Linear compressor

A linear compressor, suction valve technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of reducing the diameter of the piston 20, increasing the fluid resistance, and difficult to fix the suction valve 22, etc. Smaller effects of reducing dead volume, reducing fluid resistance, deformation or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be explained below with reference to the accompanying drawings.

[0055] FIG. 4 is a sectional view showing a linear compressor according to a first embodiment of the present invention. FIG. 5 is an exploded perspective view showing a suction valve and a piston included in the linear compressor according to the first embodiment of the present invention. 6 to 9 are views sequentially showing an initial retreat state, a fully retracted state, an initial forward state, and a fully advanced state of the piston of the linear compressor according to the first embodiment of the present invention.

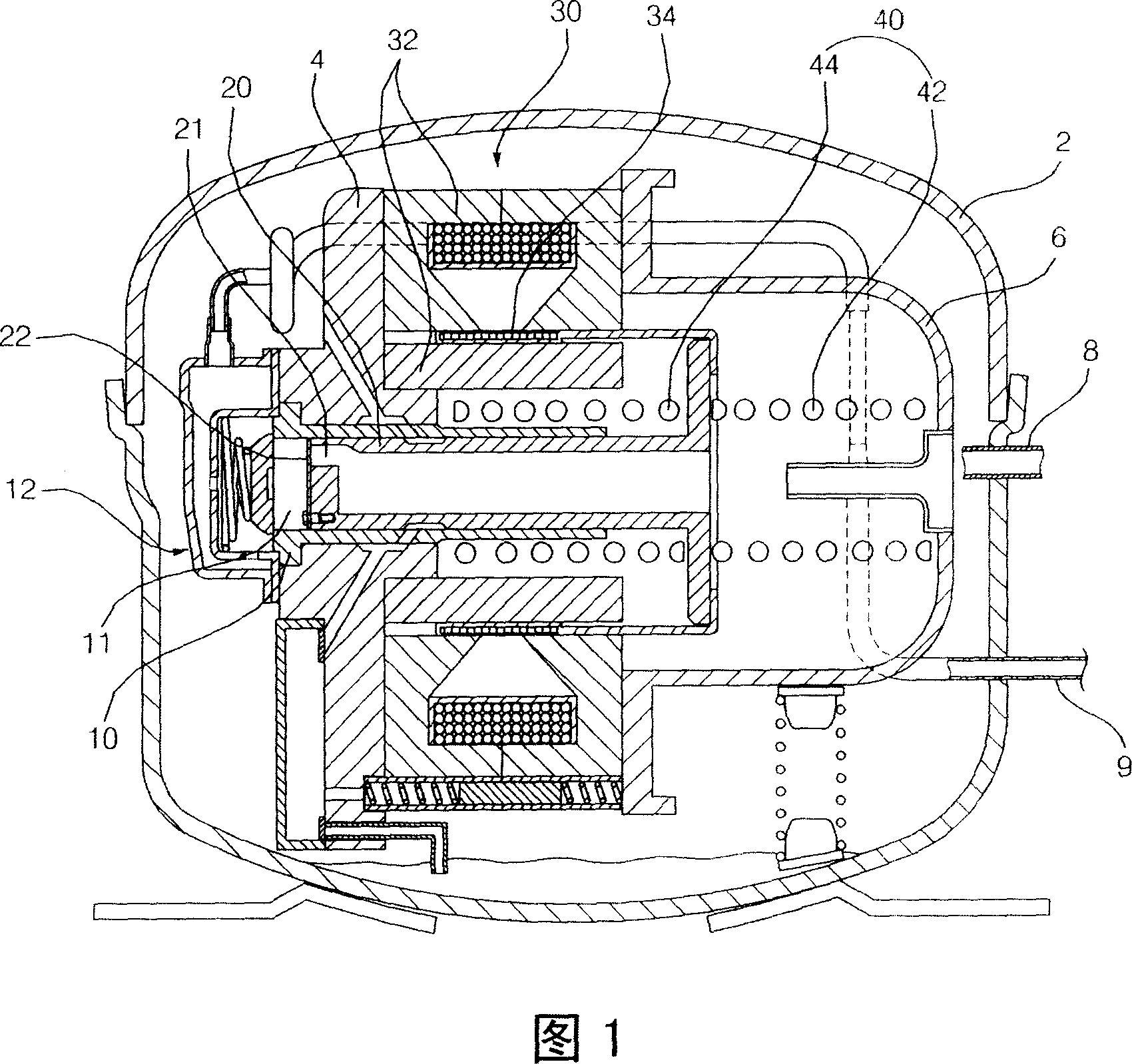

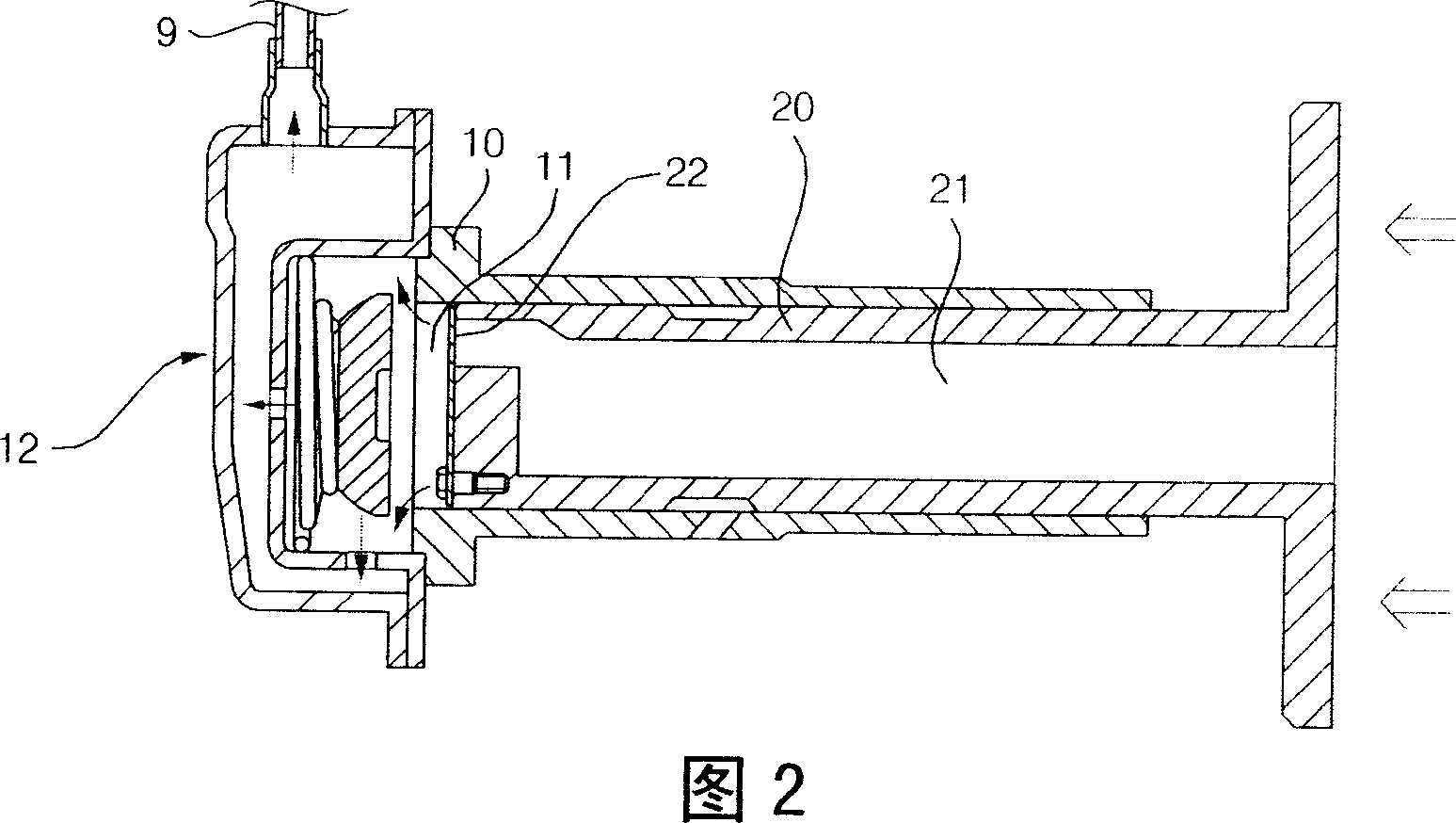

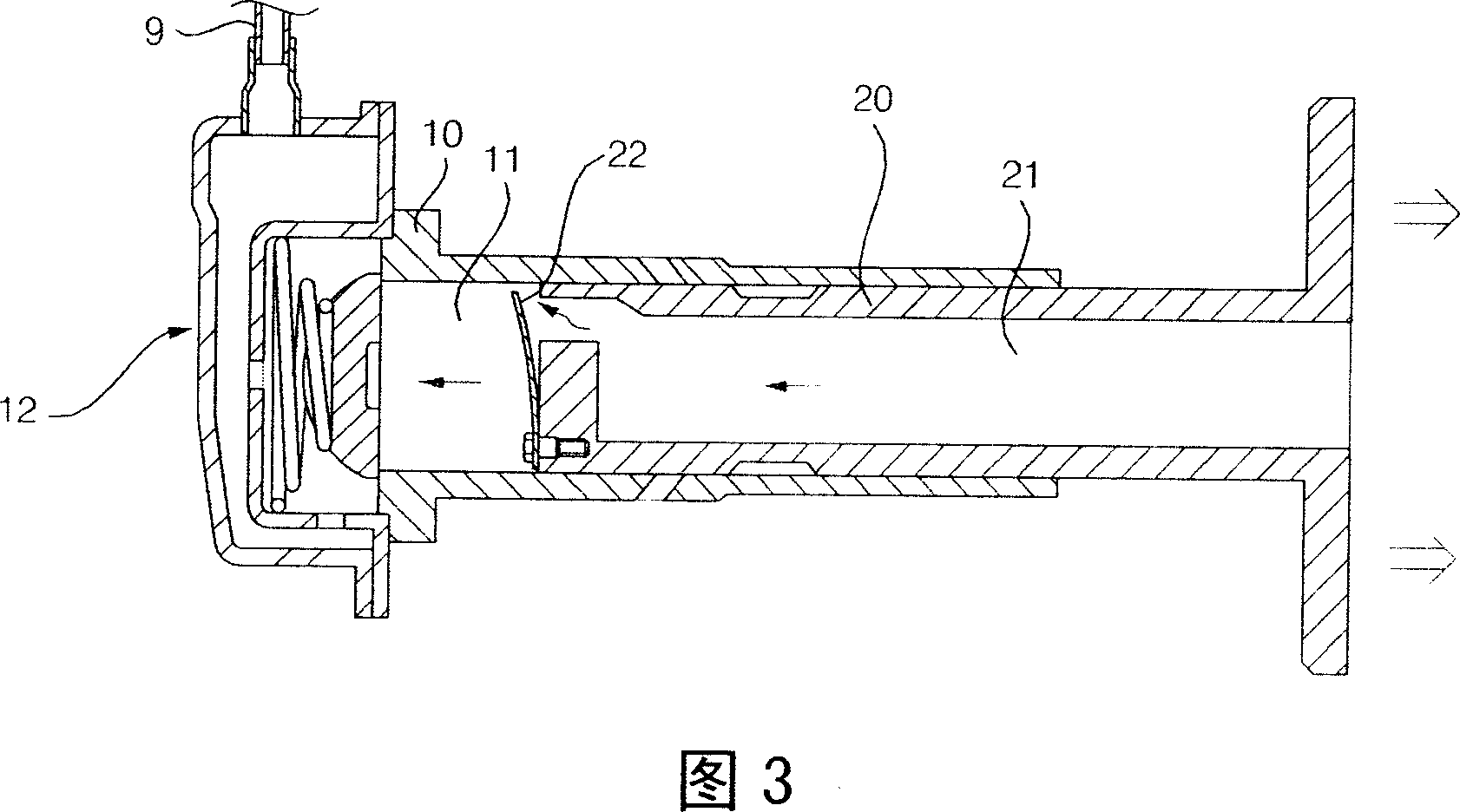

[0056] As shown in FIGS. 4 to 9 , the linear compressor according to the first embodiment of the present invention includes: a housing 50 configured to allow the introduction and discharge of working fluid; a cylinder block 60 and a rear cover 62 disposed in the housing 50 ; And a compression unit P disposed between the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com