Volume varying device for rotating blade type compressor

A compressor and blade technology, applied in the field of variable capacity devices of orbiting vane compressors, can solve the problems of high cost of electrical circuit control devices, increase product manufacturing costs, reduce product competitiveness, etc., to ensure economical use, prevent The effect of wasting electricity, improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

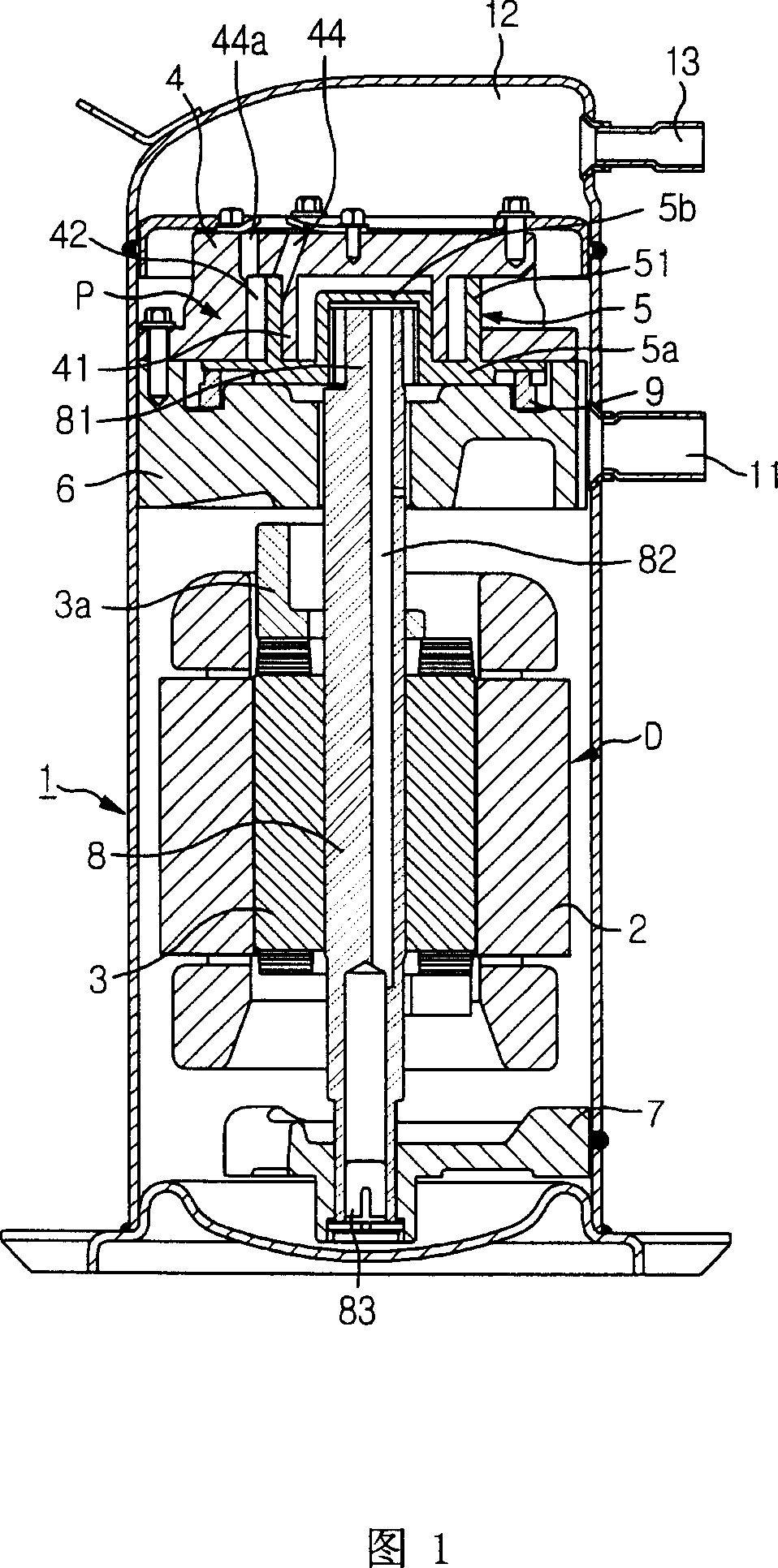

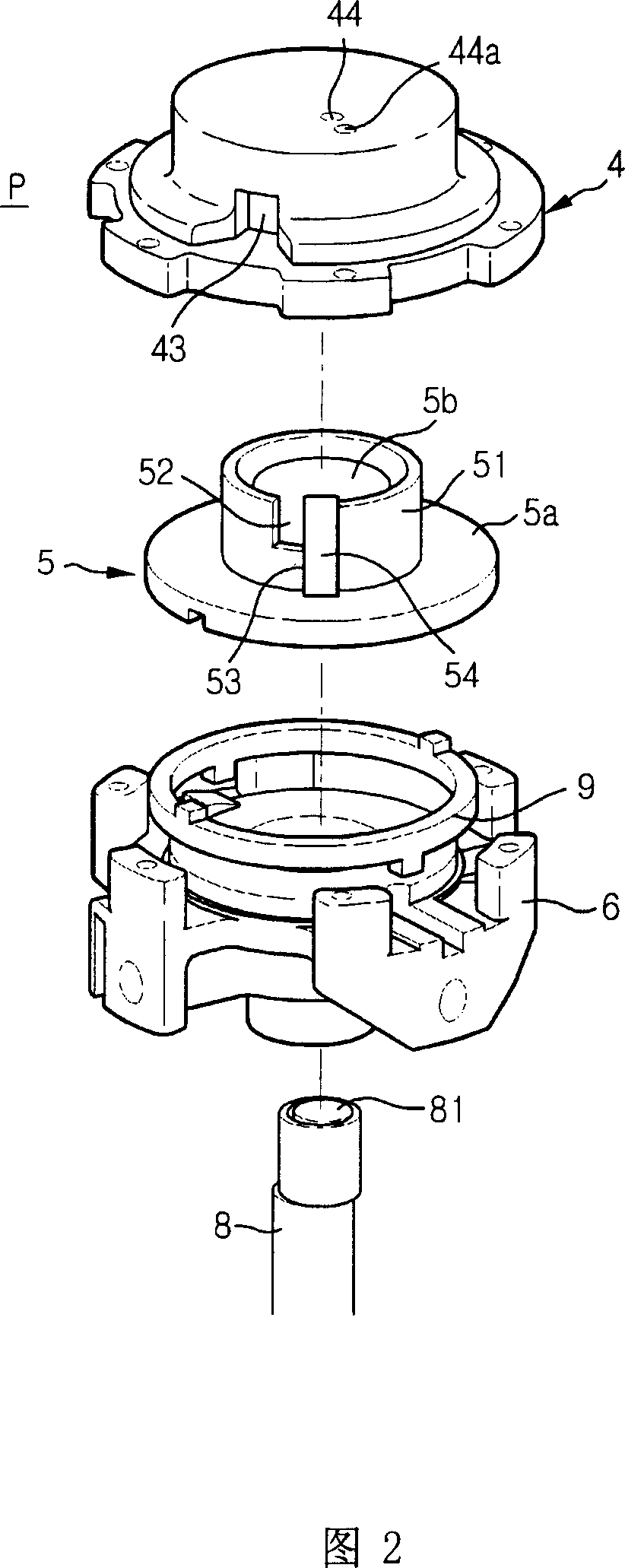

[0048] Below, the structure of the present invention will be described in detail in conjunction with the drawings and embodiments.

