Power transmission line ground wire splicing sleeve correction device

A technology of transmission lines and ground wires, which is applied in the field of correction devices for transmission line ground wires, can solve the problems of poor crimping position in the air, heavy equipment, and difficult construction, so as to achieve simple use, improve construction quality and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

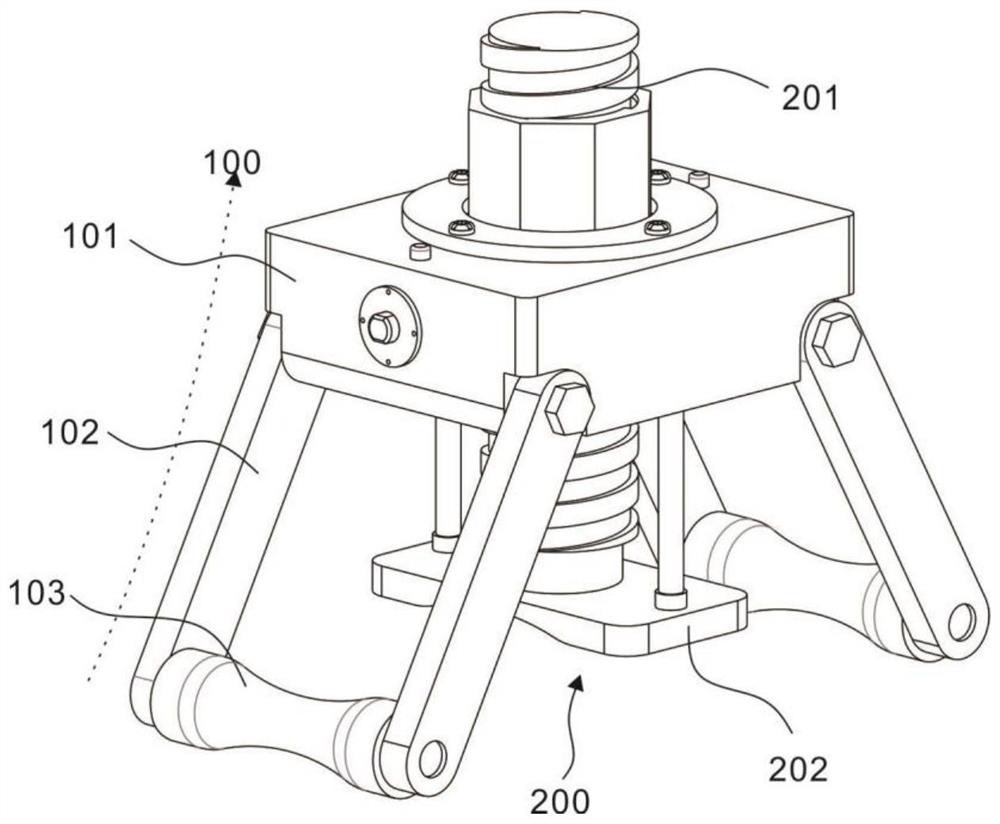

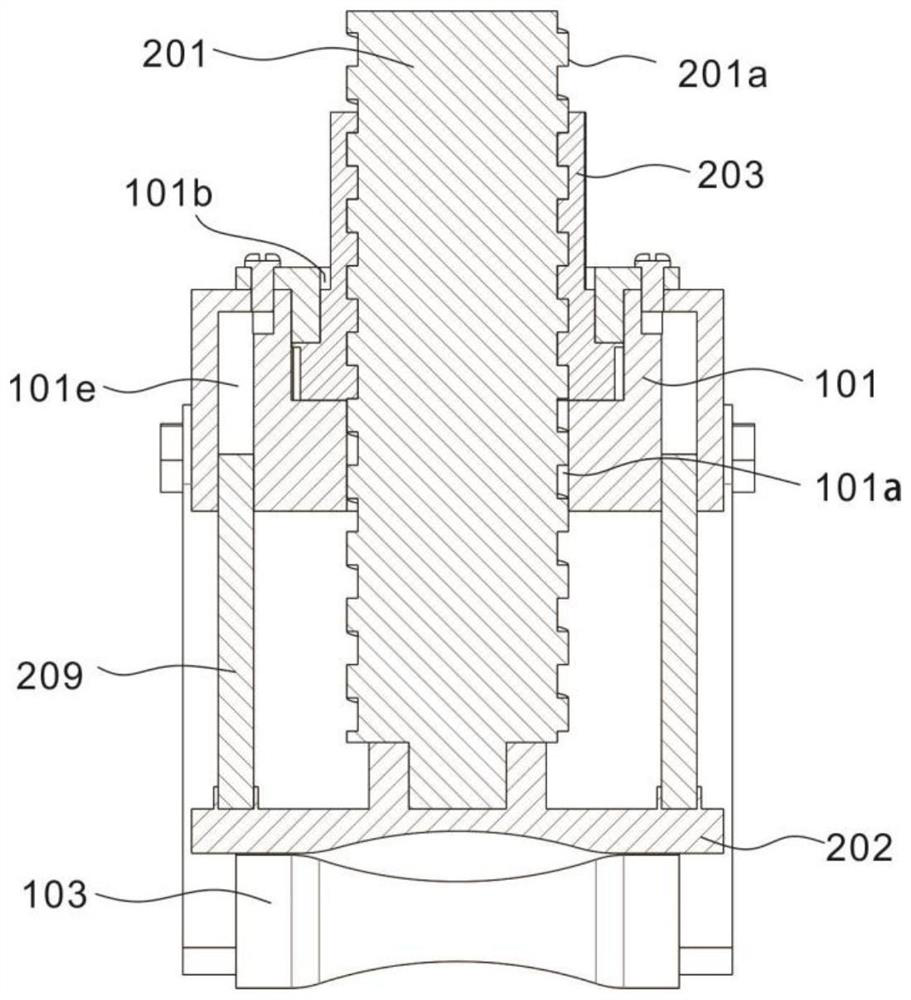

[0030] refer to figure 1 , the present embodiment provides a power transmission line conductor and ground wire connection tube correction device, which is used to correct the bent connection tube to a straight state, which is easy to use, and mainly includes a correction unit 100 and an adjustment unit 200; specifically, the correction unit 100, including a base 101, a correction rod 102, and a correction column 103. There are two pairs of correction rods 102, which are symmetrically connected to both ends of the base 101. The ends of the two pairs of correction rods 102 are hinged with a correction column 103. On the base 101 A through hole 101a is provided; the base 101 is used to carry the entire correction unit 100 and the adjustment unit 200, the