Ultrasonic inspection of petroleum pipeline and inspecting robot

A technology of oil pipelines and detection methods, which is applied in the field of robots, can solve the problems of low energy consumption, and achieve the effects of low energy consumption, simple structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

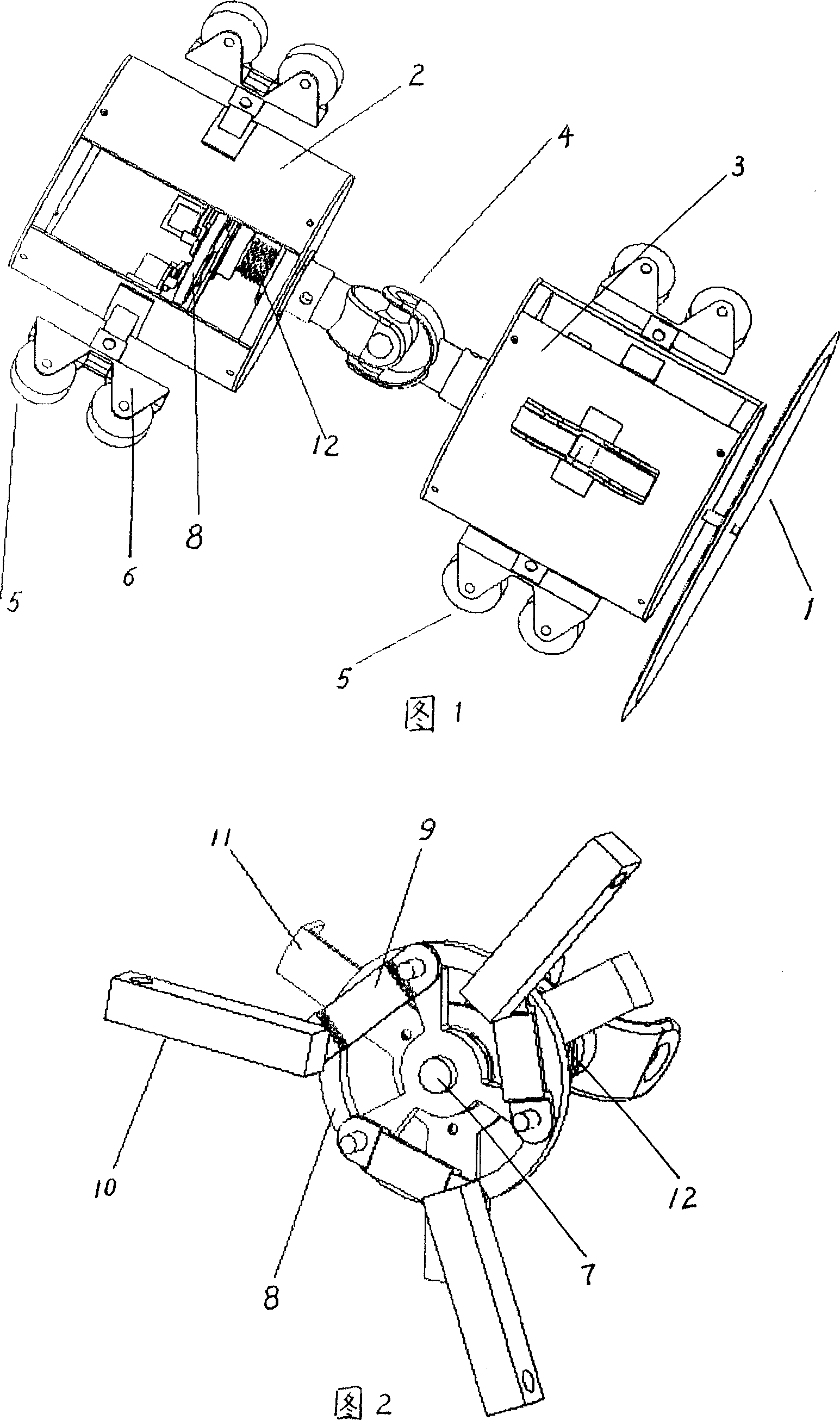

[0021] As shown in Figures 1 and 2, the present invention provides a method for ultrasonic detection of oil pipelines and a robot for detection. The robot adopts a driven structure. The robot is composed of a fuselage, a traveling mechanism and a detection device. The detection device is an ultrasonic probe. Contains ultrasonic transmitter and receiver, installed on the front end of the robot body, characterized in that: there is a rubber disc 1 at the tail of the robot, the body is composed of two cylinders, divided into two parts, the front part 2 and the rear part 3, the body The front part 2 and the rear part 3 are connected by a universal joint 4; the traveling mechanism is a driven wheel, which is respectively installed on the front part and the rear part of the fuselage; the detection device is installed on the front fuselage.

[0022] The traveling mechanism is six groups of driven wheels, two wheels 5 are a group, and each group of wheels differs by 120 degrees, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com