FBG strain transducer strain-wavelength calibrator under low-temperature liquid helium environment

A technology of strain sensor and wavelength calibration, applied in the direction of measuring device, using optical device, using optical device to transmit sensing components, etc., can solve the problems that cannot meet the requirements of FBG strain high-precision calibration experiment, and achieve simple structure and high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

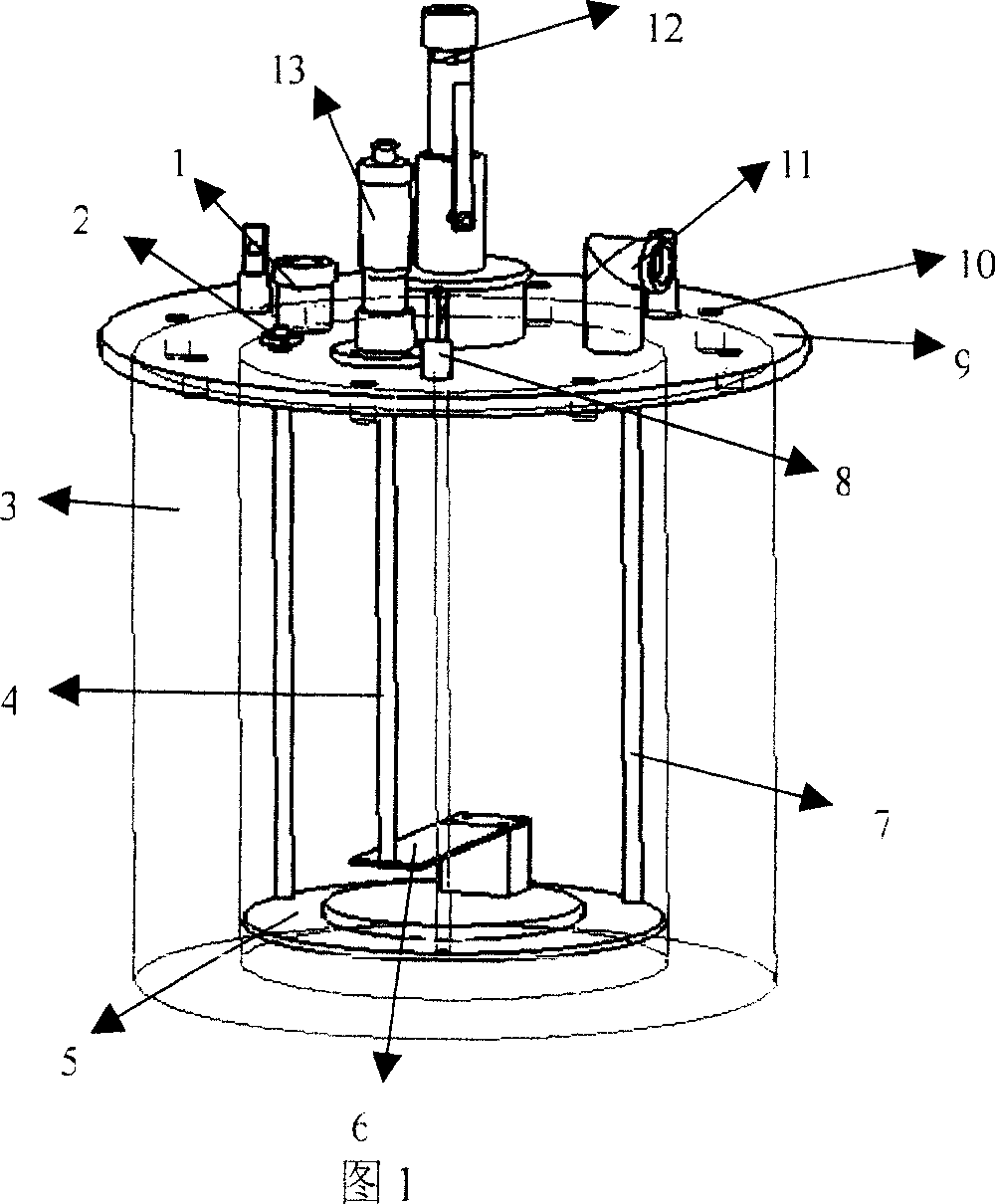

[0023] As shown in Fig. 1, the cantilever beam 6 is fixed on the cantilever beam support platform 5, and the support platform 5 is connected to the Dewar cover 9 through a fixed tie rod 7, so that the entire device can be easily extracted.

[0024] The grating sensing part of the FBG strain sensor to be calibrated is pasted on the cantilever beam 6, and the optical fiber interface of the FBG strain sensor is connected to the inner port of the optical fiber adapter 2. The outer port of the fiber optic adapter 2 is connected to an output fiber for transmitting the light source signal and the sensing signal to the FBG demodulator. Before starting the calibration, after the entire experimental device is installed, the cryogenic solution-liquid helium is poured into the Dewar 3 through the cryogenic liquid infusion device 12 until the liquid helium covers the entire cantilever 6. After the temperature stabilizes, it can be considered that the temperature in Dewar 3 is the liquid helium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com