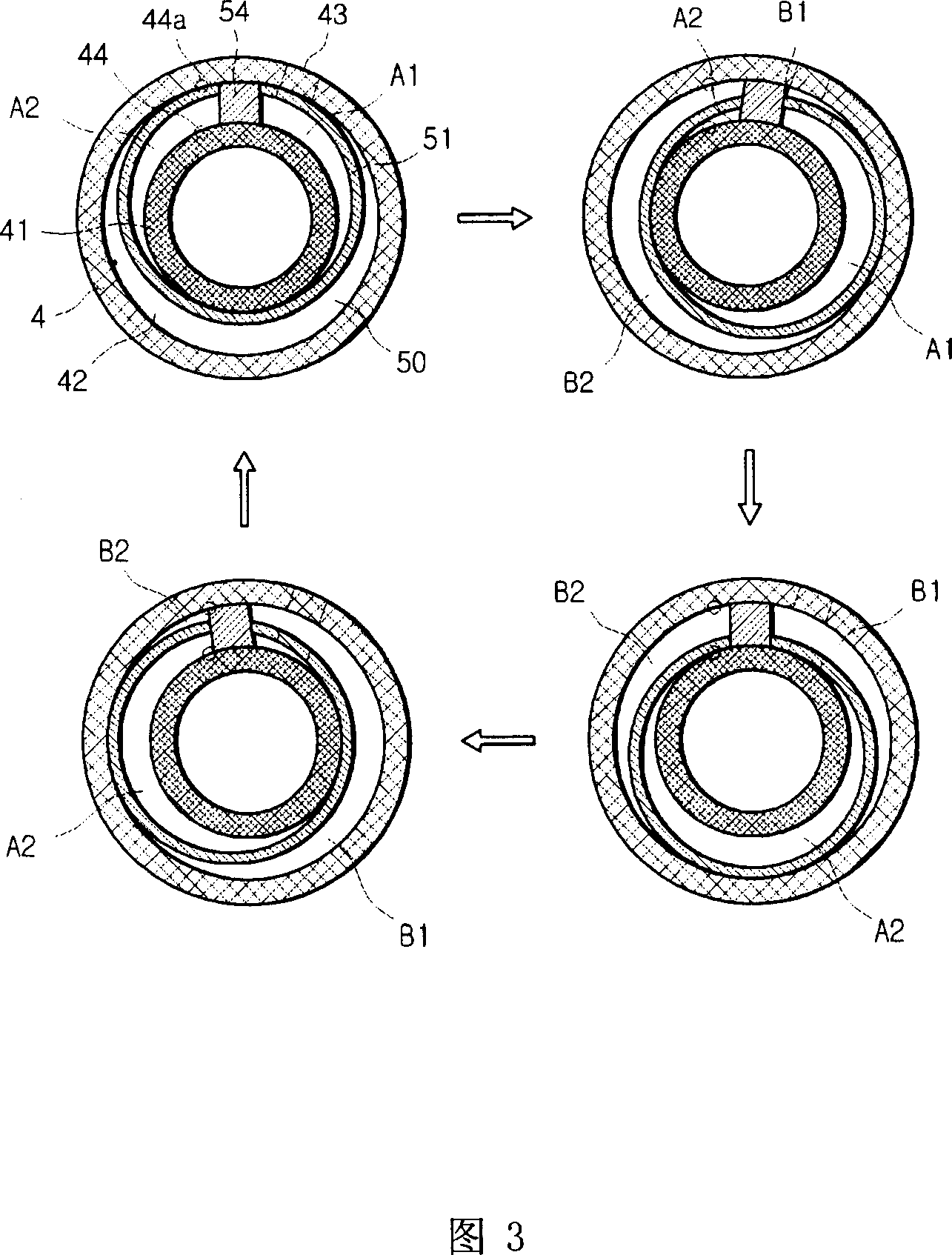

[0049] Fig. 4a and Fig. 4b show the structure and operating state of the embodiment of the present invention, wherein Fig. 4a is a horizontal cross-sectional view showing the state of inner and outer compression.

[0050] As shown in the figure, in the present invention, the linear slider 54 provided with the circular vane 51 is provided with the linear slider 54 of the circular vane 51 on the sliding guide surface 54b of the cylinder 4 formed in parallel to each other, and is in sliding contact with the outer side of the linear slider 54. A slide valve 120 is provided on the inner side of the facing cylinder 4 .

[0051] As shown in FIG. 5a, the linear slider 54 generally forms a right-angled hexahedron structure. On the sliding contact surface corresponding to the sliding guide surface of the cylinder, a pair of sides symmetrical to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com