Auxiliary air-inlet atomizing power increaser of engine

An engine and power technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as inconvenient operation and use, poor ratio mixing, difficult control and adjustment, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

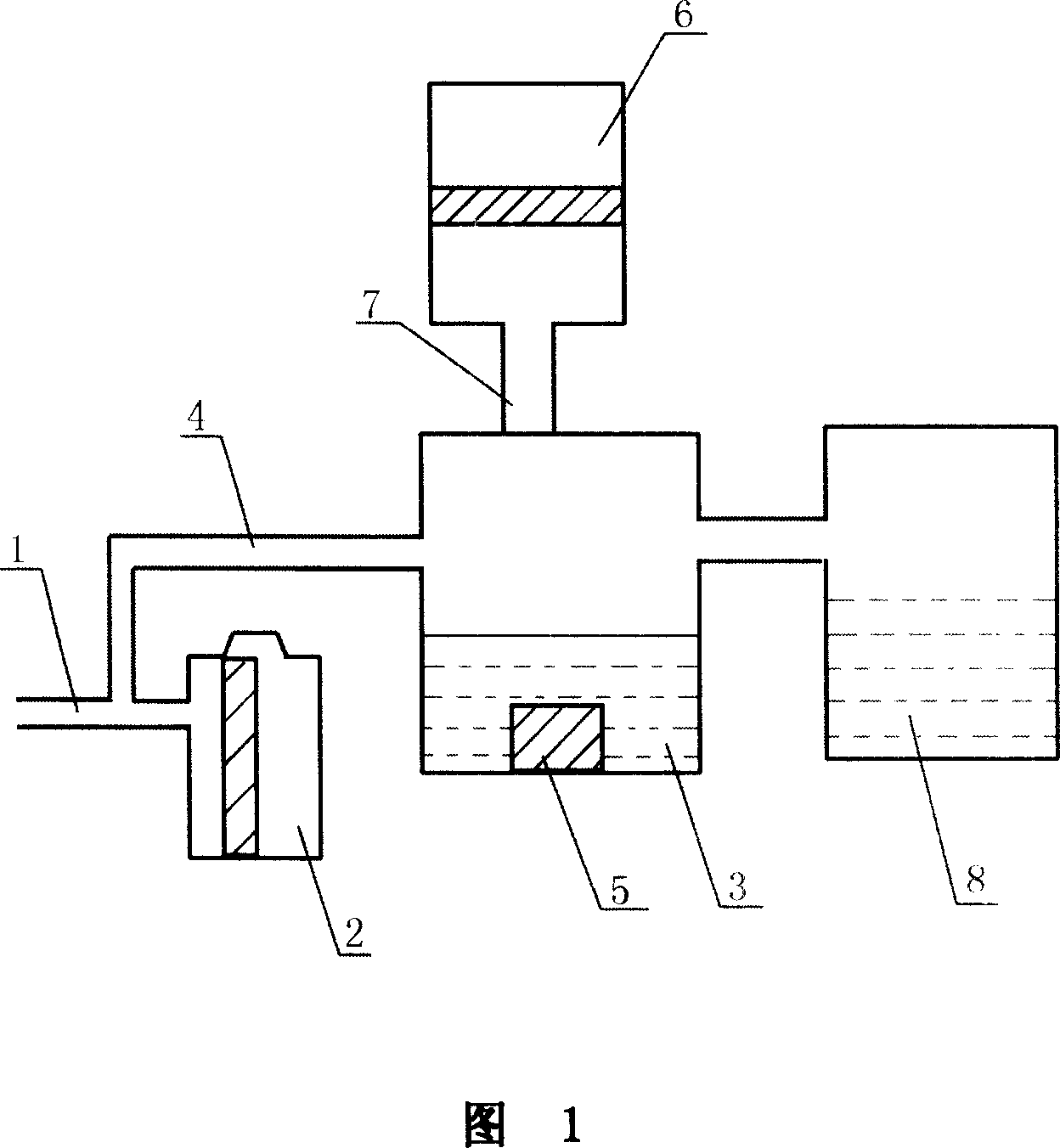

[0008] The present invention adopts the following structure: an engine air intake auxiliary atomization power increasing device, including an engine air path 1, an air filter 2 is arranged on the engine air path 1, and an atomizing cylinder 3 connects with the engine air through an atomizing suction conduit 4. 1 is connected, and the atomizer 5 is arranged in the atomizing cylinder 3, and the atomizing cylinder 3 is connected with the auxiliary air filter 6 through the connecting pipe 7. The atomizing cylinder 3 is connected with an automatic water replenishment device 8 .

[0009] When the device is in use, the air filtered by the auxiliary air filter 6 enters the atomizing cylinder 3 through the connecting pipe 7, and after being mixed with the atomized water produced by the atomizer 5 in the atomizing cylinder 3, it is discharged at the inlet of the engine. Under the action of negative air pressure, it is naturally inhaled into the cylinder through the atomization suction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com