correction rod 102 is rod-shaped, and can be fixed at both ends of the base 101 by welding, and the correction rod 102 is provided with two pairs of , and each team is located at both ends of the base 101, and the correction rods...

Embodiment 2

[0034] refer to Figure 1-7 , is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and is different from the previous embodiment in that: in the process of rectifying the connecting pipe, sometimes a long period of rectification is required, but in embodiment 1 During the rectification process, the elastic force of the connecting tube may cause the adjustment rod 201 to loosen in the through hole 101a and the rectification fails. Therefore, this embodiment also provides a device capable of restricting the movement of the adjustment rod 201 during the correction, so as to prevent the adjustment rod 201 from loosening.

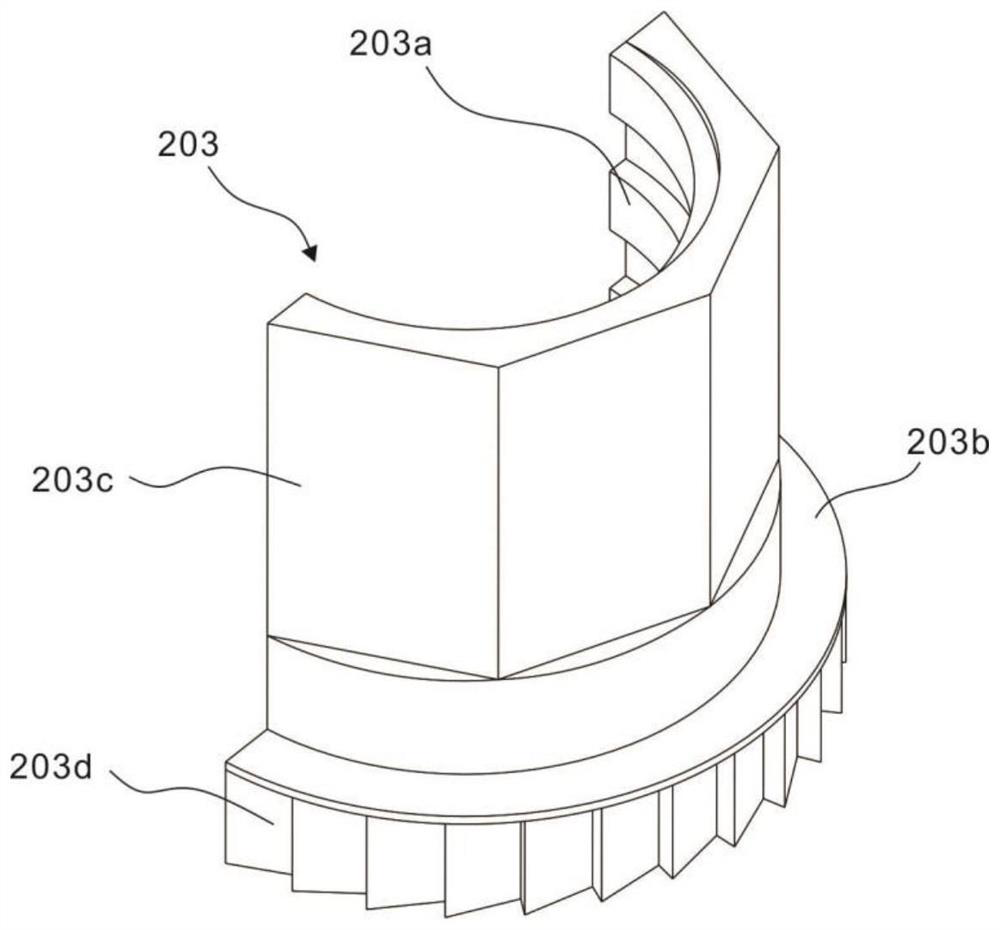

[0035] Specifically, the peripheral surface of the adjustment rod 201 is provided with an external thread 201a, and the adjustment unit 200 also includes a rotating member 203. The connection forms a screw action, wherein the adjusting rod 201 can only move along the axial direction of the through hole 101a, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com