Gas-added self heat-insulation composite weight-bearing build brick of concrete

A concrete and self-insulation technology, applied in climate change adaptation, building materials and other directions, can solve the problems of difficult to guarantee the quality of wall construction, high cost of wall construction, difficult to guarantee the service life of organic thermal insulation materials, etc. The effect of low comprehensive cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

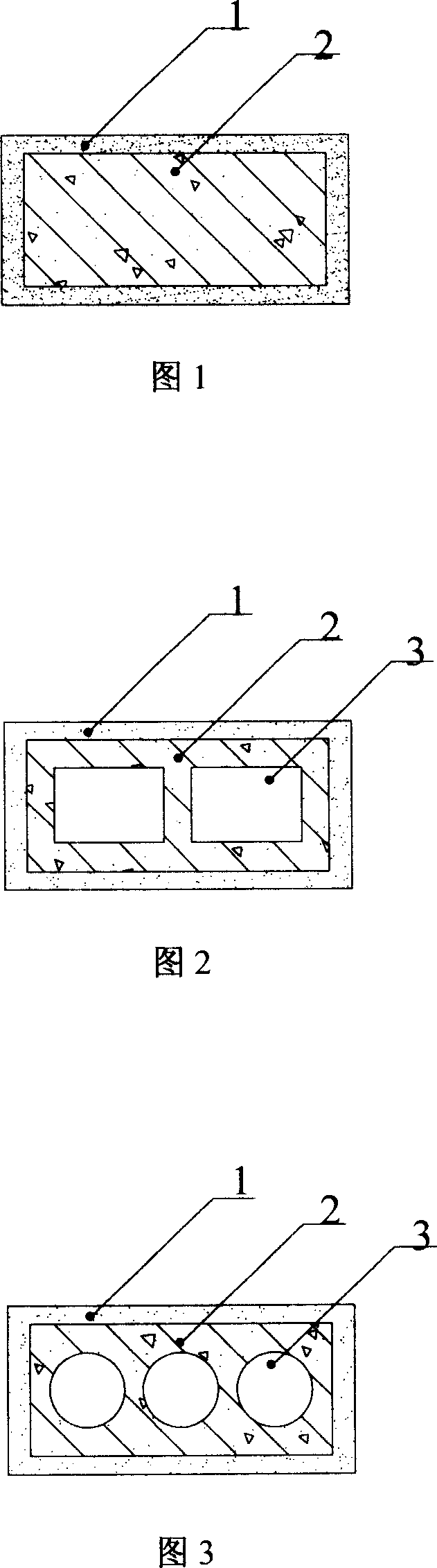

Embodiment 1

[0014] Example 1: In order to verify that the composite block has sufficient compressive bearing capacity, the test selects the compressive strength grade A3.5, the bulk density B06 quartz sand aerated block, and divides the size according to the outer dimension of the solid composite block in Figure 1 The commercial aerated concrete blocks with relatively large specifications are cut and shaped, and the aerated blocks are drilled with a low-speed electric drill, and then the holes are dug out by hand sawing according to the size of the concrete solid core block. Using crushed stone with a maximum particle size of 10mm as coarse aggregate, fine stone concrete (volume ratio: stone:sand:cement:water=1:1:1:0.75) was poured into the hole, after 40 days of natural curing, finally The surface of the test block is ground to obtain a finished self-insulating composite load-bearing block. The compression test has proved that the compressive strength of this block can reach 14MPa. This ...

Embodiment 2

[0015] Example 2: In order to produce concrete aerated self-insulating composite load-bearing blocks on a large scale in the factory, ordinary concrete block forming machines can be used to produce the concrete core inside the composite block according to the selected concrete mix ratio and core block size After 3 days of natural curing, the core blocks can be loaded into special molds and positioned. At the same time, the air-entrained concrete dry material is configured according to the ratio of 425# Portland cement 9%, quicklime 29%, sand 59%, dihydrate gypsum 2%, aluminum powder 8‰, triethanolamine 2‰, and then water and dry material 1 : 0.65 ratio to configure the air-entrained concrete slurry, stir the slurry and pour the pasty slurry into the space outside the concrete core block in the mold. Stop for about 5 hours and wait for the aerated concrete slurry to solidify, then use a wire cutter to trim the surface of the block, and then send the block with mold into the aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com