Method for adhesion of film and apparatus thereof

A film sticking and thin film technology, which is applied in lamination devices, chemical instruments and methods, thin material processing, etc., can solve the problems of lower yield, difficulty in sticking films, and lower image quality, and achieve reliable sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

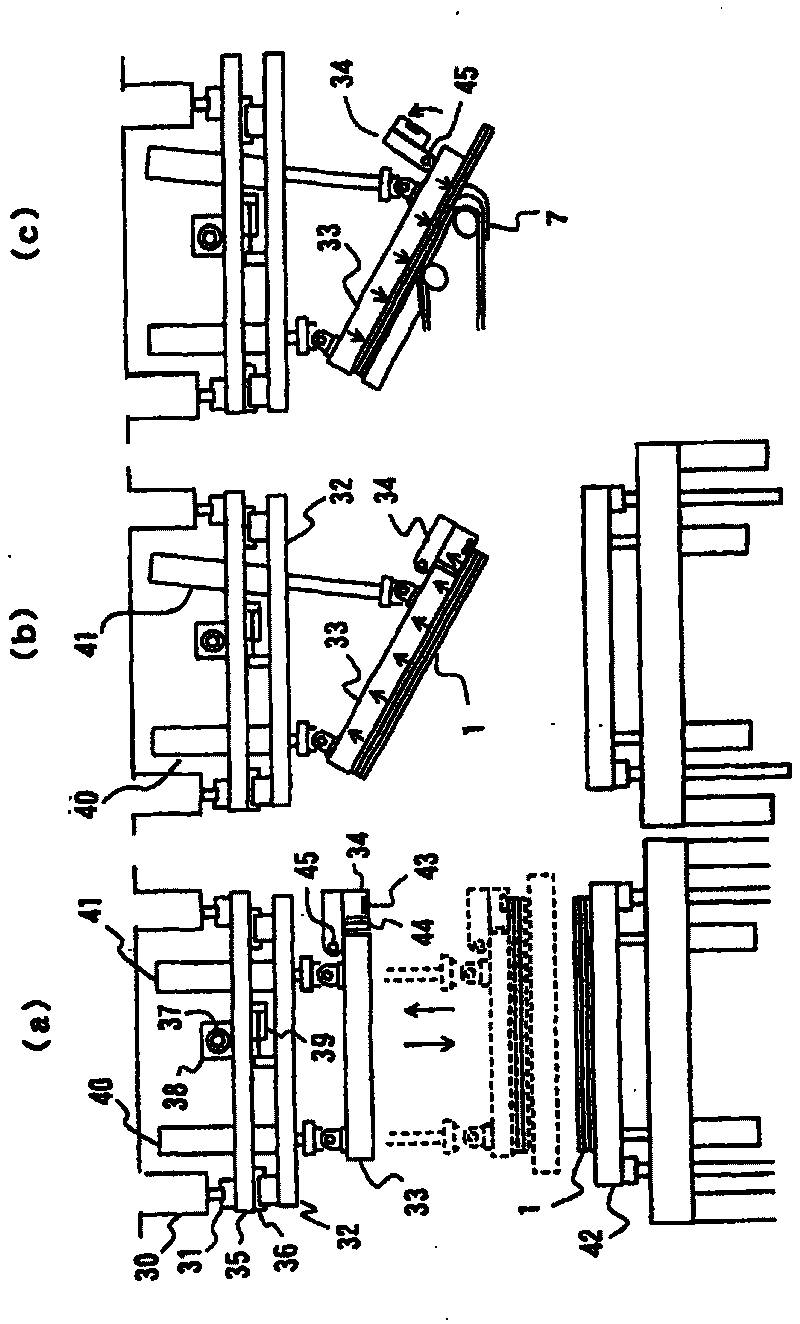

[0029] Refer to the following Figure 1 to Figure 9 , an embodiment of the present invention will be specifically described. In addition, the same reference symbols are used for the same components in all the drawings.

