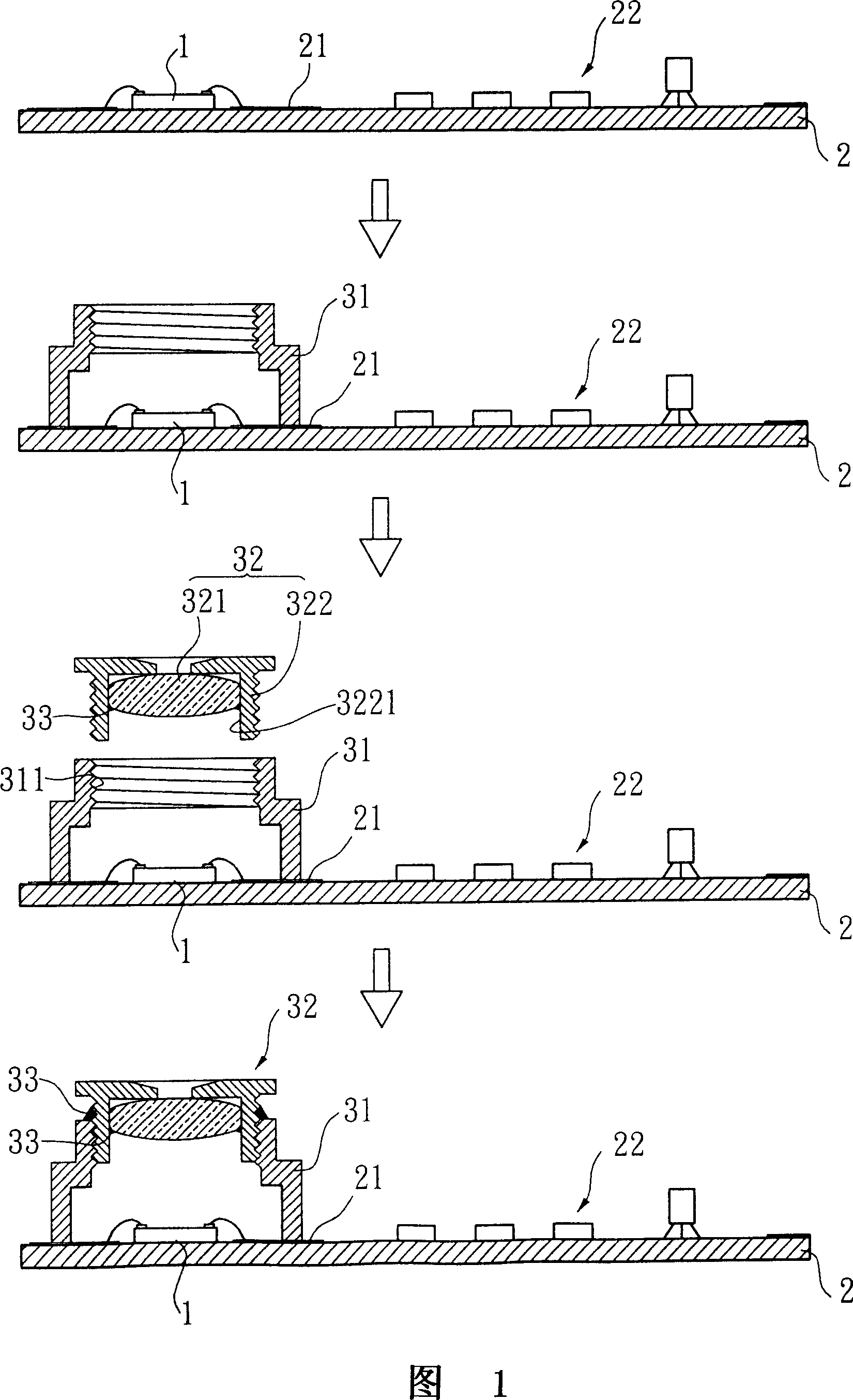

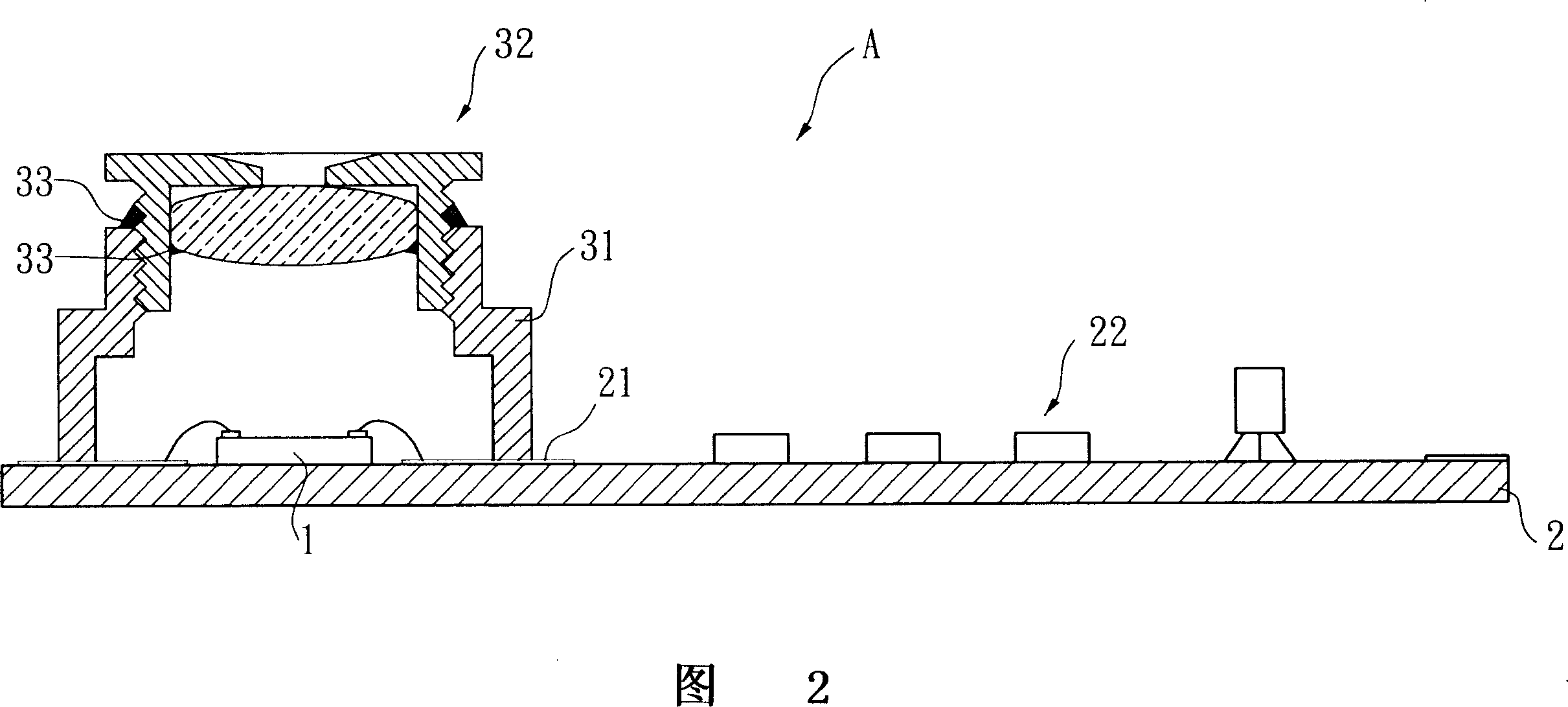

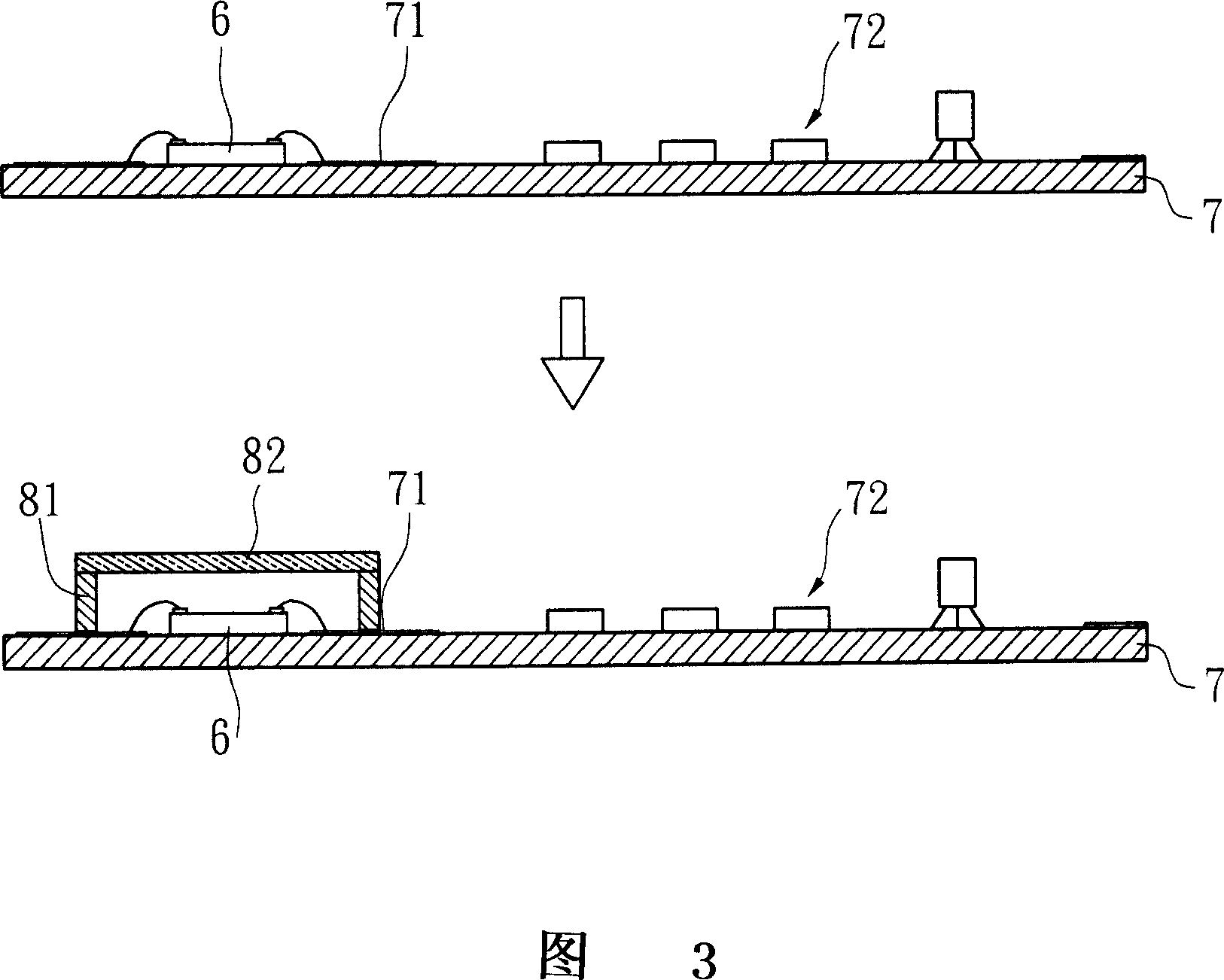

[0018] As shown in Fig. 1 and Fig. 2, the packaging method for improving the structure of the image sensor chip on the circuit board disclosed by the present invention includes the following steps:

[0019] First provide a module circuit substrate 2 with several pins 21 and module circuits 22 on the surface, and install an image sensing chip 1 on it, and wire from the image sensing chip 1 to each pin 21 to form an electrical circuit board. sexual connection.

[0020] A lens holder 31 is provided, and the lens holder 31 corresponds to the position of the image sensing chip 1 .

[0021] One or more lenses 321 are assembled into a slotted hole 3221 formed axially inside a cylindrical frame 322, and the gap between the periphery of the lens 321 and the wall of the slotted hole 3221 is filled with adhesive material 33 to seal the two to form a lens Assembly 32 , then, assemble the lens assembly 32 into the threaded hole 311 on the upper end of the lens mount 31 , so that the lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com