Method for cleaning electrolyte in the bottom of residual electrolysis anode

A cleaning method and technology of aluminum electrolytic anodes, which are applied in the field of residual electrolyte cleaning, can solve problems affecting the cleanliness of residual electrodes, no records, and affecting the oxidation resistance of carbon anodes, so as to avoid equipment idling, improve cleanliness, and improve The effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

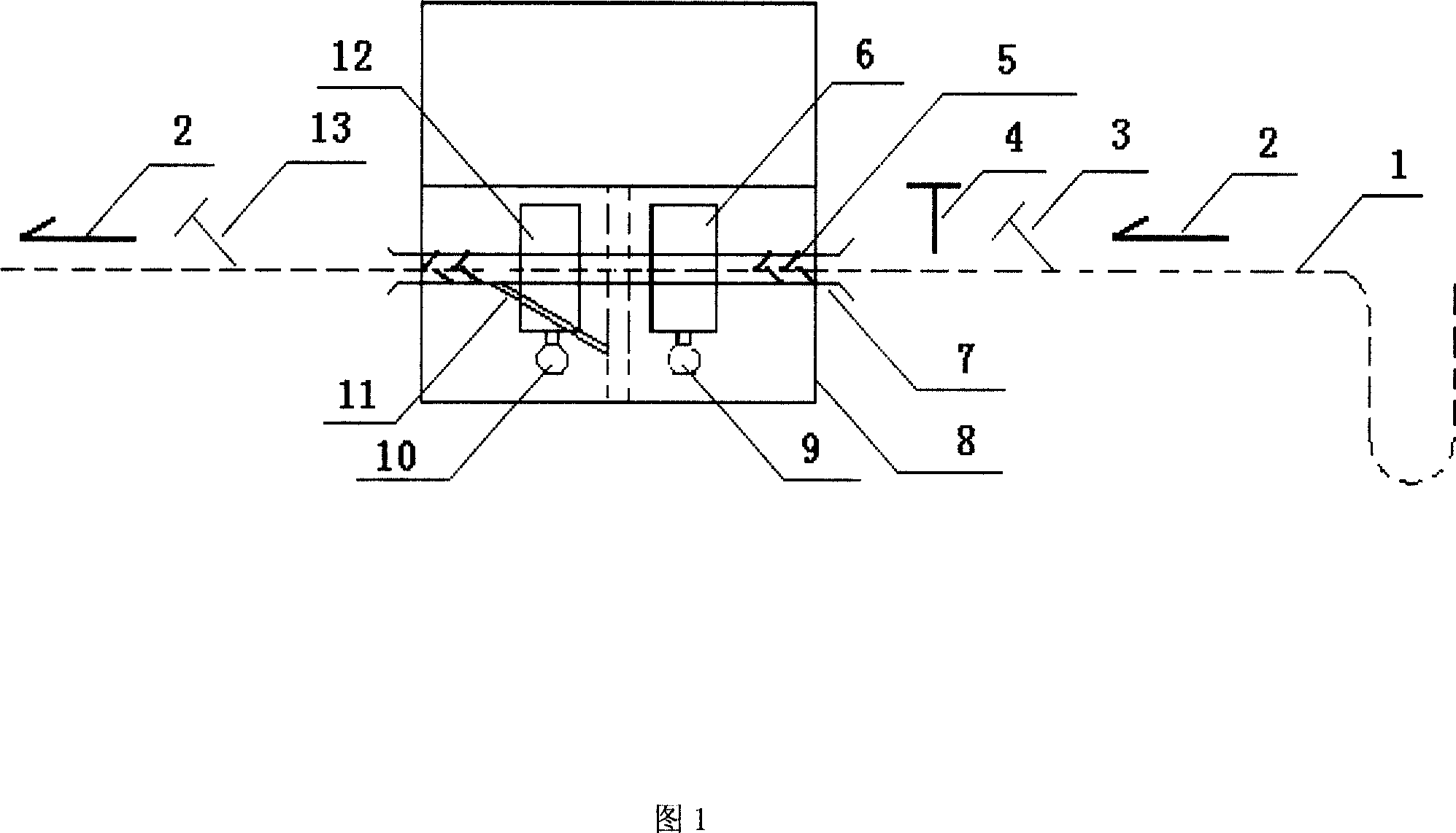

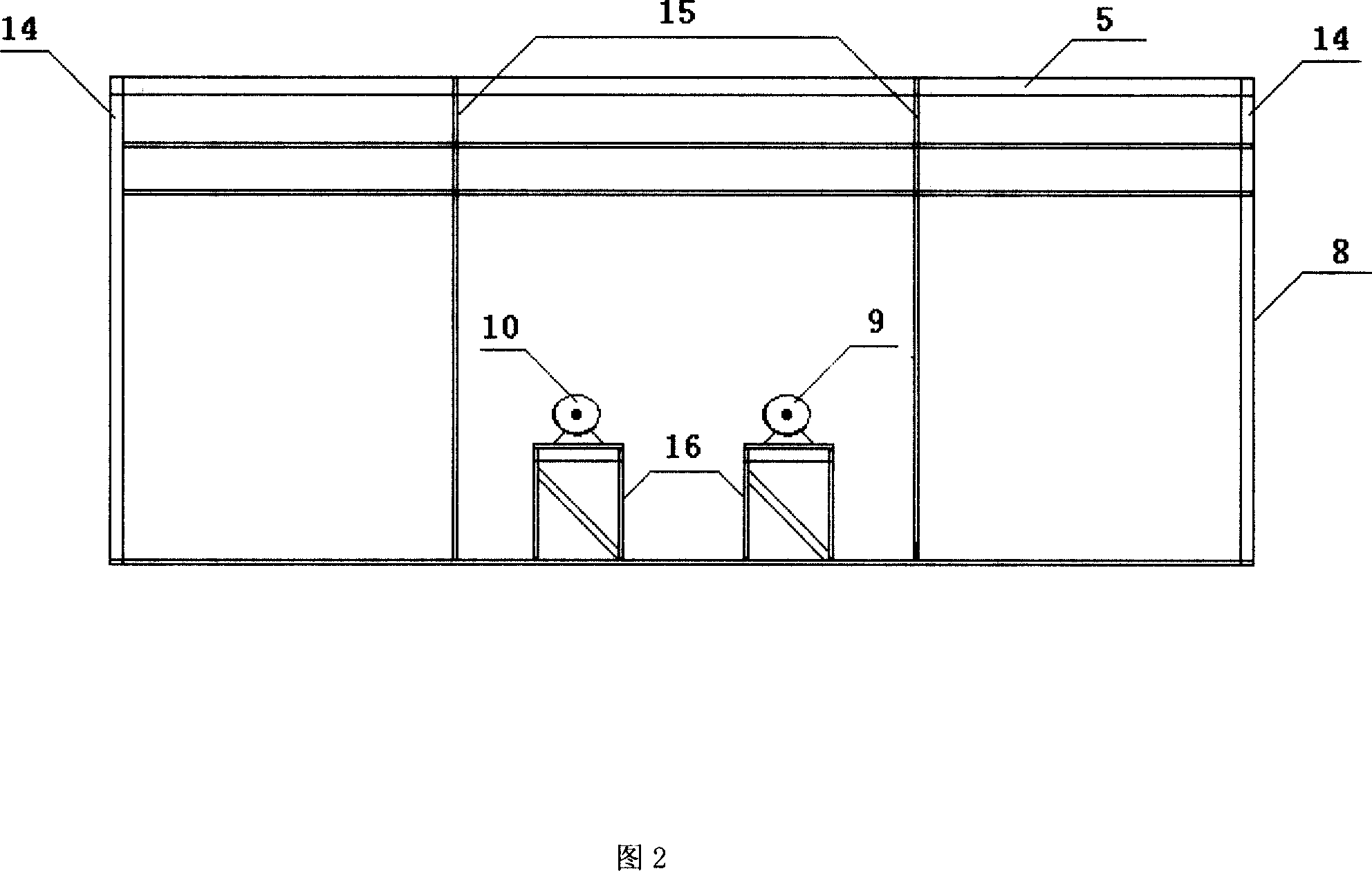

