Discharge and exhaust pipe joint

An exhaust pipe and interface technology, applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, pipes, etc., can solve the problems of troublesome processing, loss of sealing effect, small passage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

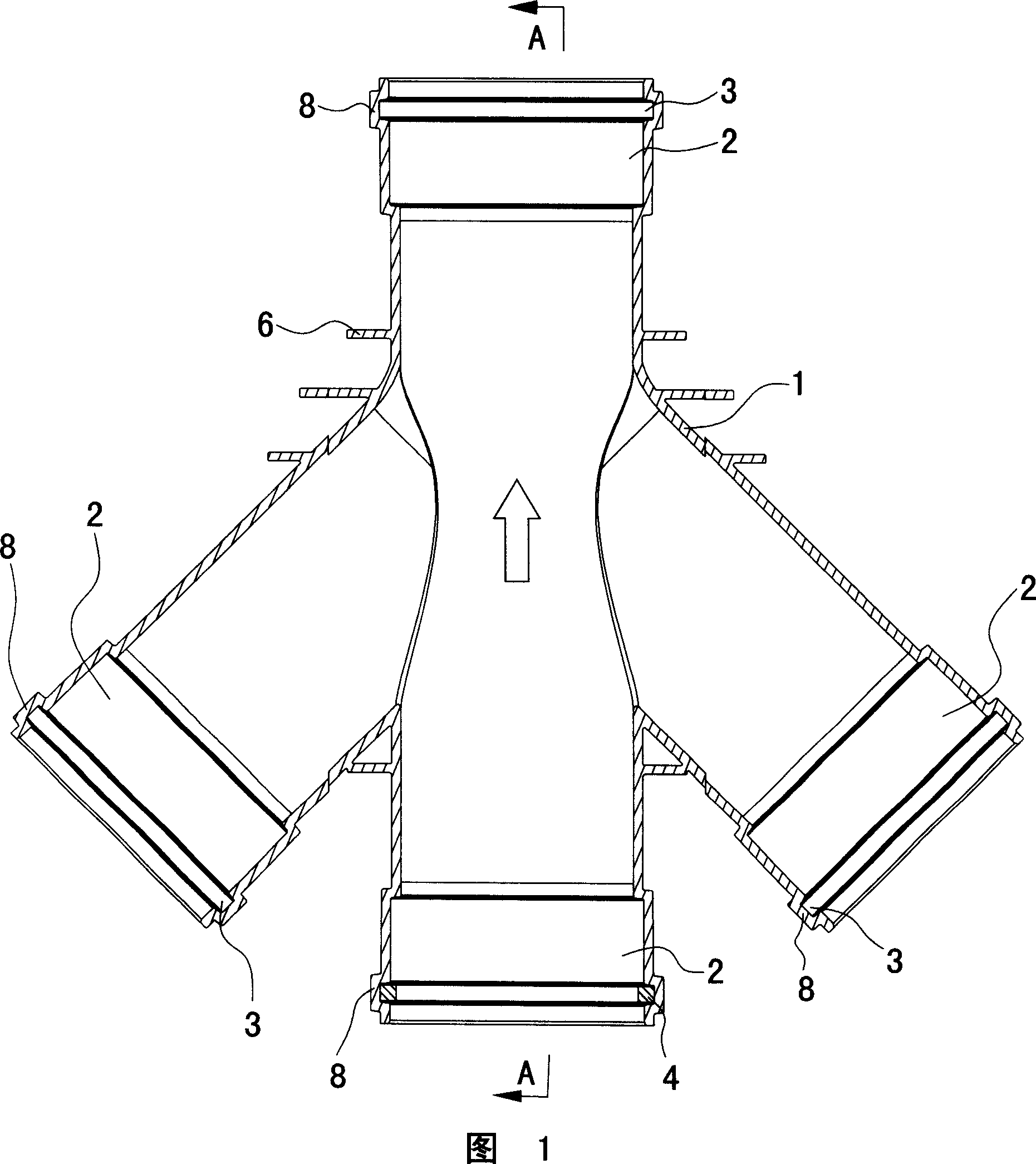

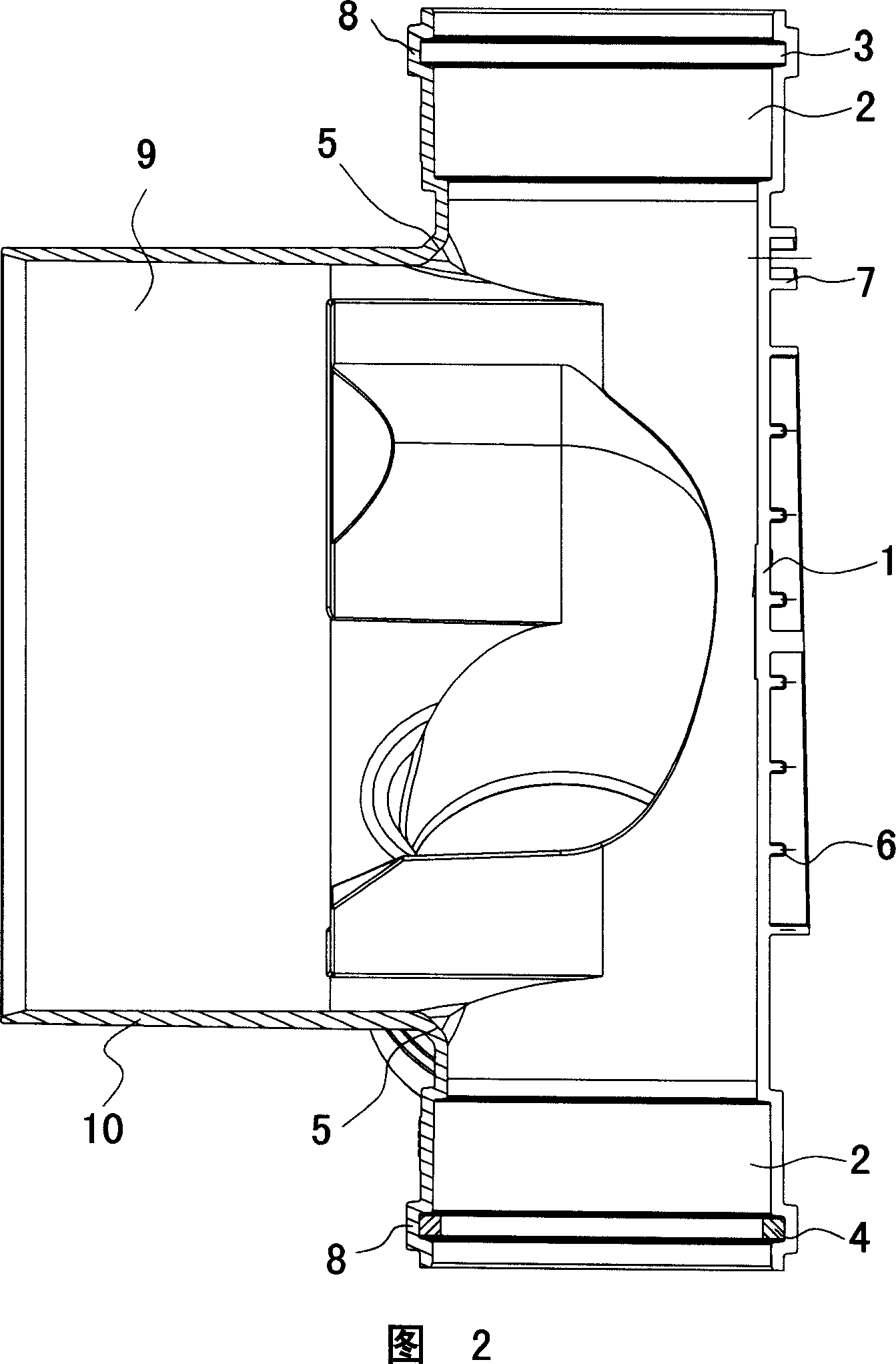

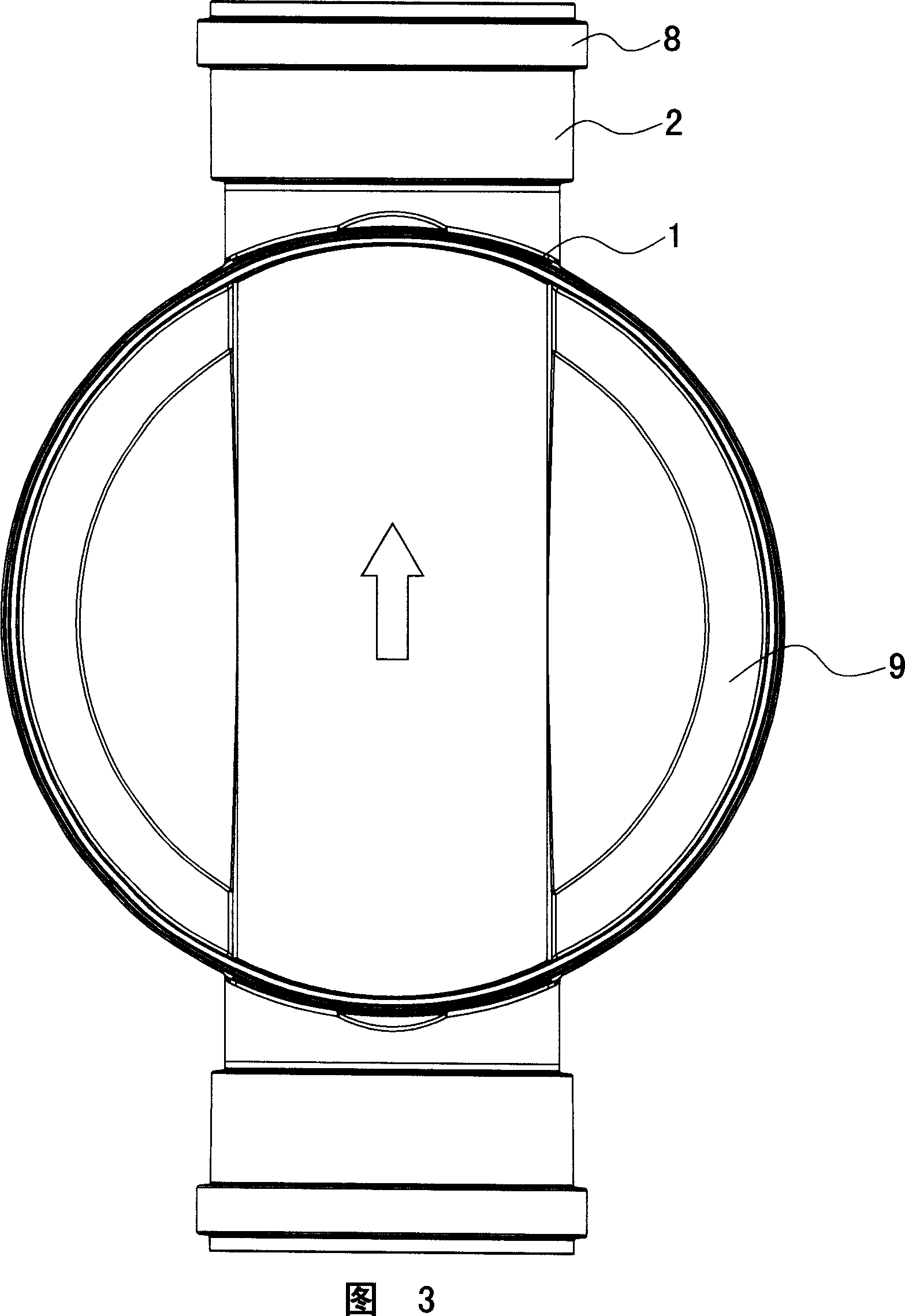

[0010] The invention discloses a sewage discharge and exhaust pipe joint. As shown in FIG. 1, a joint body 1 made of plastic is connected with an interface 2, and the interface can be multiple, such as two, three, four, etc. Its main technical feature is that the inner wall of the interface 2 is formed with a sealing groove 3, and a sealing ring 4 is installed in the sealing groove 3, and the sealing ring is in contact with the outer wall of the pipe, so as to overcome the shortcomings of the prior art glued and bonded and easy to separate , the sealing ring seal is also called flexible seal, such as rubber sealing ring, etc., the sealing performance is very reliable, when the pipe displacement changes, such as thermal expansion and cold contraction elongation or shortening, and deviation from the installation center line, it can be completely obtained by itself adjust. There is a flaring 8 on the interface, and the sealing groove is made in the flaring. The flaring is also ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com