Starting device for gaseous discharging lamp

A gas discharge lamp and starting device technology, which is applied in the use of gas discharge lamps, lighting devices, electric light sources, etc., can solve the problems of increasing circuit complexity and increasing the overall cost of ballasts, so as to save booster modules and reduce overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

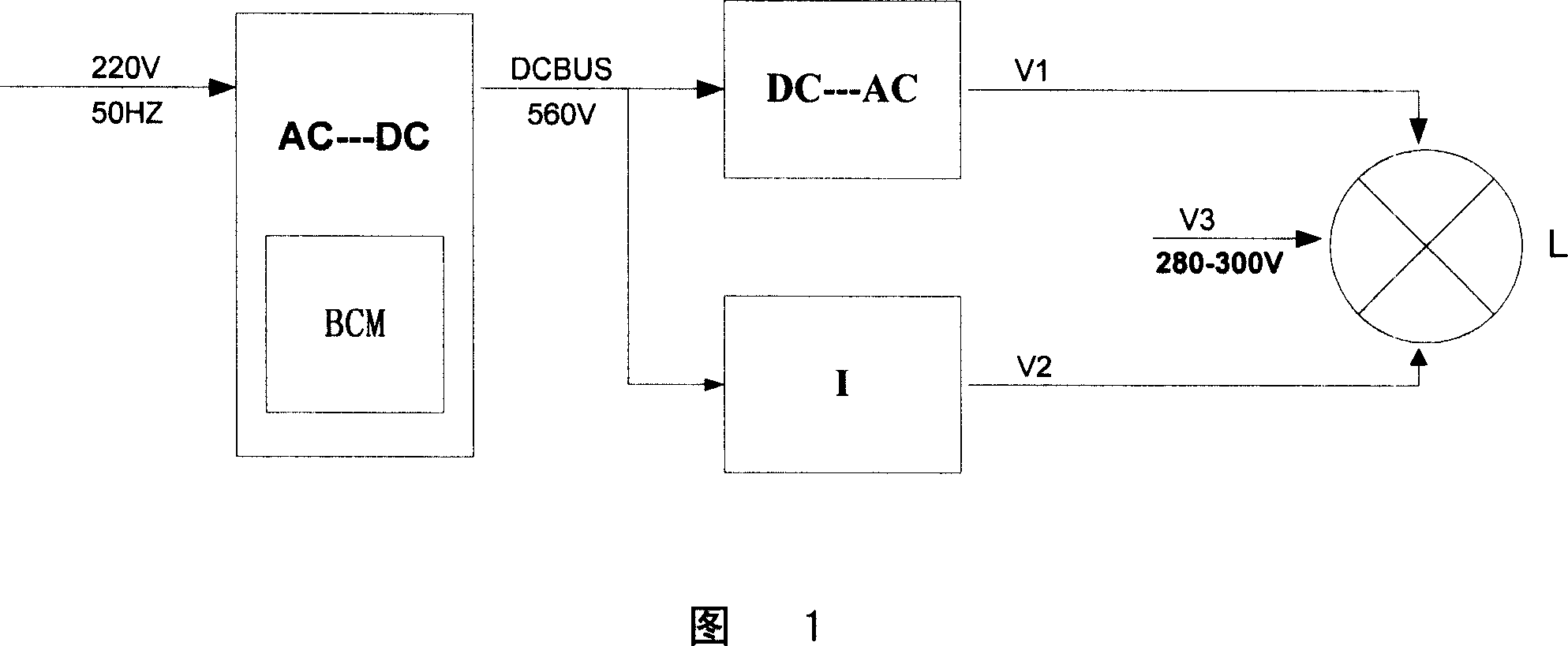

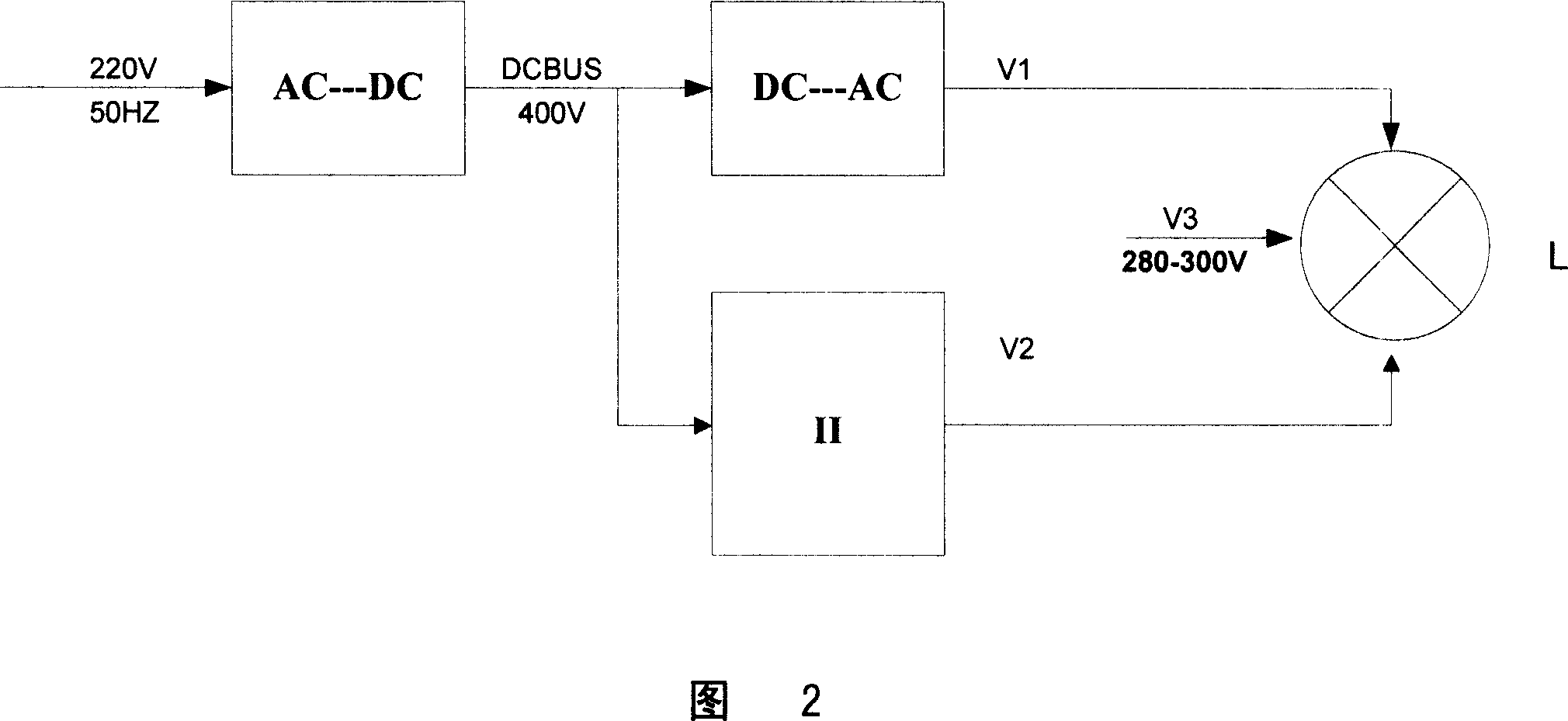

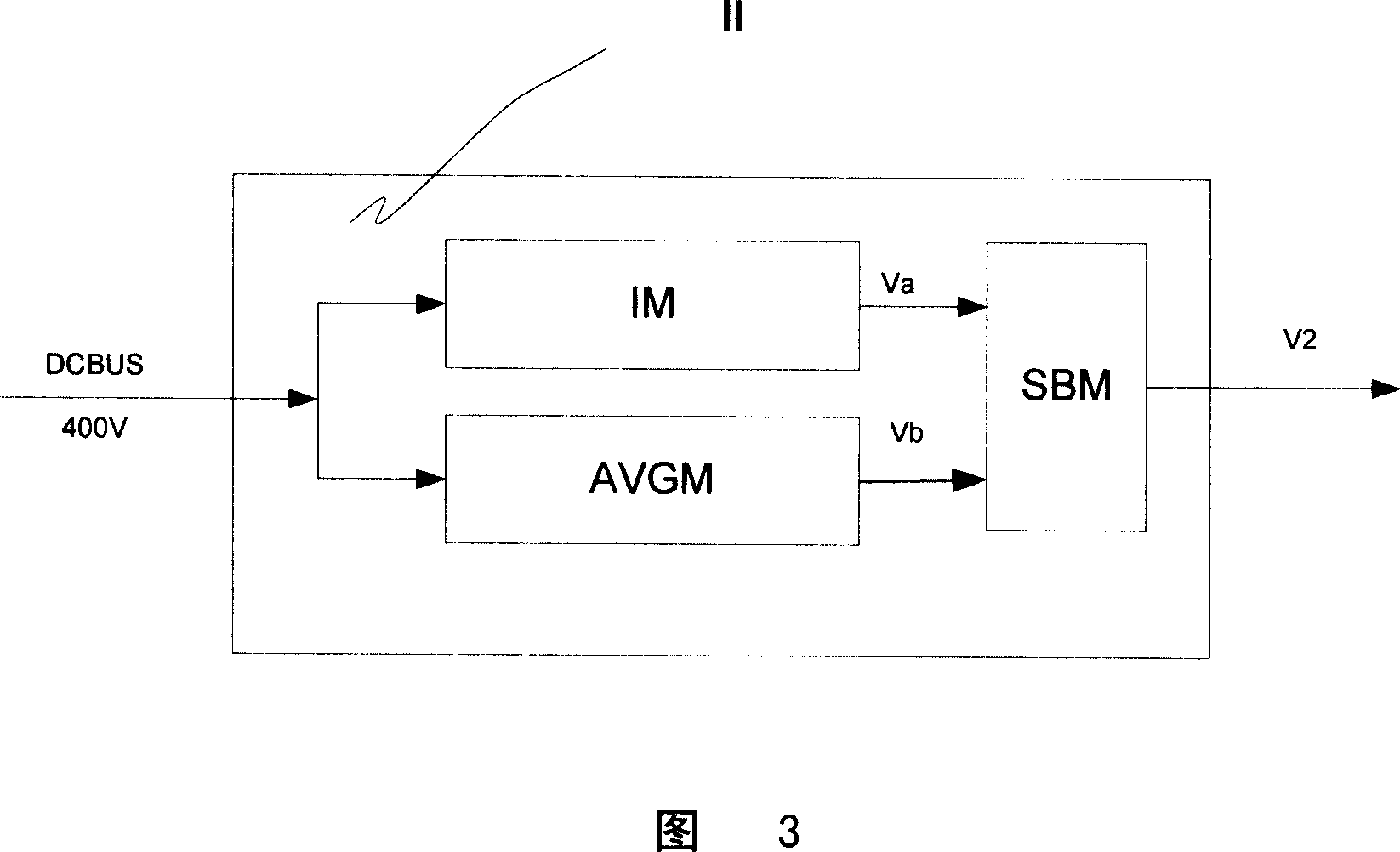

[0030] Fig. 2 is a functional block diagram of starting with the high intensity discharge lamp of the present invention. Compared with the prior art shown in Figure 1, after the improved start-up circuit is adopted, a lower DC bus (DCBUS) voltage can be used, such as a standard DC bus voltage of 400V, without further boosting of the DC bus DCBUS voltage . For example, after rectifying and converting the mains power to obtain the DC bus voltage of 400V, the AC voltage V1 can be obtained directly through an inverter circuit, and the effective value is 200V; Indicates) also outputs a voltage V2 with a certain effective value. The final open-circuit voltage V3 acting on the high-intensity gas discharge lamp will be formed by superimposing the voltage V1 directly output through the inverter circuit and the voltage V2 output through the starting circuit.

[0031] Here, our symbol || represents the effective value of a certain voltage. Since the output voltages V1 and V2 of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com