High molecule polymer diversion and rotation device

A technology of high-molecular polymer and rotating device, which is applied in the field of devices of uniform internal temperature of high-molecular polymer, can solve the problem of not solving the anisotropy of physical properties of products, and achieve the effect of improving the anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

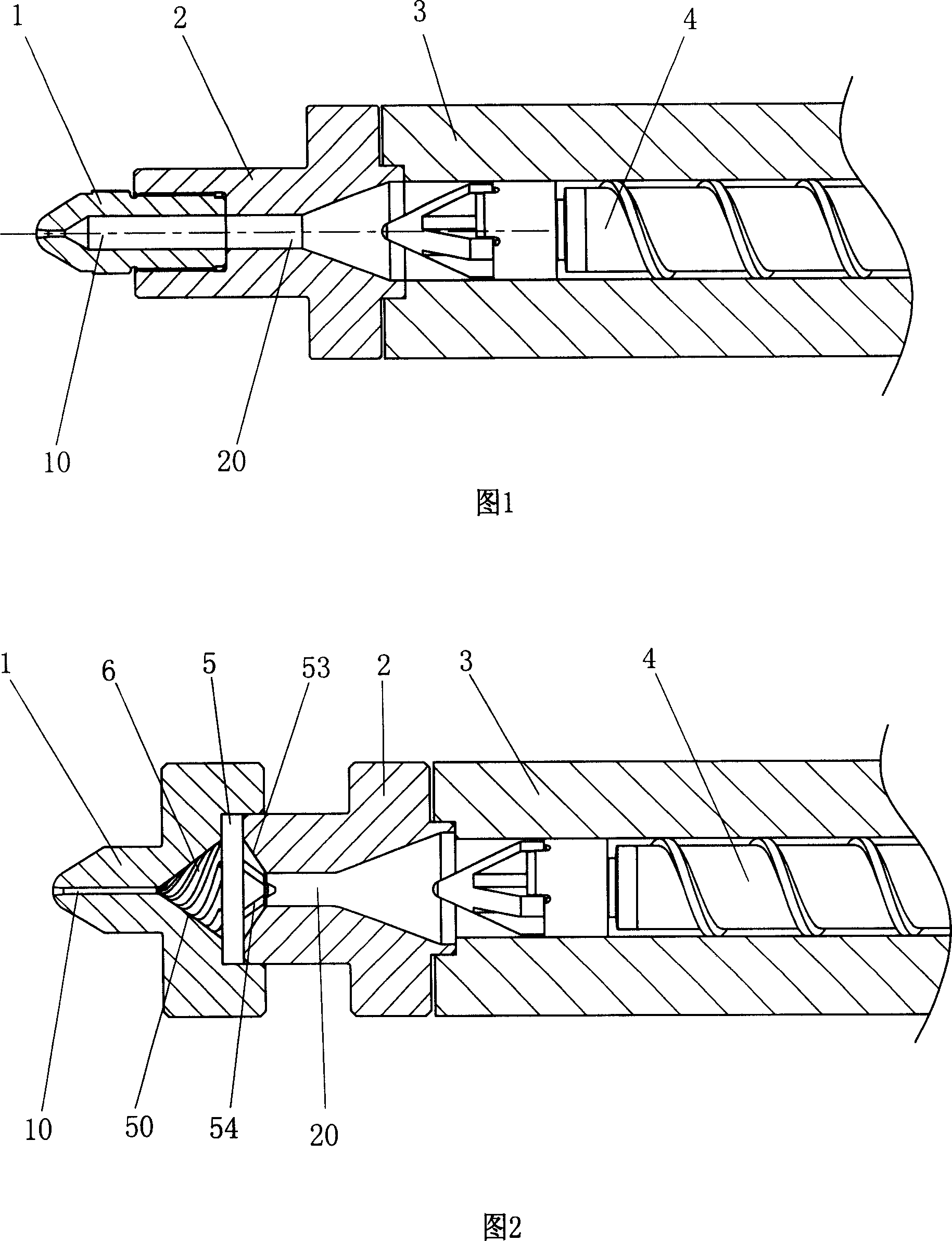

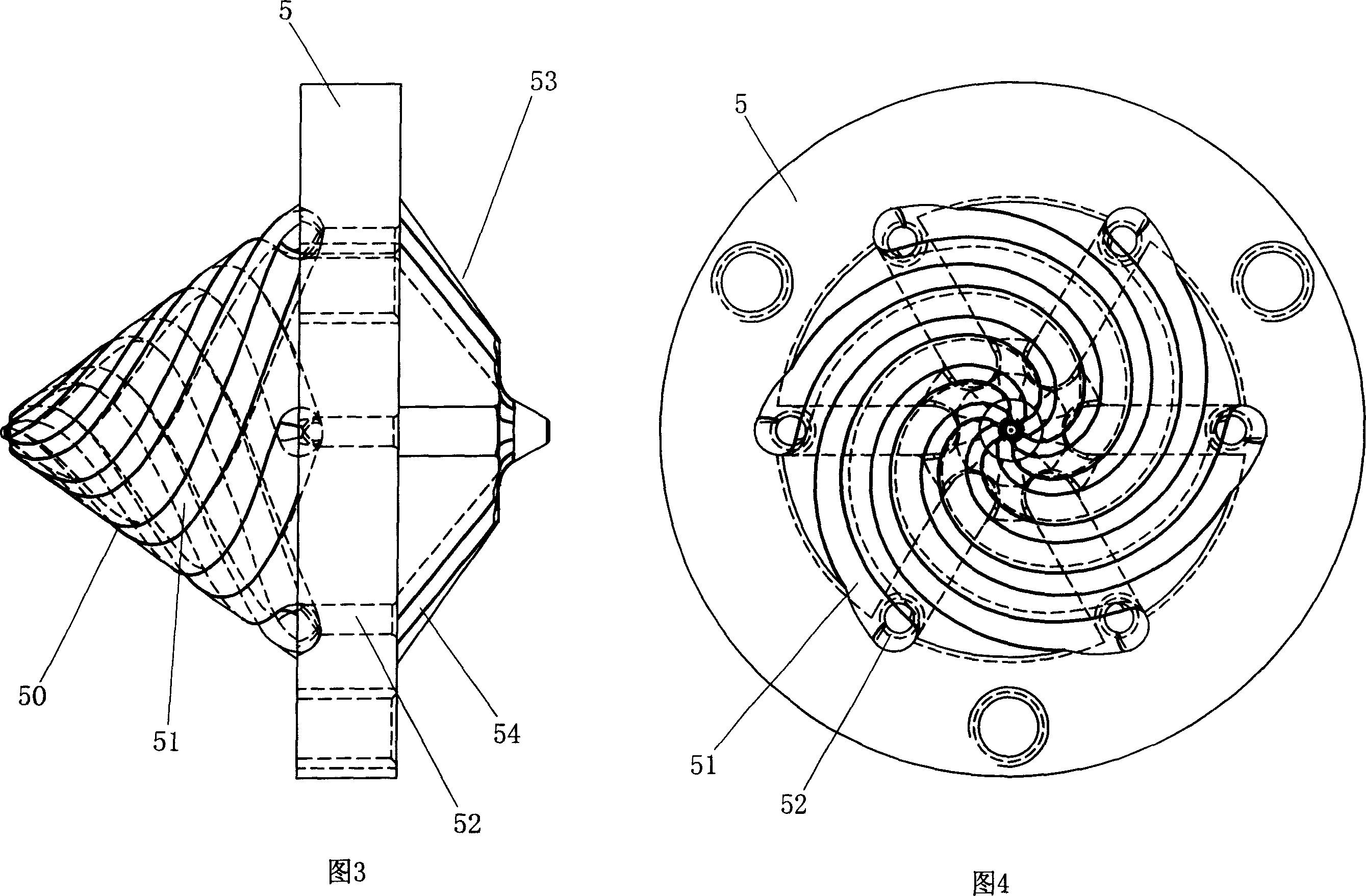

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Referring to Fig. 2 to Fig. 4, a kind of high molecular polymer flow splitting rotating device comprises flange 2, nozzle 1 and main body part 5, and between nozzle 1 and main body part 5, a first conical mating surface 50 and several A spiral flow channel 6 guided by the first conical fitting surface 50, the two ends of the spiral flow channel 6 communicate with the flange 2 and the flow channels (20, 10) of the nozzle 1 correspondingly. The number of said spiral flow channels 6 is at least two. The number of present embodiment is 6.

[0019] The spiral flow channel 6 is matched by several spiral grooves 51 guided by the first conical mating surface 50 that are correspondingly arranged on the main body part 5 or paired on the nozzle 1 and the main body part 5 at the same time. One end of each groove communicates with the flow channel 20 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com