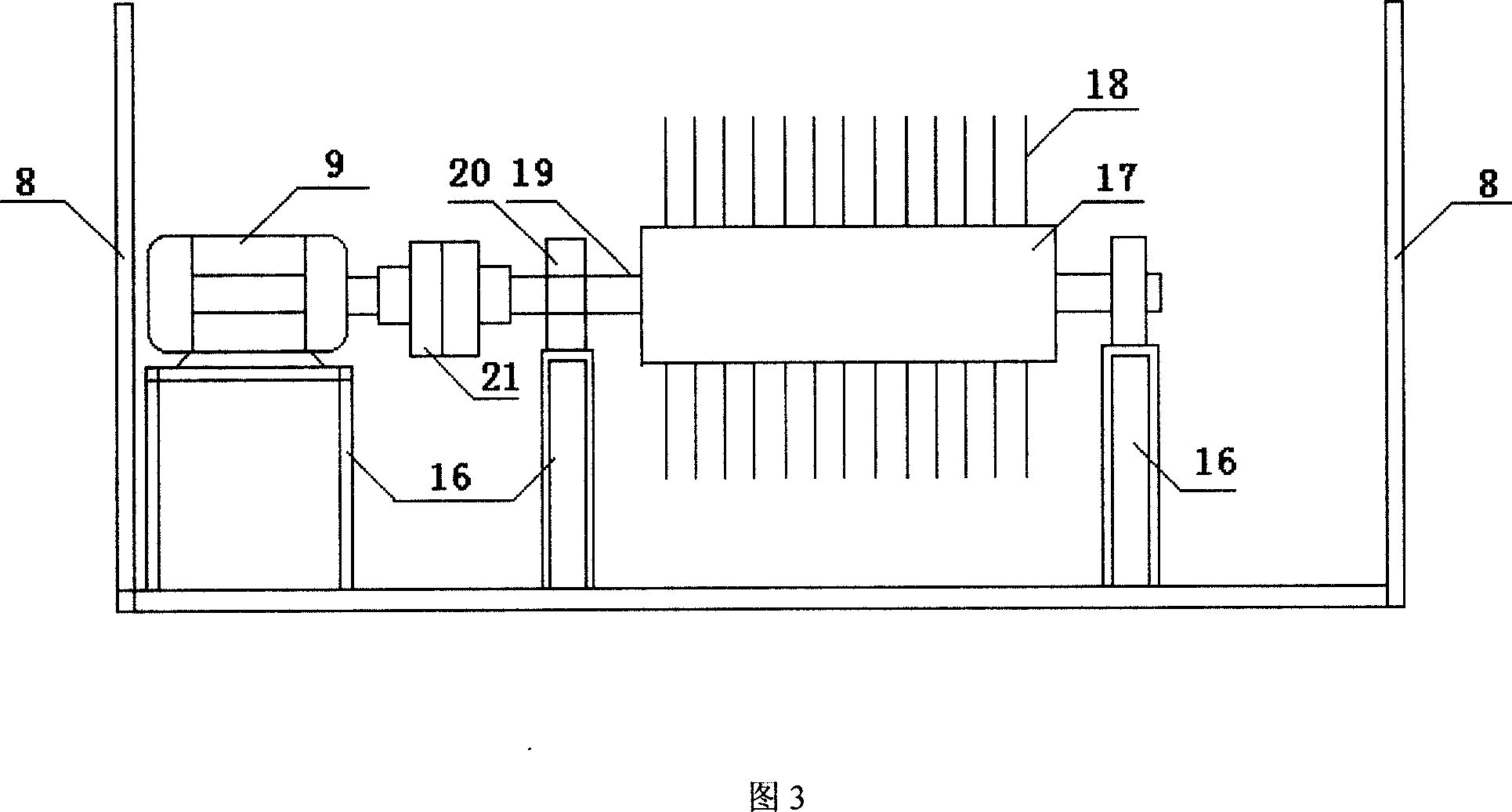

[0015] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the method for cleaning the bottom of the aluminum electrolytic anode residues of the present invention includes a catenary trolley 2 for transporting the residues, a 1# electrolyte cleaner 6, a front proximity switch 3, and a trolley stopper 4. 2# electrolyte cleaner 12, rear proximity switch 13, cleaner PLC controller 27, 1# cleaner converter 23 and 2# cleaner converter 29. The cleaning method includes an induction step, a signal transmission step, a confirmation step, an instruction step, a cleaning step, and a removal step; The switch 3 and the rear proximity switch 13 detect whether the catenary trolley 2 suspended on the catenary transportation line is in place; the signal transmission step is to transmit the signal sensed by the front proximity switch 3 and the rear proximity switch 13 To the process of the cleaner PLC controller 27; the confirmation step is to confirm whether the cleaning area has the process of cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com