Biphenyltetracarboxylic acid dianhydride, method for producing the same, polyimide using the same and method for producing the same

A technology of biphenyltetracarboxylic dianhydride and biphenyltetracarboxylic acid, applied in the field of biphenyltetracarboxylic dianhydride and its manufacture, achieving high productivity, excellent heat resistance, and high degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

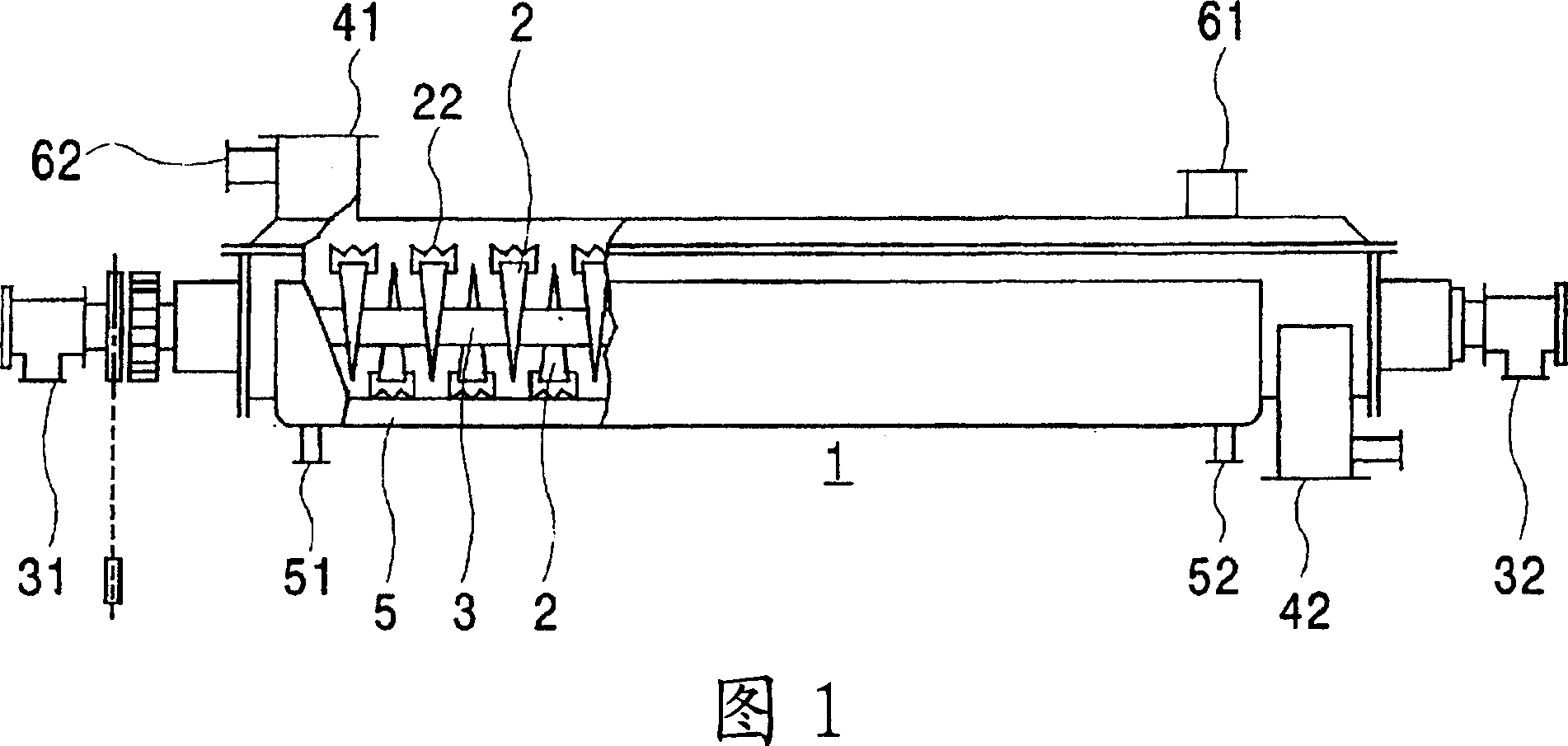

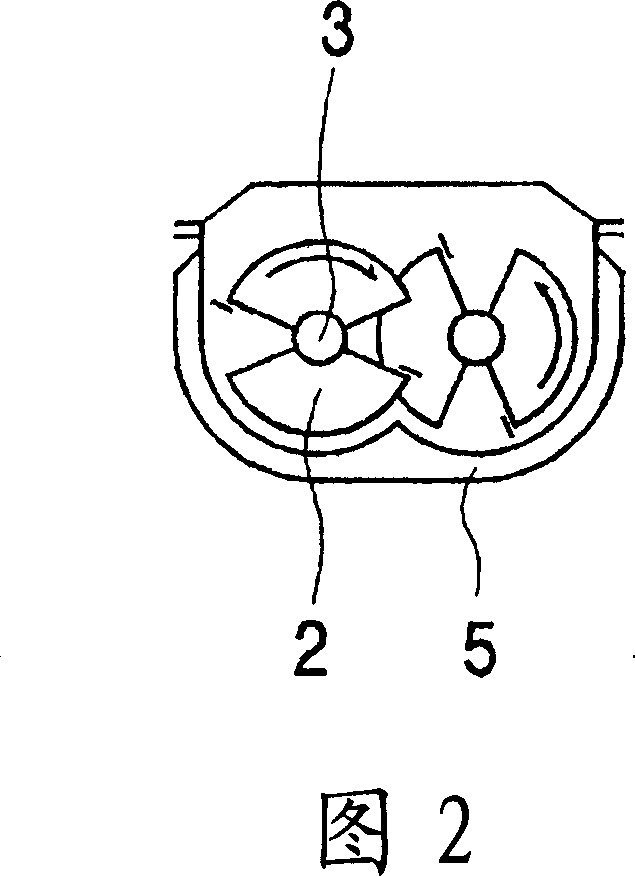

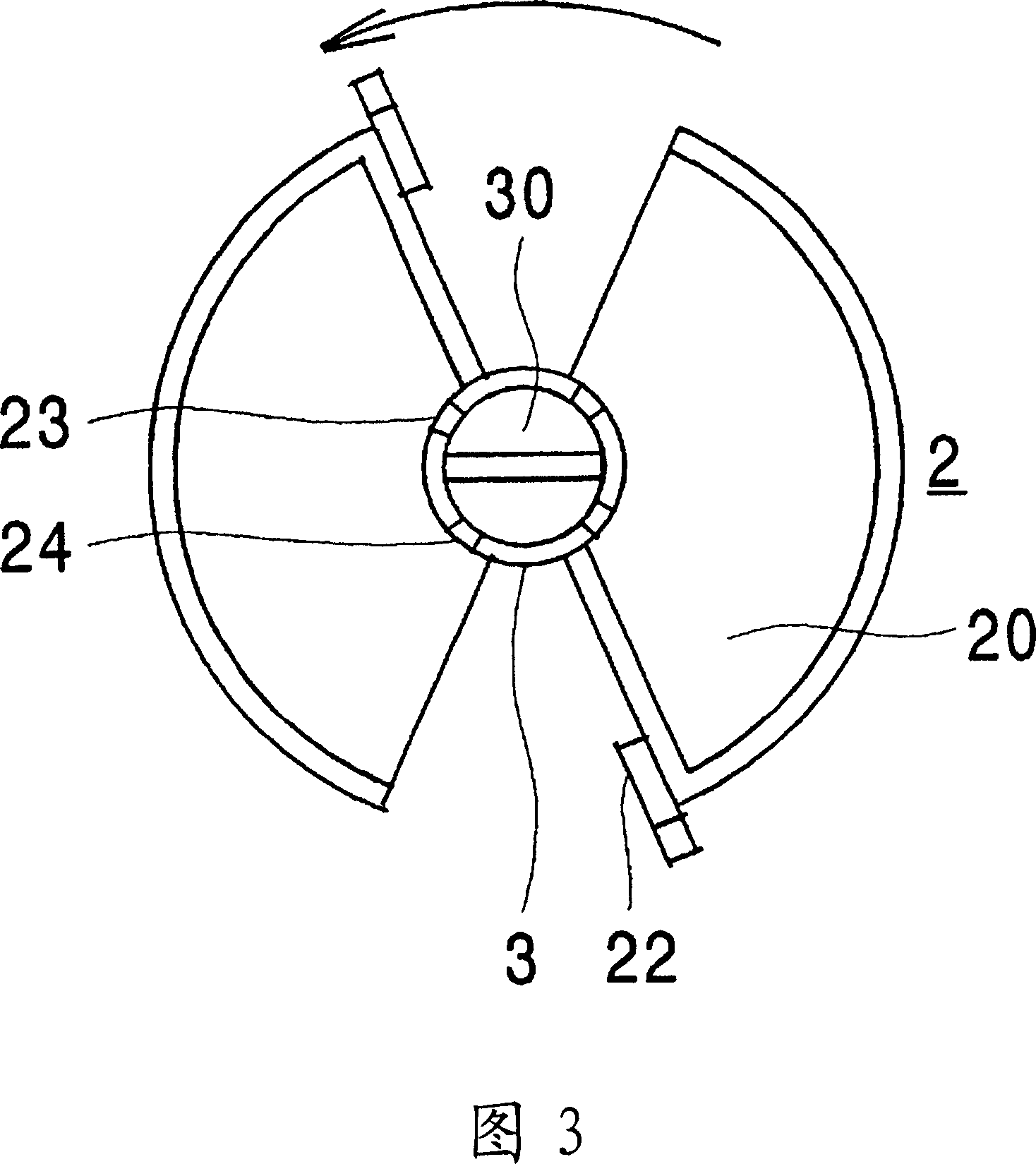

[0115] Use the heater (1) shown in Figures 1 to 4 as the heater (1) shown in Figs. A hollow rotating shaft (3) with a plurality of hollow rotating heating bodies (2) is hidden, and the heated heating medium is transported to the hollow part (20) of the rotating heating body through the hollow part (30) of the rotating shaft ), in addition also to the heating jacket (5), thereby, through the heat transfer from each surface of these rotating shafts, the rotating heating body and the heating jacket arranged as needed, the heat necessary for the reaction can be supplied. The hollow