Main bearing cover for IC engine

A technology for main bearing caps and internal combustion engines, applied to crankshaft bearings, etc., can solve problems such as insufficient main bearing cap rigidity, main bearing hole coaxiality and cylindricity, increased engine manufacturing costs, and many machining surfaces, etc., to achieve reduction The effect of machining surface, reducing manufacturing cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

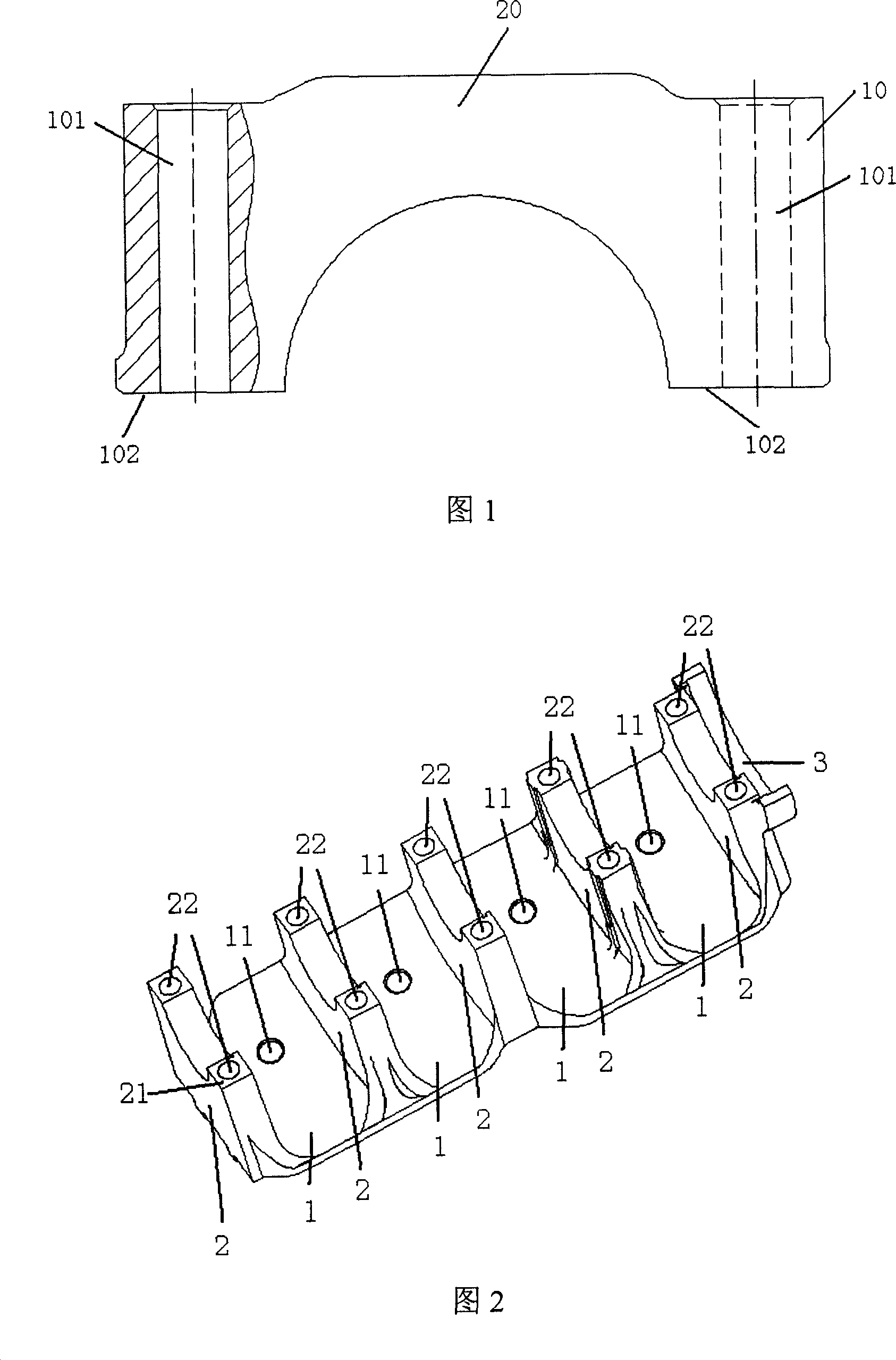

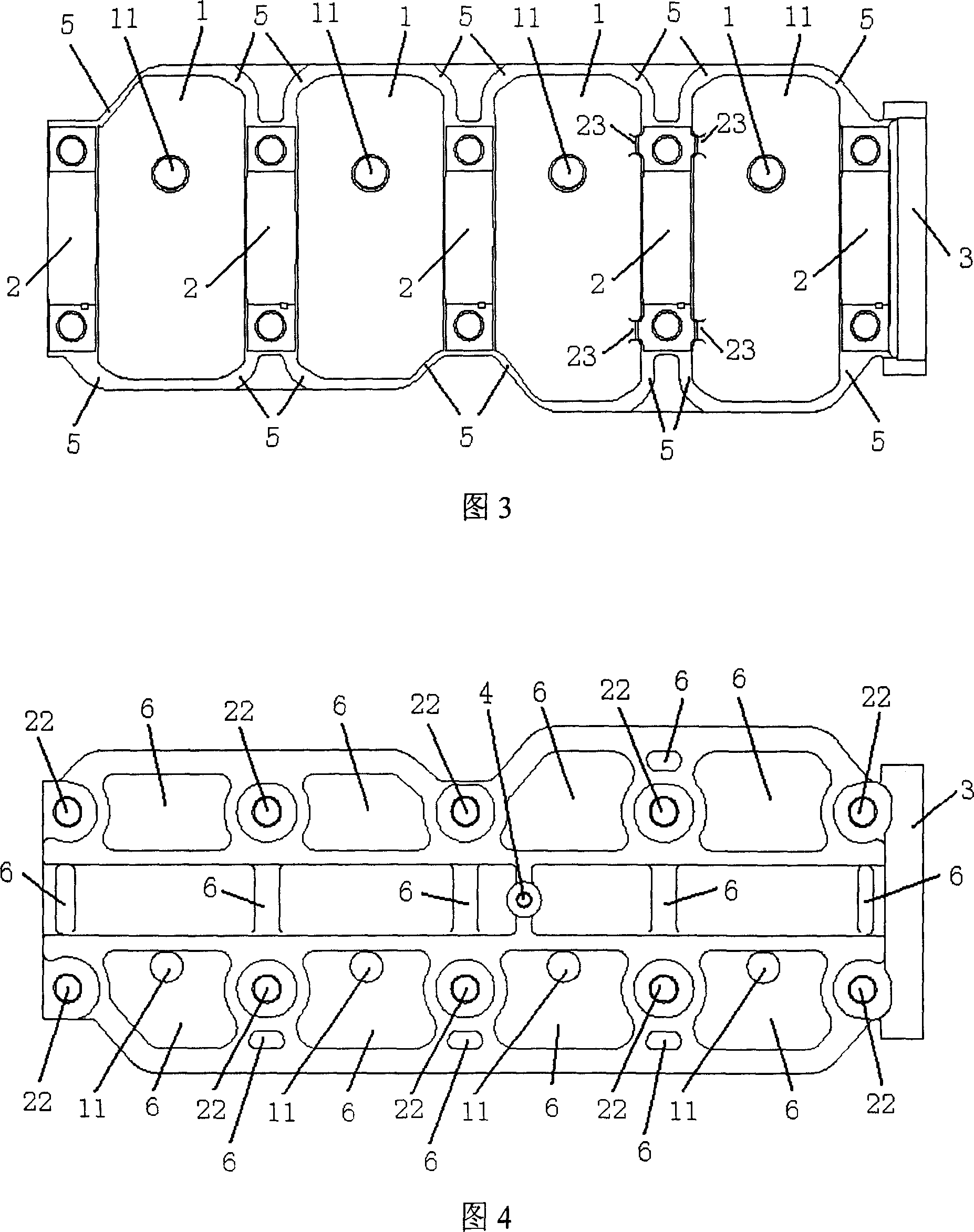

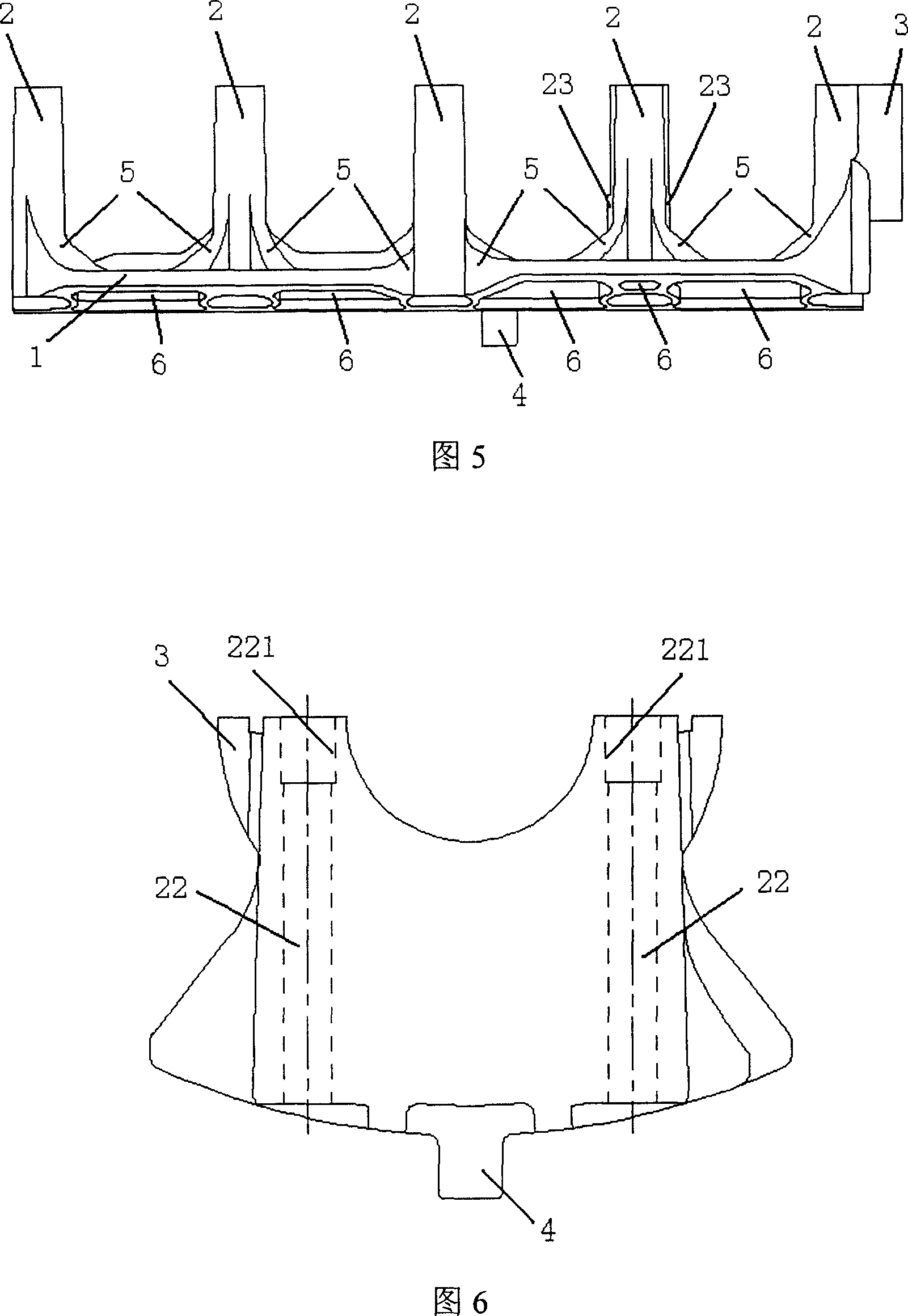

[0029] As shown in Figure 2-7, a main bearing cap of an internal combustion engine has a tooth-shaped structure, and four arc-shaped connecting walls 1 connect five bearing caps 2 together so that the bearing caps 2 are connected to each other. It is formed as a whole, and the arc-shaped connecting wall 1 is integrally formed with each of the bearing caps 2 .