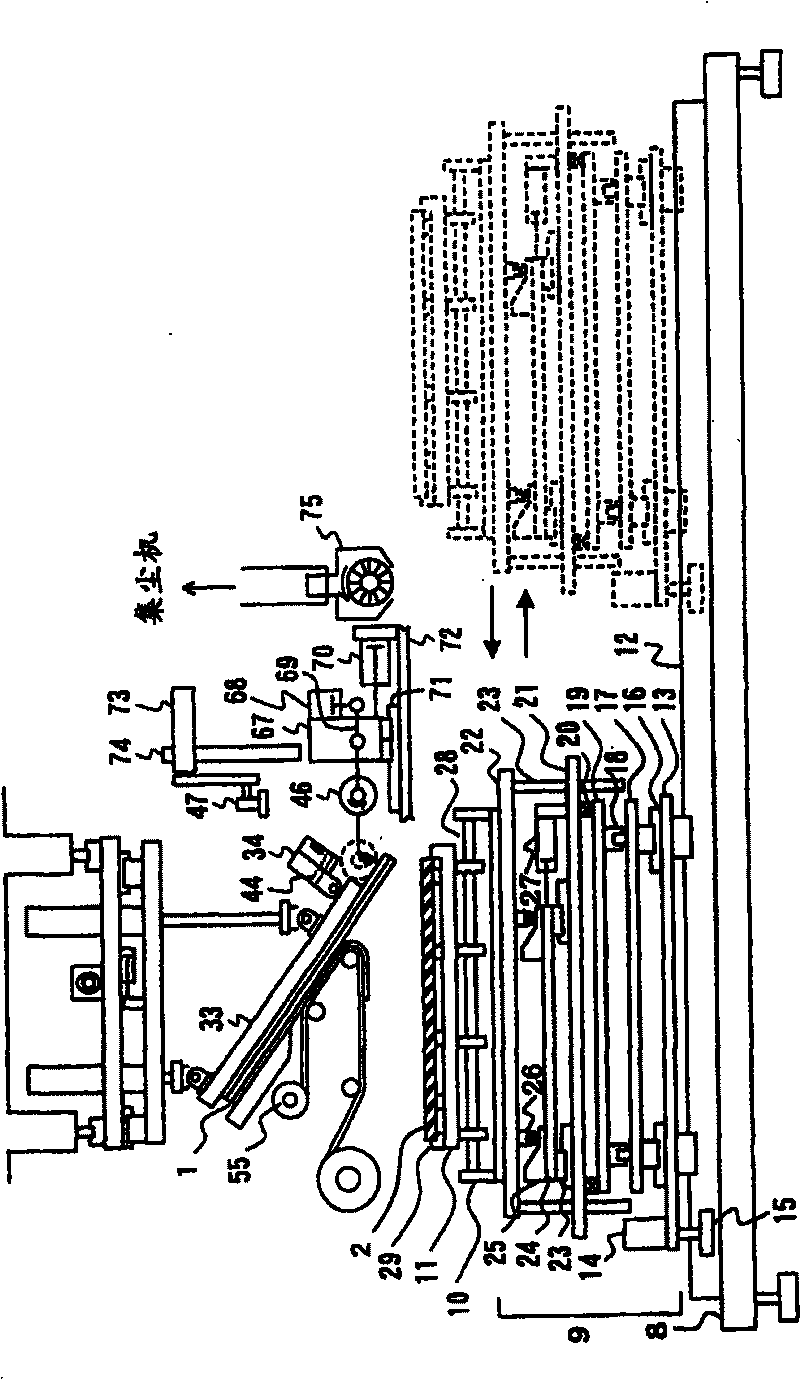

[0030] figure 1 It is a schematic diagram of main parts of the optical film sticking apparatus to which the present invention is applied.

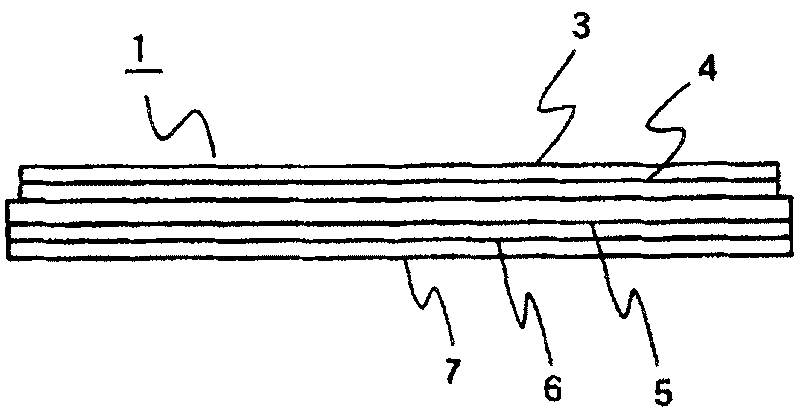

[0031] The optical film sticking device is a device for pasting the optical film (film) 1 on the image display surface of the display panel (substrate) 2, and is roughly composed of the following devices: a display panel moving mechanism (substrate holding and moving mechanism); an optical film adsorption and conveying mechanism , including an adsorption plate, a front end adsorption plate, an adsorption plate tilting mechanism, a front end adsorption plate release device and an adsorption plate release device; an adhesive material protective film peeling mechanism, including an adhesive tape and an adhesive tape moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com