rotating heating body (2) in the heating device has a wedge-shaped shape when viewed from the side, and a roughly fan-shaped shape when viewed from the front, and is fixed to the hollow rotating shaft (3) with the shaft portion of the fan.

[0116] BTC (moisture is 18.31%) is continuously supplied to the above-mentioned heating device from the inlet (41) of the raw material at a ratio of 7.8kg / hour,...

Embodiment 2

[0121] Using the same apparatus as in Example 1, the heat treatment of BTC was performed by continuous operation. BTC (moisture is 18.31%) is continuously supplied by the raw material inlet (41) of the device with the ratio of 7.4kg / hour, and the residence time in the device is to carry out the dehydration reaction under the conditions of 7.7 hours and normal pressure, by the outlet of the product ( 42) Continuous discharge of BPDA. And, during operation, nitrogen gas was introduced from the inlet (61) at a rate of 70 L / min and discharged from the outlet (62). In addition, by adjusting the temperature and flow rate of the heating medium, the heat necessary for the reaction is supplied to achieve the prescribed operating conditions. The heat treatment conditions of the raw materials are shown in Table 2.

[0122] temperature(°C)

time (hours)

Heating rate (℃ / hour)

20→110

0.5

180

110→176

0.5

132

176→210

...

Embodiment 3

[0130] Using the same apparatus as in Example 1, the heat treatment of BTC was performed by batch operation.

[0131] 35kg of BTC (moisture content: 18.31%) was added to the device in advance from the raw material inlet (41). The heat treatment conditions of the raw materials are shown in Table 3.

[0132] In addition, the temperature rise of the BTC is carried out by increasing the temperature of the heating medium supplied to the sleeve (5), but the movement of the BTC is not carried out during the temperature rise (in the following examples / comparative examples, unless otherwise specified, is the same as this).

[0133] temperature(°C)

Example 3

Example 4

Example 5

time (hours)

Heating rate

(℃ / hour)

time (hours)

Heating rate

(℃ / hour)

time (hours)

Heating rate

(℃ / hour)

60→100

0.5

80

2.0

20

0.5

80

100→180

0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com