[0030] The joints between the arc-shaped connecting wall 1 and the bearing cover part 2 are all reinforced with reinforcing ribs 5, so that the rigidity thereof is greatly improved.

[0031] Due to the use of the arc-shaped connecting portion, during the working process of the engine, the oil flowing down from the crankshaft will accumulate on this arc-shaped connecting wall 1, and cannot return to the oil pan in time, so that in each arc An oil drain hole 11 is made on the connecting wall to ensure that the machine oil can flow back into the oil pan quickly.

[0032] On the rear end of the main bearing cap, a semicirc...

Embodiment 2

[0040] The difference between this embodiment (not shown in the figure) and embodiment 1 is that there is only one above-mentioned arc-shaped connecting wall 1 , which connects the two bearing caps 2 together to form a whole. The structure of the rest of this embodiment can refer to Embodiment 1.

[0041] The main bearing cap described in this embodiment can be used in a single-cylinder engine.

[0042] In the above-mentioned embodiments, the connecting part can adopt any structural form according to actual needs, not limited to the arc-shaped connecting wall, the bolt through holes can also be processed by drilling, and other parts can also be changed according to needs.

[0043] It is obvious to those skilled in the art that the main bearing cap disclosed in the present invention can be used for in-line, V-type and opposed engines with any number of cylinders. Due to space limitations, the foregoing implementation manners are not described here one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com