A large-size photomultiplier tube waterproof packaging structure and packaging method

A photomultiplier tube and packaging structure technology, applied in electron multiplier tubes, discharge tubes, circuits, etc., can solve the problems of inability to upgrade PMT, rely on manual processes, increase costs, etc., achieve simple and reliable packaging structure, low operator requirements, Realize the effect of replacement and upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

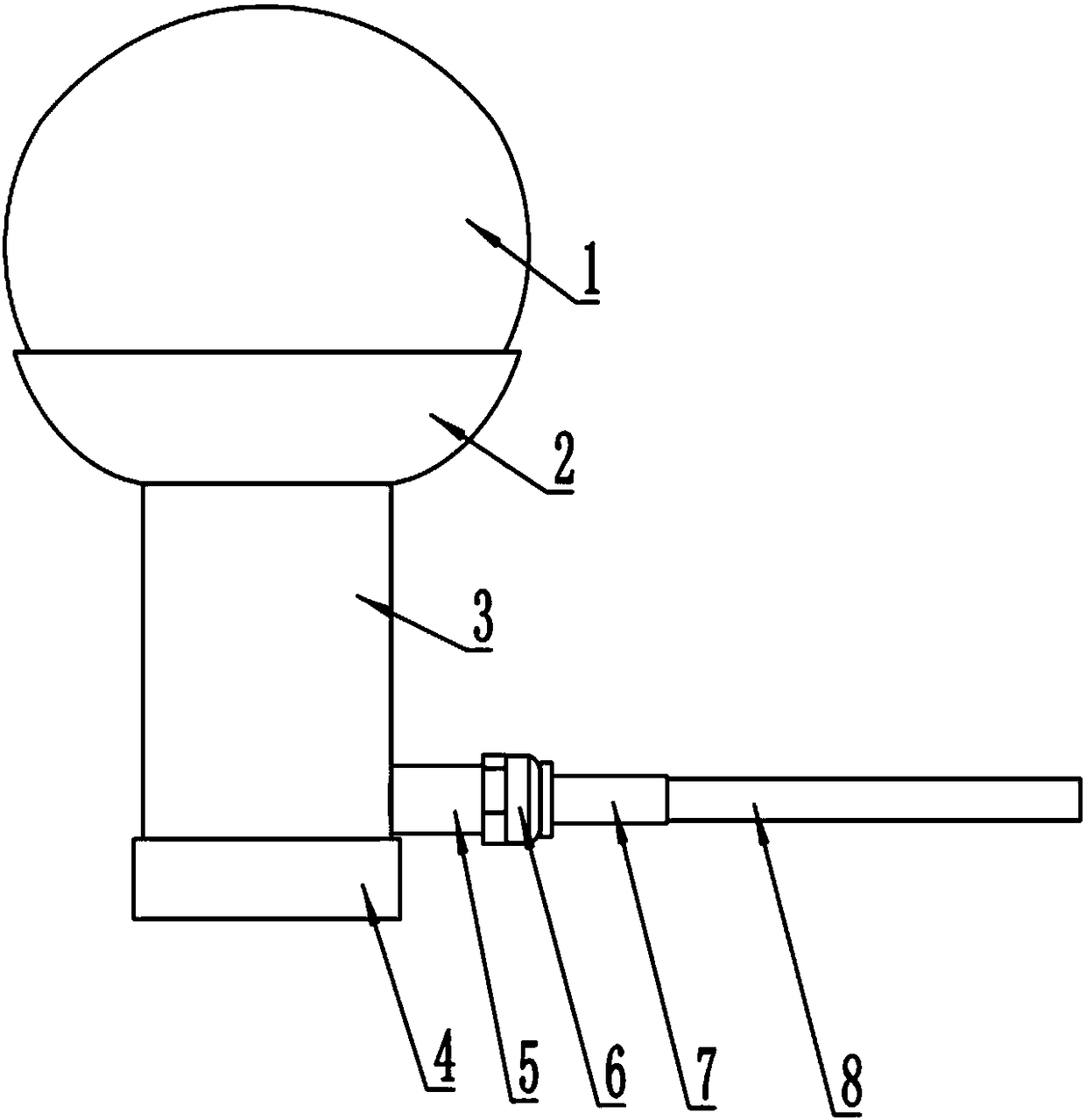

[0038] Such as figure 1 As shown, a large-size photomultiplier tube waterproof packaging structure, including stainless steel tray 2, stainless steel sleeve 3, stainless steel bottom cover 4, stainless steel cable joint base 5, stainless steel cable joint lock nut 6, stainless steel cable joint sleeve 7. The stainless steel tray 2 and the stainless steel sleeve 3 are connected by full welding, and the exterior is polished; the stainless steel sleeve 3 and the stainless steel bottom cover 4 are connected by threads; the stainless steel sleeve 3 and the stainless steel cable joint base 5 are connected by full welding; the stainless steel cable joint base 5 and the stainless steel cable joint lock nut 6 are threadedly connected; the stainless steel cable joint lock nut and the stainless steel cable joint sleeve 7 are connected by full welding.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com