Double-work position automatic die-changing system for hydraulic press

A technology of automatic mold change and hydraulic press, applied in the direction of presses, manufacturing tools, etc., can solve the problems of complex structure of mobile worktable, long time for mold change, low work efficiency, etc., and achieve fast and stable replacement, fast and stable transportation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

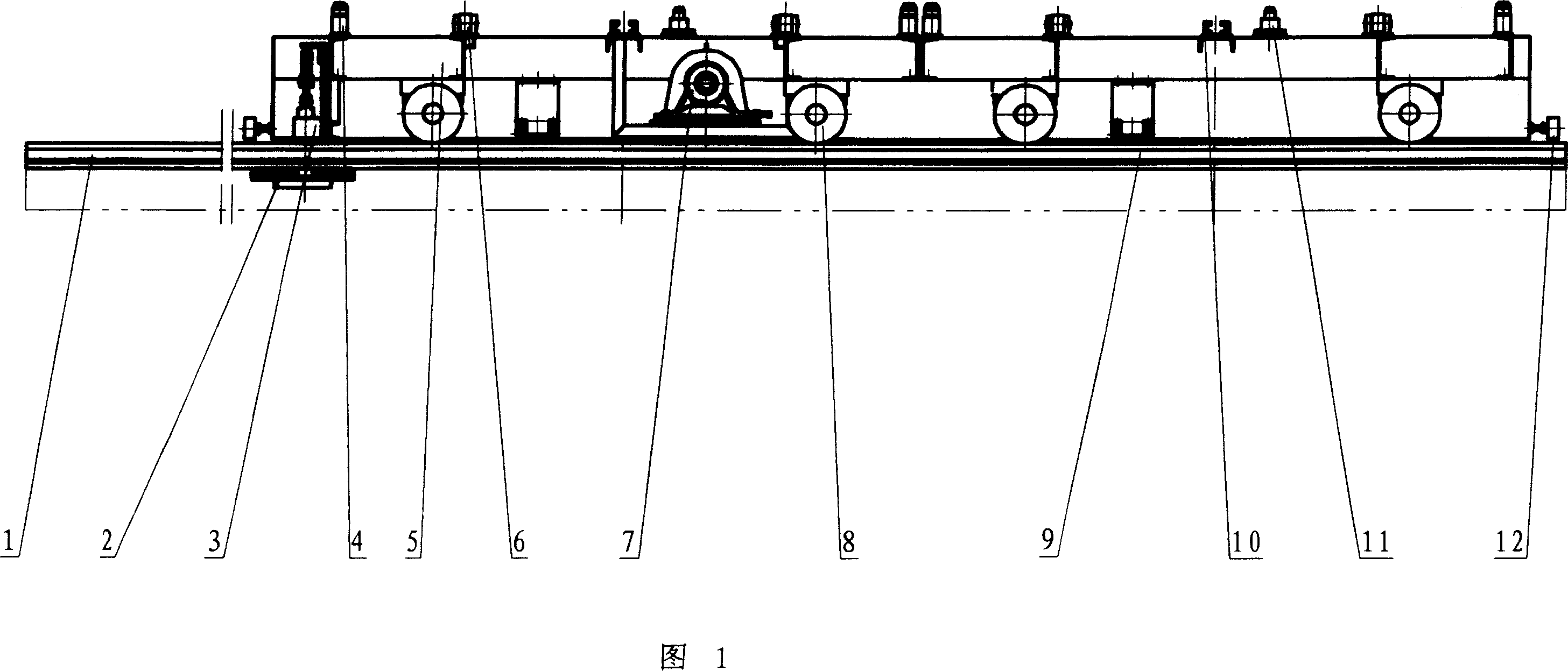

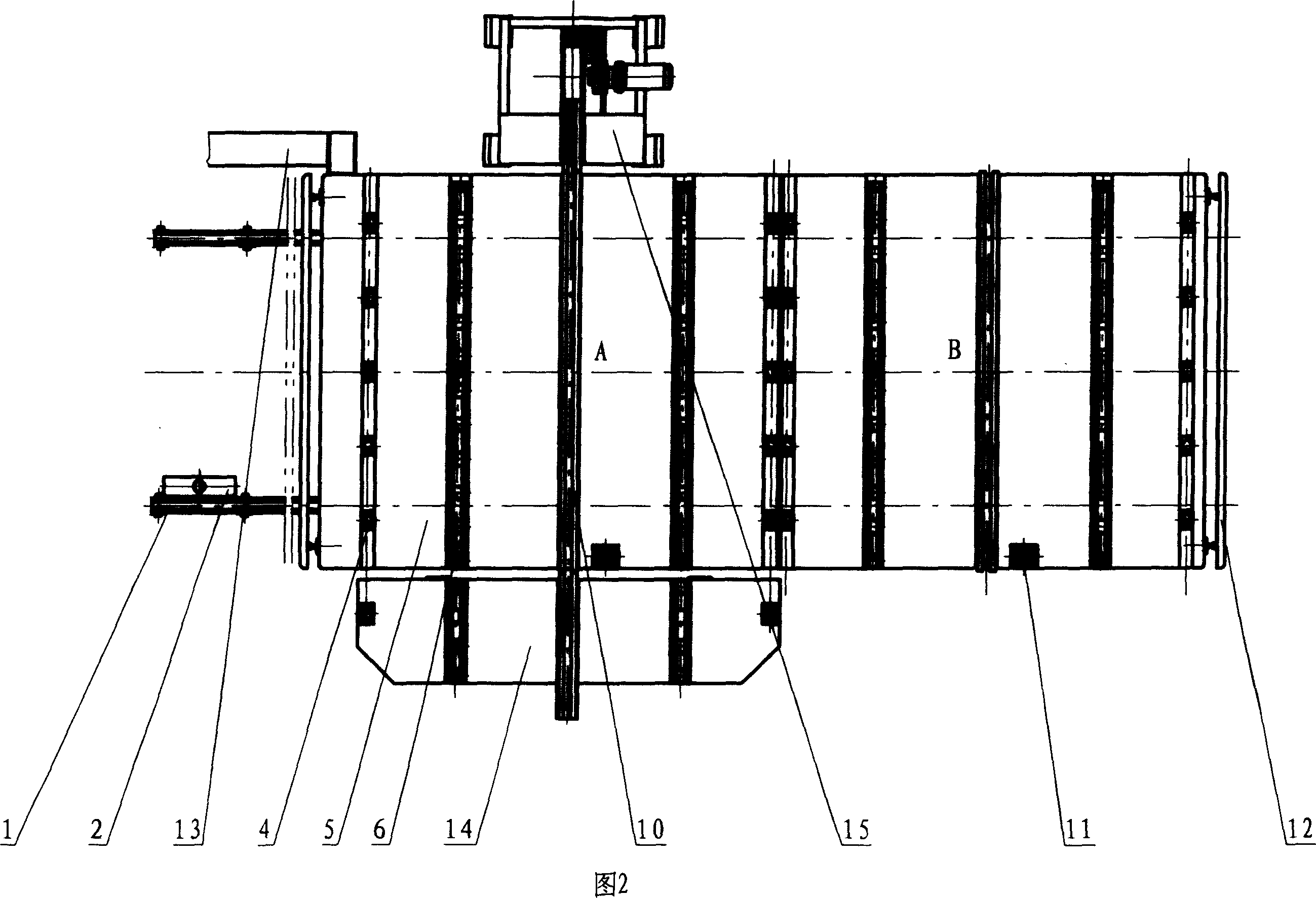

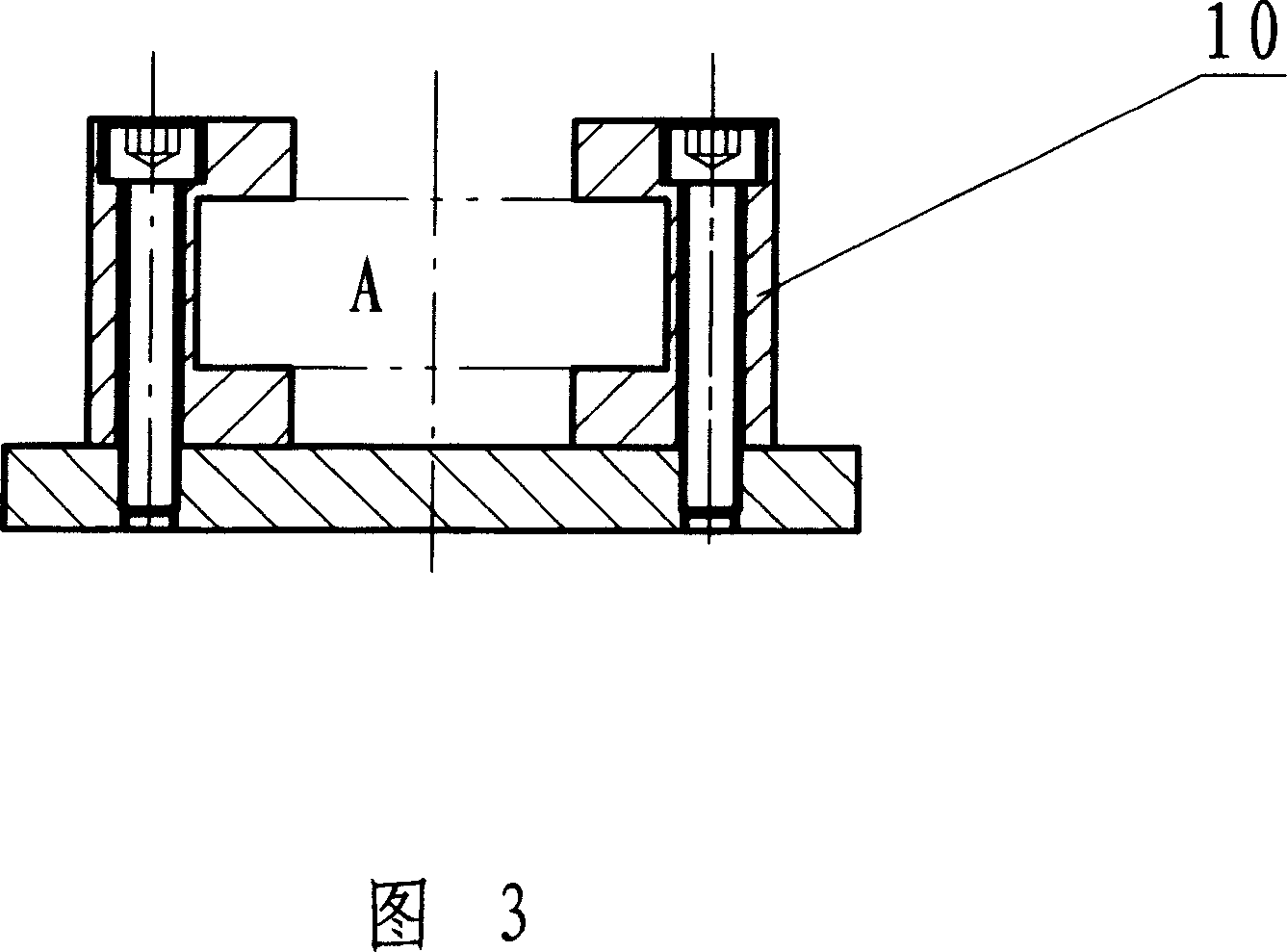

[0026]Please refer to Fig. 1 and Fig. 2, the double-station automatic die change system of the hydraulic press, a track 1 is laid horizontally beside the hydraulic press, and a changer consisting of a die bearing platen 5, a traveling wheel 8 and a traveling drive device 7 is placed on the track. For the mold trolley, the walking drive device adopts sprocket chain transmission. The platen of the mold changing trolley is equipped with two mold bearing stations A and B along its traveling direction. The chain running groove 10 of walking direction, its structure is shown in Fig. 3, and it is made of two steel bars with square grooves arranged oppositely, and the both sides of chain running groove are respectively fixed with an upper side paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com