Injectable block copolymer hydrogel of temperature sensibility(epsi - caprolactone - glycolide)- polyethyleneglycol

A copolymer and temperature-sensitive technology, applied in the direction of organic active ingredients, medical preparations of non-active ingredients, peptide/protein ingredients, etc., can solve problems such as limited application, adverse tissue reactions and side effects, and slow degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Synthesis of P(ε-CL-GA)-PEG-P(ε-CL-GA) Triblock Copolymer

[0022] In a 100 ml reaction vessel equipped with a magnetic stirrer, add 20 grams of polyethylene glycol with a molecular weight of 1540, 40 grams of ε-caprolactone, and 4 grams of glycolide, and then inject 0.5 ml of caprylic acid with a micro syringe Stannous solution (0.1g / ml concentration). The reaction system was decompressed and evacuated at room temperature, and the system was replaced with high-purity nitrogen every half an hour, and this was repeated several times. Polymerization was carried out in an oil bath at 120°C with stirring for 12 hours. After the reaction, the obtained polymer was dissolved in dichloromethane, and then precipitated with a large amount of frozen ether, and the purified polymer was dried in a vacuum oven at 70° C. for 24 hours.

Embodiment 2

[0024] Thermal Transition Properties of P(ε-CL-GA)-PEG-P(ε-CL-GA) Triblock Copolymer

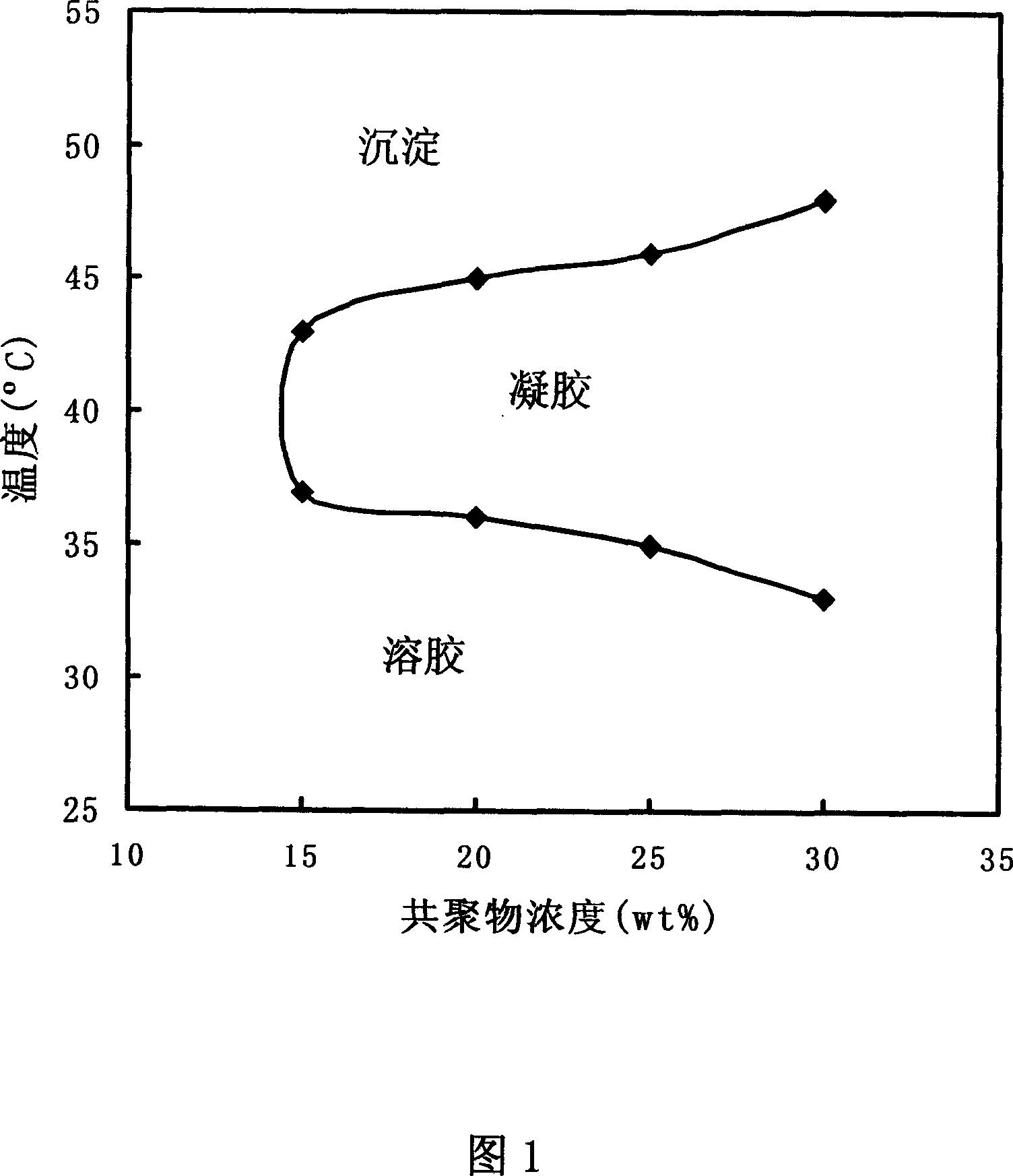

[0025] The sol-gel thermal transition behavior of the triblock copolymer aqueous solution in Example 1 was measured at different concentrations. Aqueous solutions of triblock copolymers with different concentrations were prepared at low temperature, and their viscosity changes between 20-50°C were observed. Gel is defined as the state in which the solution does not flow when the aqueous solution containing the triblock copolymer is inverted. FIG. 1 is a phase diagram showing the sol-gel transition of the triblock copolymer aqueous solution in Example 1. FIG. It can be seen from the phase diagram that when the concentration is above 25wt%, the aqueous solution of the triblock copolymer is a flowable liquid at or below room temperature, but exists in a stable gel state at human body temperature.

Embodiment 3

[0027] Thermosensitivity of ABA Type P(ε-CL-GA)-PEG-P(ε-CL-GA) Triblock Copolymers with Different Compositions

[0028] Using the synthesis method in Example 1, a series of tri-block copolymers with different compositions were synthesized using polyethylene glycol with a molecular weight of 1540 as the hydrophilic segment. The raw material composition ratio of P(ε-CL-GA)-PEG-P(ε-CL-GA) triblock copolymer with reversible thermal transition behavior is shown in the following table:

[0029] Sample No.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com