Lamp assembly, discharge lamp and method for constructing such a lamp assembly

A technology for discharge lamps and lamp assemblies, applied in the directions of discharge lamps, discharge tubes, incandescent lamp parts, etc., can solve problems such as lamp cap and lamp holder damage, lamp assembly failure, rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

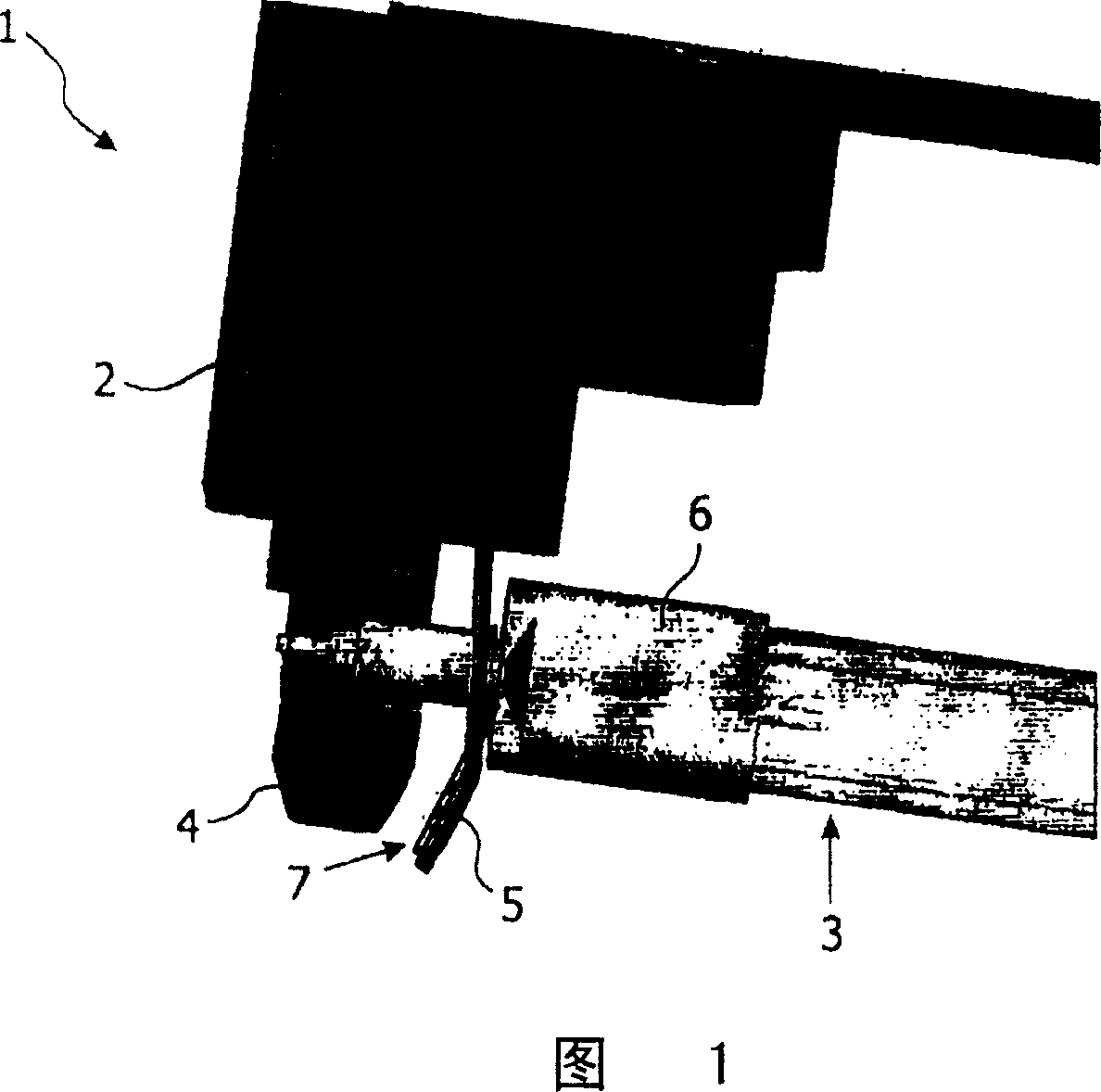

[0015] Figure 1 shows a perspective view of a part of a lamp assembly 1 according to the invention. The lamp assembly 1 comprises a lamp holder 2 and a discharge lamp 3 connected to said lamp holder 2 by two kinds of spring blades 4 and 5 . The first spring leaf 4 consists of two mutually cooperating spring leaves 4 (only one is shown), between which the lamp cap 6 of the discharge lamp 3 is mechanically clamped. The second leaf spring 5 has a slot 7 through which the lamp cap 6 extends. The second spring leaf 5 has a double function, the second spring leaf 7 is simultaneously used to mechanically fix the lamp cap 6 and to establish electrical contact between the lamp holder 2 and the discharge lamp 3 so as to be able to charge the discharge lamp 3 powered by. However, it has been found in practice that an (optimum) electrical contact can only be made if the lampholder 2 and the lamp 3 have ideal mutual dimensions at the same time. For example, if the length of the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com