Method for preventing bach after turnup

A technology for parts and flanging, which is used in the field of preventing parts from springing back after flanging, and can solve the problems of inability to obtain parts and parts springing back.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

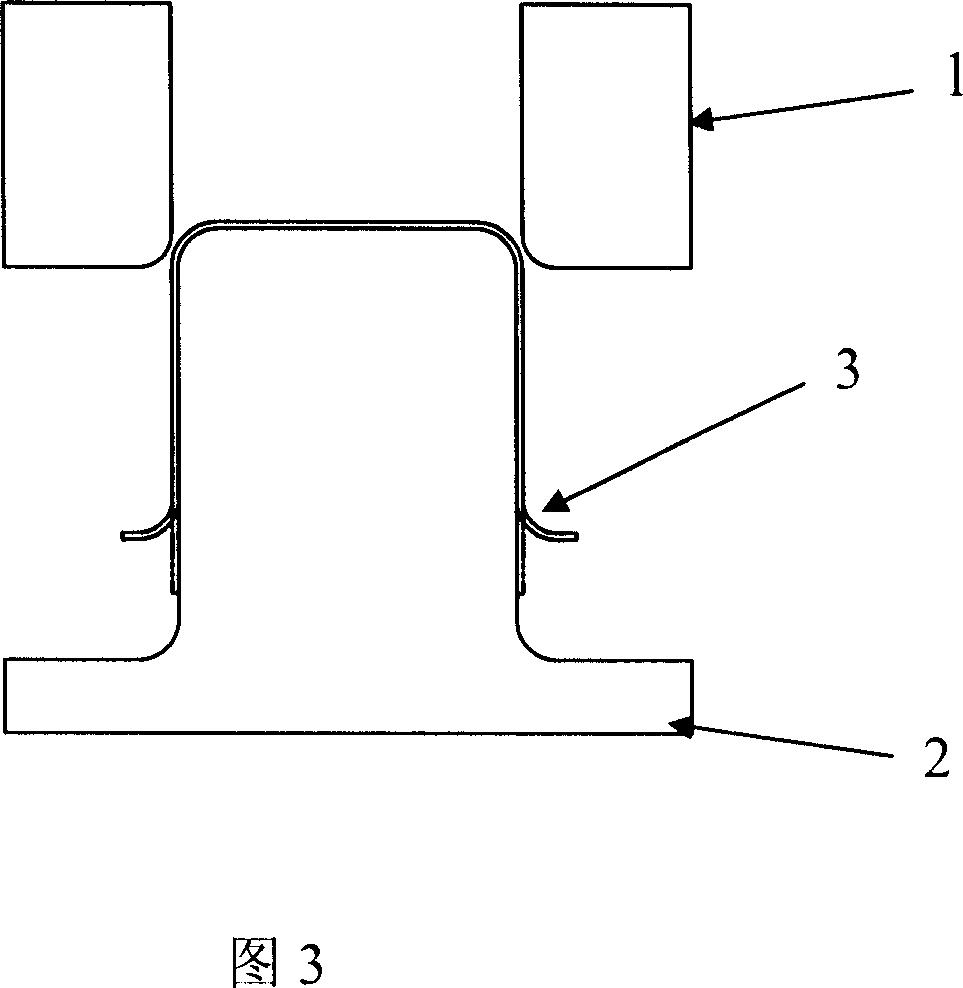

[0022] As shown in the figure, according to the present invention, during the flanging process, one or more ribs 7 in the same direction as the flanging are formed at the flanging place of the part, which can effectively prevent the part from rebounding after flanging .

[0023] The ribs 7 may be arc-shaped concave ribs formed on the outside of the flange of the part. Alternatively, the ribs may also be arc-shaped concave ribs formed on the inner side of the flanging of the part. When there are multiple ribs, the distance between adjacent ribs can be equal or unequal. Specifically, when the flange of the part is even, the spacing between the ribs can be equal; if the flange of the part is not uniform, the part with a large degree of flange can form a plurality of ribs with a relatively small spacing. Ribs, multiple ribs with a relatively large spacing can be formed in the part with a relatively small flanging degree. As a result, more ribs are formed in the part with a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com