PCB hollow coil current-sensing device

A current sensor and air-core coil technology, applied in the direction of inductors, voltage/current isolation, circuits, etc., can solve the problems of low anti-interference ability and low precision, and achieve the effect of facilitating mass production, ensuring measurement accuracy, and fine manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

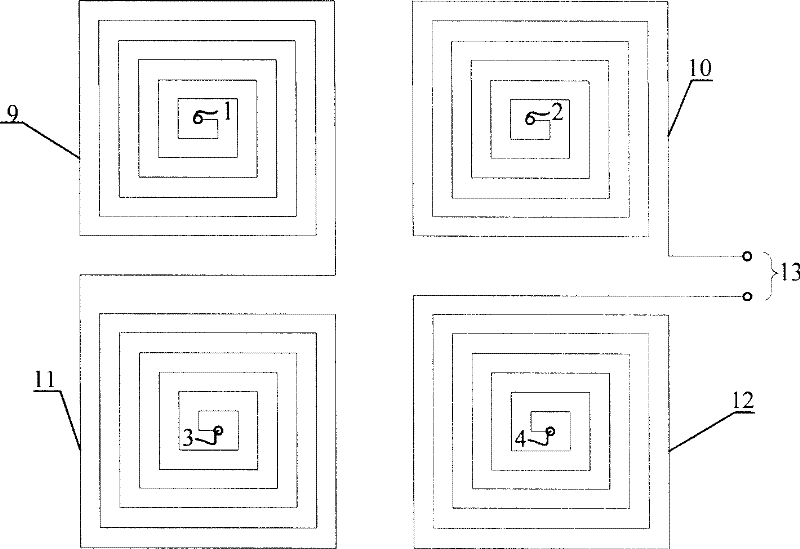

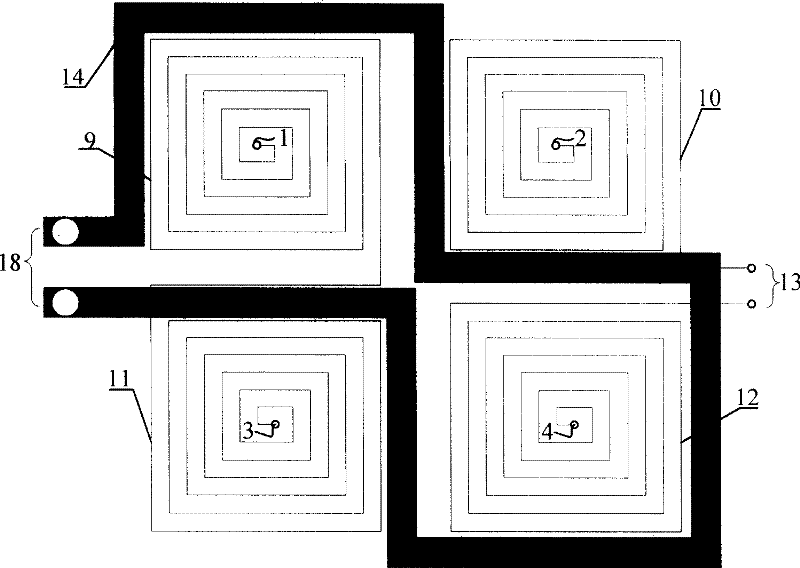

[0021] see figure 1 , figure 1 It is the wiring diagram on the top layer of the PCB current sensor. 9, 10, 11, and 12 are the spiral coils formed by the printed lines on the PCB, and they are evenly distributed around a center; 1, 2, 3, and 4 are the coils on the PCB. The via holes are connected to the upper and lower spiral coils, and 13 is the output end of the sensing coil (the secondary output end of the PCB type air-core coil current sensor). When the interfering alternating magnetic field at the far end passes through the sensing coil of this layer, the induced electromotive forces generated by the two helical coils 9 and 11 are equal in size and opposite in direction, and they are connected in series to cancel each other out, and the induced electromotive forces generated by 10 and 12 will also Also cancel each other out.

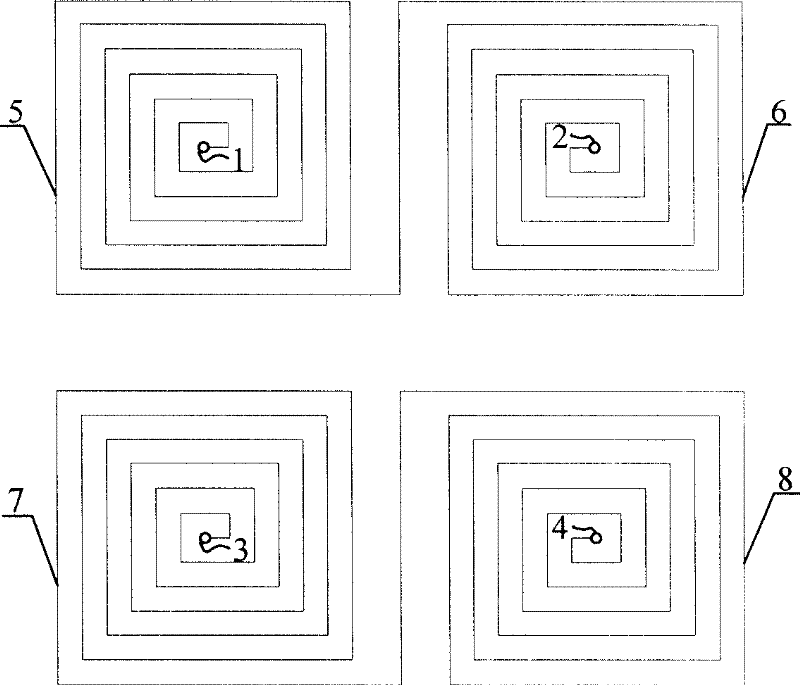

[0022] figure 2 It shows the above-mentioned winding diagram on the bottom layer of the PCB current sensor. Similarly, 5, 6, 7, and 8 are all sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com